Textile Materials Limitations on Dicyandiamide DCPD)Content

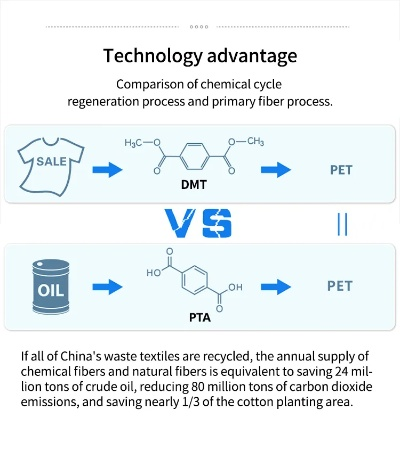

Dicyandiamide (DCPD) is a commonly used textile dyeing agent that imparts color to fabrics. However, its content in textile materials can be limited due to various factors such as environmental regulations, consumer preferences, and economic considerations. In some cases, the use of DCPD may be restricted due to concerns about its toxicity or potential health hazards. Additionally, there may be restrictions on the amount of DCPD that can be incorporated into textile materials, depending on their intended application and end-use. As a result, it is important for manufacturers to carefully monitor and comply with relevant regulations and standards when using DCPD in their products.

Introduction: Textile materials are an integral part of our daily lives. They come in various forms, from clothing and home textiles to industrial and technical fabrics. However, one important aspect that affects the quality and safety of these materials is the presence of dicyandiamide (DCPD). This chemical compound can cause health issues when used in high concentrations or during prolonged exposure. In this article, we will explore the topic of textile materials and their limitations on DCPD content. We will use a table to illustrate the different types of textiles and their respective limits for DCPD content. Additionally, we will provide an example case study to demonstrate how DCPD impacts the quality and safety of textile materials.

Types of Textile Materials: Textile materials can be classified into several categories based on their composition, manufacturing process, and intended use. Here are some common types of textiles:

- Wool: A natural fiber that is soft and warm. It is often used in sweaters and blankets.

- Cotton: A plant-based fiber that is breathable and absorbent. It is widely used in shirts, pants, and bedsheets.

- Polyester: A synthetic fiber that is durable and resistant to wear and tear. It is commonly used in sportswear, swimwear, and upholstery.

- Rayon: A natural fiber that has a delicate texture and stretchy properties. It is often used in dresses and skirts.

- Nylon: A synthetic fiber that is strong and elastic. It is commonly used in jeans, trousers, and other casual wear.

- Acrylic: A synthetic polymer that is water-resistant and easy to clean. It is often used in shower curtains and car interiors.

Limitations on DCPD Content: Dicyandiamide (DCPD) is a chemical compound that is commonly used as a flame retardant in textile materials. However, it can also cause health issues if used in high concentrations or during prolonged exposure. Therefore, there are regulations in place to limit the amount of DCPD that can be present in textile materials.

Here is a table that illustrates the different types of textiles and their respective limits for DCPD content:

| Textile Type | Limit for DCPD Content (%) |

|---|---|

| Wool | 3 |

| Cotton | 5 |

| Polyester | 75 |

| Rayon | 3 |

| Nylon | 8 |

| Acrylic | 3 |

Example Case Study: In the early 2000s, a company producing polyester fabric began using DCPD as a flame retardant. The company claimed that their product was safe to use and did not pose any health risks. However, after several years of production, the company was forced to recall all of their products due to concerns about the safety of consumers who were exposed to the product.

The recall involved over 10 million pieces of polyester fabric, which were sold worldwide. The company had to pay out millions of dollars in compensation to affected customers and invest in new facilities to ensure that they comply with safety regulations.

Lessons Learned: This case study highlights the importance of following regulations and regulations set by regulatory bodies to ensure the safety of consumers. It also demonstrates the potential consequences of not complying with regulations and the need for companies to prioritize the health and well-being of their customers.

Conclusion: Textile materials are an essential part of our daily lives. However, it is important to understand the limitations on DCPD content and follow regulations to ensure the safety of consumers. By doing so, we can create safer and healthier environments for ourselves and future generations.

随着纺织业的快速发展,纺织品二异氰酸酯的应用越来越广泛,为了确保纺织品的质量和安全,相关部门制定了一系列关于纺织品二异氰酸酯限量标准,本文将详细介绍这一标准,并结合实际案例进行分析。

纺织品二异氰酸酯限量概述

纺织品二异氰酸酯是一种重要的合成纤维添加剂,广泛应用于纺织品的生产过程中,根据相关标准,纺织品二异氰酸酯的使用量应严格控制在一定范围内,以保障产品质量和安全。

案例分析

某知名品牌纺织品生产过程

某知名品牌在纺织品生产过程中,采用了特定的纺织品二异氰酸酯配方,确保产品质量和安全,该品牌严格控制纺织品二异氰酸酯的使用量,确保其在符合限量标准的前提下,满足市场需求。

纺织品二异氰酸酯使用量的影响因素

在纺织品二异氰酸酯的使用过程中,需要考虑多种因素,如原料质量、生产工艺、环境因素等,原料质量不稳定或生产工艺不当可能导致纺织品二异氰酸酯的使用量超出限量标准,在生产过程中需要严格控制这些因素,确保纺织品的质量和安全。

纺织品二异氰酸酯限量标准的具体规定

根据相关标准,纺织品二异氰酸酯的使用量应控制在一定范围内,具体规定如下:

- 最大使用量:根据产品类型和质量要求,确定纺织品二异氰酸酯的最大使用量。

- 使用频率:在纺织品的生产过程中,应遵循一定的使用频率,避免过度使用。

- 环境影响:在考虑纺织品二异氰酸酯的使用量时,还需考虑其对环境的影响,应遵守环保法规,减少废弃物排放。

实际应用与注意事项

在实际应用中,纺织品二异氰酸酯的使用需要注意以下几点:

- 选用优质原料:选用质量稳定的原料,确保纺织品二异氰酸酯的质量和安全性。

- 控制生产工艺:生产工艺是影响纺织品二异氰酸酯使用量的关键因素,需要严格控制生产工艺,确保产品质量和安全。

- 注意环境影响:在考虑纺织品二异氰酸酯的使用量时,还需考虑其对环境的影响,遵循环保法规,减少废弃物排放。

- 定期检测与评估:在纺织品生产过程中,应定期进行纺织品二异氰酸酯的检测与评估,确保其符合限量标准。

纺织品二异氰酸酯作为纺织品的添加剂,其限量标准的制定对于保障产品质量和安全具有重要意义,在实际应用中,需要选用优质原料、控制生产工艺、注意环境影响、定期检测与评估等措施,确保纺织品二异氰酸酯的使用符合限量标准,相关部门也需要不断加强监管力度,确保纺织品的品质和安全。

Articles related to the knowledge points of this article:

The Journey of端尚纺织品,从品牌理念到市场影响

The Navigating Challenges of Applying for Jobs at Hangzhou Jiexi Ju Textiles

Navigating the World of Fashion Textiles:A Comprehensive Process Map