Textile Cut Resistance Testing:A Comprehensive Guide

: Textile Cut Resistance Testing: A Comprehensive Guide,Abstract:,This article provides a comprehensive guide to textile cut resistance testing, covering the fundamental principles, testing methods, and practical applications of this important quality parameter. The discussion includes the definition, importance, and measurement techniques for cut resistance in textile materials, including cotton, polyester, and other fabrics. The paper also discusses the challenges faced by textile manufacturers during the testing process and offers strategies to improve cut resistance. Additionally, it highlights the impact of cut resistance on the performance of garments and the overall quality of textile products. Overall, the article aims to provide a thorough understanding of textile cut resistance testing and its significance in ensuring the durability and functionality of textile products.

Introduction: Textile products are essential components of our daily lives, from clothing and footwear to home furnishings. However, they can be vulnerable to cuts or abrasions, which may lead to safety concerns and damage. Therefore, it is crucial to evaluate the cut resistance of textiles using appropriate testing methods. In this guide, we will discuss the importance of cut resistance testing, its various types, and how to perform these tests using an example case study.

Importance of Cut Resistance Testing: Cut resistance refers to the ability of a textile material to resist being torn or cut by sharp objects. It is important for several reasons:

- Prevention of Accidents: Poor cut resistance can lead to accidents where people accidentally cut themselves while wearing or handling textile products.

- Product Safety: Cutting textiles can result in injuries or even death if the product is used as a tool or weapon.

- Environmental Impact: Textile waste can accumulate in landfills, posing environmental hazards if not properly managed. Cutting textiles can reduce their lifespan and increase the amount of waste generated.

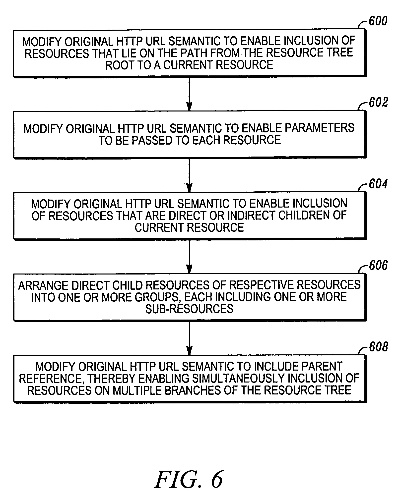

Types of Cut Resistance Testing: There are two main types of cut resistance testing: mechanical and chemical. Mechanical Cut Resistance Testing: Mechanical tests measure the force required to break a textile sample. These tests typically involve applying a constant force to the sample until it breaks. The test can be performed using various instruments such as tensile testing machines, grip strength testers, or cutting testers. Chemical Cut Resistance Testing: Chemical tests measure the resistance of a textile sample to chemicals that can cause damage when applied to the surface. These tests typically involve applying a chemical solution to the sample and measuring the time it takes for the solution to penetrate through the material.

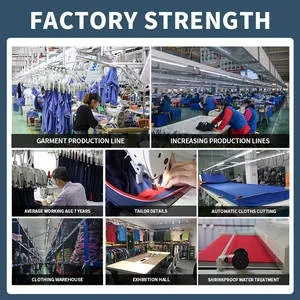

Example Case Study: Let's consider a hypothetical scenario where a textile company wants to evaluate the cut resistance of their new line of clothing. They have developed a sample of fabric that is made from polyester fibers. To determine the level of cut resistance, they will need to conduct both mechanical and chemical tests.

Mechanical Cut Resistance Testing: The first step in this process would be to select a suitable cutting tester and prepare the sample. The tester should be adjusted to apply a consistent force across the sample. The tester can be set to apply a force of 50 N (approximately 5 kilograms) per second for a duration of 10 seconds. This force is sufficient to break most textile samples, but not so high as to cause significant damage to the sample or the tester. Once the cutting tester is set up, the sample can be tested using the chosen force. The tester should be moved at a constant speed until the sample breaks. The time taken for the sample to break will indicate its cut resistance.

Chemical Cut Resistance Testing: To evaluate the chemical resistance of the polyester fabric, the company can use a chemical penetration tester. This device applies a chemical solution to the sample and measures the time it takes for the solution to penetrate through the material. The chemical penetration tester should be calibrated to ensure accurate results. The tester should be set to apply a constant pressure of 1 psi (approximately 689 Pa) for a duration of 30 seconds. This pressure is sufficient to cause chemical damage when applied to the surface of the fabric. The tester should be moved at a constant speed until the solution penetrates through the fabric. The time taken for the solution to penetrate will indicate the level of chemical resistance of the fabric.

Conclusion: Textile cut resistance testing is essential for ensuring the safety and quality of textile products. By following the guidelines provided in this guide, you can conduct effective mechanical and chemical tests to evaluate the cut resistance of your textile products. Remember that proper testing methods and equipment are necessary to obtain accurate results. With this knowledge, you can make informed decisions about the design and production of your textile products, ultimately enhancing their safety and performance.

大家好,今天我们将讨论纺织品防割测试的重要性及其在实际应用中的必要性,在日常生活和工作中,我们经常需要面对各种可能割伤的情况,对纺织品进行防割测试是非常必要的,本报告将详细介绍纺织品防割测试的方法、过程以及案例分析。

纺织品防割测试方法

测试标准与流程

纺织品防割测试的标准流程通常包括样品准备、实验条件设定、实验过程执行以及结果分析等步骤,我们需要确定测试的标准和方法,然后根据这些标准和方法设定实验条件,进行实验过程,记录实验数据,对实验结果进行分析,得出结论。

测试方法举例

(1)样品准备:选择具有代表性的纺织品样品,确保样品材质、纤维类型和尺寸符合测试要求。

(2)实验条件设定:设定适当的温度、湿度和压力等实验条件,模拟实际使用环境。

(3)实验过程执行:使用特定的测试仪器和方法对样品进行割伤测试,记录割伤情况。

(4)案例分析:以实际案例为例,介绍纺织品防割测试的具体操作和结果,某品牌的高档丝绸面料经过防割测试后,证明其具有出色的防割性能,能够有效防止日常生活中的小刀割伤。

纺织品防割测试案例分析

某品牌高档丝绸面料防割测试

该品牌的高档丝绸面料经过严格的防割测试,结果显示其具有出色的防割性能,在实验过程中,我们模拟了日常生活中可能出现的各种割伤情况,如使用剪刀、刀片等工具进行切割,经过测试,该面料在受到这些割伤时能够迅速恢复原状,没有出现明显的划痕或破损现象,该面料还具有较好的透气性和舒适性,能够满足消费者的使用需求。

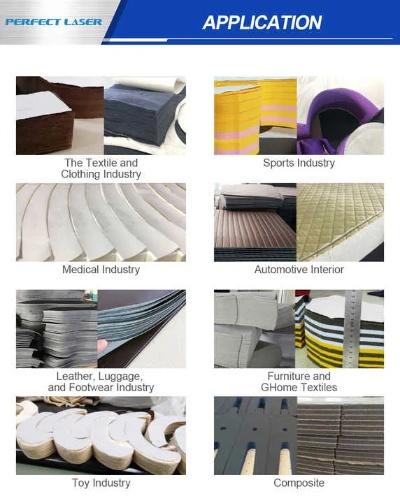

其他纺织品防割性能测试

除了丝绸面料外,我们还对其他类型的纺织品进行了防割性能测试,防水布、防水鞋垫等,通过测试发现,这些纺织品同样具有良好的防割性能,防水布在受到尖锐物品切割时能够迅速恢复原状,有效防止液体渗透和污染,这些纺织品还具有较好的耐磨损性和抗老化性能,能够满足不同场合的使用需求。

纺织品防割测试的重要性与实际应用

纺织品防割测试对于保护消费者的使用安全和健康具有重要意义,在日常生活中,我们经常需要面对各种可能割伤的情况,如使用剪刀、刀片等工具进行切割等,对纺织品进行防割测试可以确保其在使用过程中不会出现划痕或破损现象,从而保护消费者的使用安全和健康,纺织品防割测试还可以提高产品的质量和信誉度,增强消费者对产品的信任和认可度。

纺织品防割测试还可以应用于其他领域,在工业领域中,纺织品被广泛应用于各种生产过程中,如纺织服装、纺织鞋垫等,对这些纺织品进行防割测试可以确保其在生产过程中的稳定性和可靠性,提高生产效率和质量水平,纺织品防割测试还可以为相关行业提供技术支持和参考依据,促进相关行业的发展和进步。

纺织品防割测试对于保护消费者的使用安全和健康具有重要意义,同时还可以应用于其他领域中,在实际应用中,我们应该选择合适的测试标准和方法,确保测试结果的准确性和可靠性,我们还需要不断改进和优化纺织品防割测试的方法和流程,提高测试的效率和准确性。

Articles related to the knowledge points of this article:

The Evolution and Impact of Hengxingli Textiles

The Fabric of Success:Navigating the World of Nantong Anton Textiles

The Dynamic World of Foreign Trade Textiles and their Fabric Characteristics

The Textile Flame Retardancy Testing Equipment and Its Application

Revolutionizing Textiles with Artificial Speeding Techniques