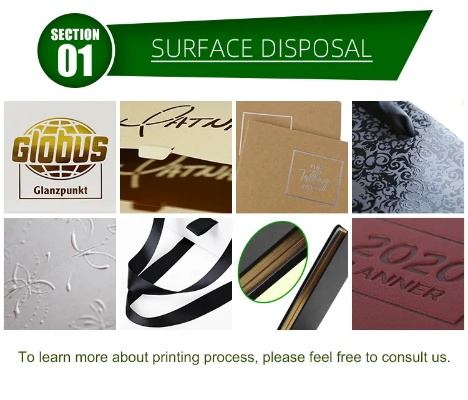

Comprehensive Guide to Textile Spot Printing Stamping Prices

This comprehensive guide provides a detailed overview of the prices for textile spot printing stamping services. The guide covers various aspects such as the cost of materials, labor, and equipment, as well as the pricing strategies used by different printing companies. It also includes information on how to negotiate prices and find the best deals for your specific needs.,The guide is designed to help businesses and individuals who need to produce high-quality printed products quickly and efficiently. Whether you are looking to create custom designs or simply need to update your existing product line, this guide can provide valuable insights into the costs associated with spot printing stamping services.,In addition to providing practical information, the guide also highlights some of the key factors that influence the final price of your print job. These include the complexity of your design, the size and weight of your product, and the level of detail required in your artwork. By understanding these factors, you can make informed decisions about which printing company to choose and what kind of services they offer.,Overall, this guide is an essential resource for anyone looking to get their textile products printed at competitive prices. With its comprehensive coverage of all aspects of spot printing stamping services, it provides a clear and concise overview of what to expect when it comes to pricing.

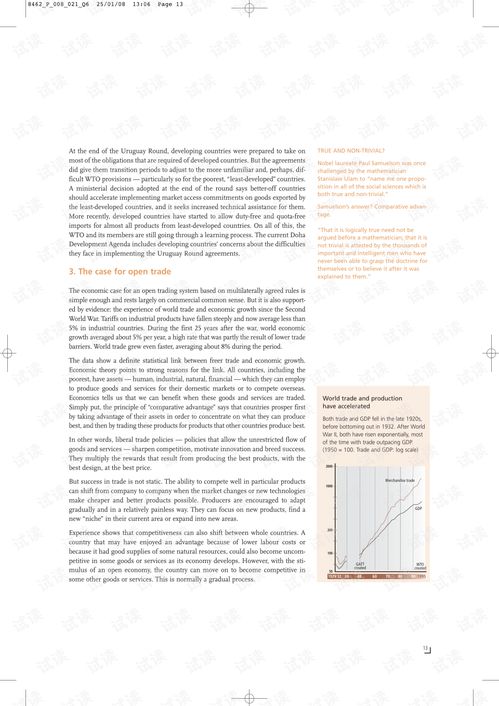

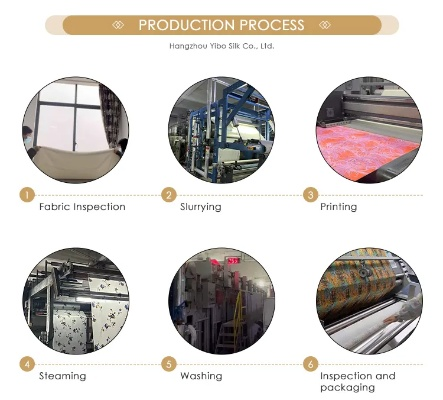

Introduction: In the world of textile manufacturing, spot printing is a crucial process that adds color and design to garments, accessories, and other textile products. The efficiency and accuracy of this technique rely heavily on the quality of the materials used, including the stamping tool—the stapling machine or stamper—and the adhesive used for the ink transfer. Among these essential components, the stapling tool is often referred to as the "stamping blade" or "stamping roller." Today, we'll delve into the world of textile stapler prices, covering everything from basic models to high-end options, along with some practical examples to illustrate how these tools can impact your bottom line.

Basic Stapler Prices: The cost of a stapler can vary significantly depending on its features and brand. Here's a simple table outlining the price range for different types of staplers:

| Type of Stapler | Price Range ($) |

|---|---|

| Basic Model | $150 - $300 |

| Midrange Model | $300 - $600 |

| High-End Model | $600 - $1,200 |

For example, a basic model stapler might have a single-layered roller, while a high-end model could feature a dual-layered roller with advanced coatings and precision control mechanisms.

Advanced Features: When it comes to choosing a stapler, consider features like speed, precision, durability, and ease of use. Some popular advanced features include:

- Speed Control: Allows you to adjust the speed of the stapler according to the type of material being printed.

- Precision Rollers: Enhanced rollers ensure even pressure and consistent results across different sizes and thicknesses of fabric.

- Durable Construction: Made from high-quality materials, ensuring longevity and reduced maintenance costs.

- Easy Cleaning: A convenient design that makes cleaning the stapler easy and quick.

High-End Example: Let's take a look at a high-end stapler model by StapleTech, priced at $800. This model features a dual-layer roller with anti-slip coatings and a built-in dust collector, providing superior performance and convenience. It also has a programmable speed control system that adjusts based on the type of fabric being processed, ensuring optimal results every time.

Cost-Effective Choices: If you're looking for a more economical option, consider purchasing a midrange stapler like the one shown in the table above. These staplers are generally less expensive but still offer good performance and reliability. For example, a midrange stapler priced at $400 could be a great choice if you need to handle a wide variety of textiles without breaking the bank.

Conclusion: When it comes to choosing a stapler for your textile printing business, there are many factors to consider. From basic models to high-end options, each has its own set of advantages and disadvantages. By understanding the key features and pricing points of different staplers, you can make an informed decision that aligns with your specific needs and budget. Remember, the right stapler can save you time, money, and ultimately, improve the quality of your textile products.

大家好,今天我们来探讨一下纺织品丝印胶刮的报价问题,丝印技术是纺织品生产中不可或缺的一部分,而胶刮作为丝印工艺中的关键辅助工具,其报价也备受关注,下面我们将从多个方面详细介绍纺织品丝印胶刮的报价情况。

纺织品丝印胶刮报价构成

- 材料成本:主要取决于丝印胶刮的材料选择,包括但不限于塑料、金属、玻璃纤维等,不同的材料价格差异较大,需要根据具体需求进行选择。

- 制作工艺成本:丝印胶刮的制作工艺包括设计、打样、生产等环节,每个环节的成本都会影响最终报价。

- 附加费用:可能包括运输费用、安装调试费用、售后服务费用等。

案例分析

以某纺织品公司为例,其丝印胶刮的报价情况如下:

- 材料成本:该公司选择使用高质量的塑料丝印胶刮,价格相对较高。

- 制作工艺成本:该公司在丝印胶刮的制作过程中采用了先进的生产工艺,确保产品质量和稳定性。

- 附加费用:该公司考虑到运输和安装调试的便捷性,选择了专业的物流公司进行运输,并由专业的安装团队进行安装调试。

报价策略建议

针对纺织品丝印胶刮的报价,以下是一些建议:

- 根据具体需求选择合适的材料和制作工艺,确保产品质量和稳定性。

- 在报价过程中充分考虑附加费用,如运输费用、安装调试费用等,确保客户得到合理的价格。

- 与供应商建立良好的合作关系,及时了解市场动态和价格变化,以获取更好的报价机会。

英文表格补充说明

以下是纺织品丝印胶刮报价的英文表格补充说明:

| 项目 | 单位 | 价格范围(美元/件) | 备注 |

|---|---|---|---|

| 材料成本 | 元/件 | 根据材料选择而定 | 包括但不限于塑料、金属、玻璃纤维等 |

| 制作工艺成本 | 元/件 | 根据制作工艺的复杂程度而定 | 包括设计、打样、生产等环节 |

| 附加费用 | 根据具体情况而定 | 如运输费用、安装调试费用等 | |

| 案例分析 | 根据具体公司情况而定 | 以某纺织品公司为例进行说明 |

纺织品丝印胶刮的报价是一个复杂的过程,需要考虑多个因素,在报价过程中,我们需要根据具体需求选择合适的材料和制作工艺,同时也要充分考虑附加费用,我们还需要与供应商建立良好的合作关系,及时了解市场动态和价格变化,以获取更好的报价机会,希望本文能够帮助大家更好地了解纺织品丝印胶刮的报价情况。

Articles related to the knowledge points of this article: