Textile Thickness Measurement Techniques and Their Impact on Manufacturing

The article discusses the various techniques used for measuring textile thickness, including calipers, gauges, and tensometers. The impact of these methods on manufacturing is also examined, highlighting how they affect the quality and consistency of textile products. It is important to note that the choice of measurement technique can have a significant impact on the overall production process, from raw material selection to final product assembly. Therefore, it is essential for manufacturers to carefully consider their options when selecting the appropriate technique for measuring textile thickness.

Introduction: In the textile industry, determining the thickness of fabrics is crucial for quality control, product development, and compliance with regulatory standards. Textile thickness measurement is essential for ensuring uniformity and consistency in production, which directly impacts the final product's appearance, durability, and performance. This article explores the various techniques used to measure textile thickness and their practical applications in the manufacturing process.

Techniques for Textile Thickness Measurement:

-

Tape-Based Thickness Gauges:

- These are simple and cost-effective tools that use adhesive tape to measure the thickness of fabrics. They are widely used in the retail industry and in the garment industry for quick and easy measurements.

- Advantages: Easy to use, portable, and suitable for small batch production.

- Disadvantages: Limited accuracy compared to other methods, may not be accurate for thicker fabrics.

-

Mechanical Thickness Meters:

- These instruments use a motorized arm to apply pressure to the fabric and calculate its thickness based on the displacement.

- Advantages: High precision, accurate results, and can measure different types of fabrics.

- Disadvantages: Requires maintenance, can be expensive, and may not be suitable for small batch production.

-

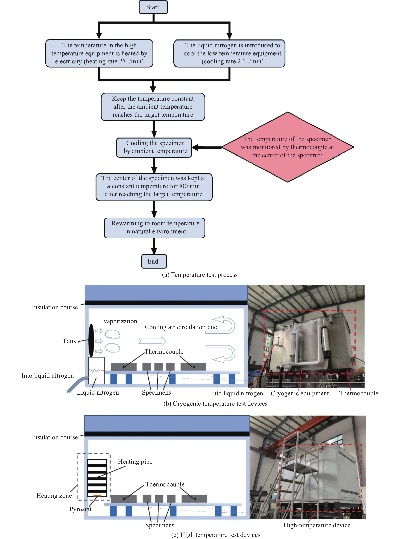

Ultrasonic Thickness Meters:

- These instruments use high-frequency sound waves to generate vibrations in the fabric and measure the time it takes for these vibrations to return to a stable state.

- Advantages: Accurate, non-contact measurement, and can measure both solid and liquid materials.

- Disadvantages: Requires professional setup and maintenance, may not be applicable for all types of fabrics.

-

Infrared Thickness Meters:

- These instruments use infrared radiation to measure the distance between two objects and calculate their thickness based on the principle of time delay.

- Advantages: Non-contact measurement, fast measurement speed, and can measure different types of materials.

- Disadvantages: Can be affected by external factors such as temperature and humidity, and may not be suitable for very thin or delicate materials.

-

Laser Measurement Systems:

- These systems use laser technology to measure the distance between two points on the fabric surface.

- Advantages: High precision, accurate results, and can measure any type of material.

- Disadvantages: Expensive, requires specialized equipment, and may not be suitable for small batch production.

Case Study: Consider a textile company that produces high-quality sportswear. To ensure the fabrics meet strict thickness requirements, they invest in a combination of tape-based thickness gauges and an ultrasonic thickness meter. The company uses the tape gauges to quickly check the thickness of the fabric during the initial stages of production, while the ultrasonic thickness meter provides more accurate measurements for subsequent processes. By using both methods, the company ensures consistent quality throughout the entire manufacturing process.

Conclusion: Textile thickness measurement plays a critical role in the manufacturing process, from raw material procurement to finished product inspection. The choice of measurement technique depends on the specific needs of the industry and the desired level of accuracy. Companies should consider a combination of different methods to optimize their thickness measurement processes and achieve the best results for their products. With the right tools and techniques, textile manufacturers can deliver high-quality products that meet customer expectations and industry standards.

公司简介

我们是一家专注于纺织品测厚仪研发与销售的公司,致力于为客户提供高品质、高精度的纺织品测厚解决方案,我们的产品广泛应用于纺织、服装、家居装饰等行业,旨在满足不同客户的需求。

产品介绍

产品种类

我们的纺织品测厚仪是一款多功能、高精度的测量设备,适用于各种纺织材料的厚度测量,产品包括手持式测厚仪、固定式测厚仪等多种型号,可根据客户需求进行选择。

工作原理

我们的纺织品测厚仪采用先进的传感器技术,能够快速、准确地测量纺织材料的厚度,传感器与设备内部算法相结合,能够实现高精度的测量结果,我们还提供多种测量模式,以满足不同行业和客户的需求。

案例分析

为了更好地展示我们的产品和服务,我们选取了一个具体的案例进行说明。

纺织品测厚仪在某服装品牌的应用

某服装品牌在采购过程中遇到了纺织品厚度检测的问题,由于该品牌需要精确测量不同款式和颜色的纺织品厚度,因此他们选择了我们公司的纺织品测厚仪。

使用过程:该服装品牌首先向我们公司咨询了关于纺织品测厚仪的详细参数和功能,随后,我们提供了专业的技术支持和售后服务,帮助该品牌安装和调试测厚仪,在使用过程中,该品牌反馈称测厚仪操作简便、测量精度高,能够满足其快速检测纺织品厚度的需求。

效果评估:经过一段时间的使用,该服装品牌反馈称使用我们的纺织品测厚仪能够准确测量不同款式和颜色的纺织品厚度,大大提高了生产效率和产品质量,该品牌对我们的产品和服务表示满意,并计划在未来继续选择我们的产品和服务。

产品特点与优势

- 高精度测量:我们的纺织品测厚仪采用先进的传感器技术,能够快速、准确地测量纺织材料的厚度,误差极低。

- 多功能应用:我们的产品适用于各种纺织材料的厚度测量,能够满足不同行业和客户的需求,我们还提供多种测量模式和功能选项,以满足不同客户的需求。

- 便携式设计:我们的产品采用便携式设计,方便用户携带和使用,我们还提供多种配件和附件,以满足用户的不同需求。

- 优质售后服务:我们提供专业的技术支持和售后服务,帮助用户解决使用过程中遇到的问题,我们还定期对产品进行维护和升级,以保证产品的稳定性和可靠性。

随着纺织行业的不断发展,我们对纺织品测厚仪的需求也在不断增加,我们将继续研发和生产更高精度、更高性能的纺织品测厚仪,以满足客户的需求,我们还将不断优化产品性能和售后服务,提高客户满意度和忠诚度。

Articles related to the knowledge points of this article:

Top Textile and Home Furnishing Brands

The Evolution of Kung Fu-inspired Knives and Their Influence on Textile Design