The Fabric of Our Future

The Fabric of Our Future: A Synthesis of Current and Future Technologies,In our rapidly evolving world, the fabric of our future is being woven with a combination of current technologies and emerging innovations. From artificial intelligence to renewable energy, these elements are intertwined in a complex web that promises to shape the course of human history. As we explore the possibilities of tomorrow, it is essential to recognize the challenges and opportunities that lie ahead.,One of the most significant drivers of change is the rise of automation and artificial intelligence. These technologies are already transforming industries across the board, from manufacturing to healthcare to finance. They offer unprecedented levels of efficiency and accuracy, but also raise questions about job displacement and ethical considerations.,At the same time, there is a growing recognition of the importance of sustainability and environmental stewardship. This has led to a renewed focus on renewable energy sources such as wind and solar power, which promise to mitigate the impacts of climate change while providing reliable energy supplies for generations to come.,As we move forward into an uncertain future, it is crucial that we approach this challenge with a balanced and thoughtful approach. By embracing the best of both worlds—the potential of technology and the wisdom of tradition—we can build a brighter, more sustainable future for all.

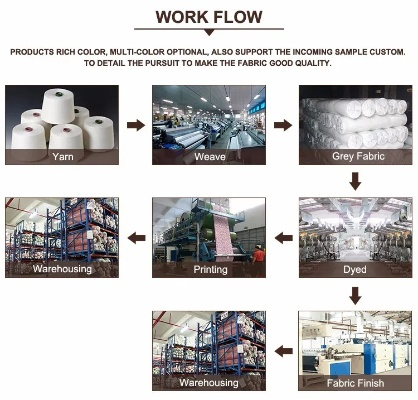

In the vast and intricate world of textile manufacturing, there are countless tasks that go into creating the clothes, materials, and accessories we wear every day. From the raw materials to the finished product, the process is a meticulous blend of science, art, and human ingenuity. Today, I'll take you on a journey through the fabrication of one such essential component: the textile fibers themselves. Let's dive into the lifecycle of a single cotton thread from its origins to the finished garment.

Cotton: A Classical Textile Fiber

Cotton, known for its softness and breathability, is one of the most widely produced textile fibers globally. It's derived from the seeds of the cotton plant (Gossypium spp.), which thrives in tropical climates. The process of producing cotton involves several stages:

-

Planting: Cotton plants are grown in fields across the globe, primarily in Asia, Africa, and South America. They require ample sunlight, fertile soil, and regular watering to thrive.

-

Harvesting: After a growing season, the cotton bolls (clusters of seeds) are harvested manually or with mechanical tools. Harvesting techniques vary depending on the region and the specific type of cotton being grown.

-

Pre-treatment: Before spinning, the cotton is subjected to various pre-treatment processes, including washing, deseeding, and bleaching, to remove impurities and enhance color.

-

Spinning: The cleaned cotton is then spun into yarn using a process called "carding." This involves passing the cotton through rollers to break it down into long, thin strands. These strands are then twisted together to form a continuous yarn.

-

Weaving: Yarn production is followed by weaving, where threads are woven together to form fabric. There are various types of weaving, including plain weave, twill weave, and knit weave, each with their own unique texture and pattern.

-

Finishing: Once the fabric is woven, it undergoes further processing to enhance its appearance and functionality. This may include dyeing, printing, embroidery, and finishing treatments like coating or finishing.

-

Packaging: Finally, the finished textile products are packaged and shipped to retailers or end consumers worldwide.

Now, let's turn our attention to another crucial element in this textile journey: Wool. Wool, another classic fiber, is made up of long, curly fibers that have a distinctive crimped appearance. Here's how wool comes to life:

Wool: The Warmth of the World

Wool is a natural fiber that comes from sheep's wool or other animals' hair. The process of turning wool into yarn involves several stages:

-

Feeding: Sheep are fed a diet rich in protein and minerals, ensuring they grow strong and healthy wool.

-

Shearing: Sheep are sheared to remove excess hair and create new wool fibers. This process can be done manually or using machinery.

-

Carding: The wool is carded to separate the individual fibers and prepare them for spinning. This step is crucial for producing high-quality yarn.

-

Spinning: The carded wool is spun into yarn using a process called "combing." This involves passing the wool through a series of rollers to twist the fibers together.

-

Weaving: Yarn production is followed by weaving, where threads are woven together to form fabric. Wool weaving can be done on a loom or by hand, depending on the desired pattern and thickness of the fabric.

-

Finishing: Once the fabric is woven, it undergoes further processing to enhance its appearance and functionality. This may include dying, printing, embroidery, and finishing treatments like coating or finishing.

-

Packaging: Finally, the finished woolen products are packaged and shipped to retailers or end consumers worldwide.

These two examples highlight just a fraction of the complexities involved in the textile industry. Each step of the process from planting to packaging is interconnected, with feedback loops that ensure quality control and sustainability throughout the entire lifecycle.

From the humble beginnings of cotton and wool to the cutting-edge innovations in synthetic fibers and eco-friendly materials, the textile industry continues to evolve and adapt to meet the changing needs and demands of our global society. As we move forward into an era of sustainability and environmental consciousness, the textile industry will undoubtedly face new challenges and opportunities, but it remains committed to producing high-quality, ethically sourced, and sustainable textiles that make a positive impact on both people and the planet.

The Daily Routines of a Textile Factory

纺织厂的主要工作内容概述

纺织厂是制造各种纺织品的重要工厂,其主要工作涵盖从原材料收集、生产准备、织造、染整到成品检验等多个环节,以下是对纺织厂主要工作内容的大致介绍:

原材料收集与准备

纺织厂首先从各种原材料供应商处采购高质量的纤维和纱线,然后进行必要的清洗和整理,确保原材料的质量和适应性。

织造工序

在织造工序中,纺织厂使用先进的织造设备和技术,将纤维编织成各种纺织品,这个过程包括选择合适的织物类型、设计图案和尺寸,然后进行织造。

染整加工

染整加工是纺织过程中的重要环节,包括染色和整理,纺织厂使用专业的染料和整理剂,对纺织品进行染色和整理,使其具有特定的颜色、质地和外观。

成品检验与包装

在完成织造和染整加工后,纺织厂会对成品进行严格的检验,确保产品质量符合标准,然后进行包装,将成品运送到销售市场或客户手中。

案例说明:纺织厂的日常工作流程

以下是一个具体的纺织厂日常工作流程的案例说明:

案例:某大型纺织厂的日常运作

某大型纺织厂在日常工作中主要涉及以下几个环节:原材料采购、生产计划制定、织造生产、染整加工以及成品检验与包装,以下是对该案例的详细说明:

原材料采购与准备

该纺织厂从多个供应商处采购高质量的纤维和纱线,经过严格的清洗和整理后,确保原材料的质量和适应性,该厂会根据市场需求和生产计划制定合理的生产计划,确保原材料的供应。

生产计划制定与执行

该纺织厂会根据市场需求和生产条件制定详细的生产计划,然后按照计划进行生产,在生产过程中,该厂会密切关注生产进度和质量,确保生产过程的顺利进行,该厂还会定期对生产过程进行评估和改进,提高生产效率和产品质量。

织造工序

在该纺织厂的织造工序中,首先使用先进的织造设备和技术将纤维编织成各种纺织品,该厂会根据设计图案和尺寸选择合适的织物类型,然后进行精细的织造,该厂还会注重环保和节能技术的应用,提高生产效率和环保水平。

染整加工与成品检验

在该纺织厂的染整加工环节中,使用专业的染料和整理剂对纺织品进行染色和整理,该厂会对成品进行严格的检验,确保产品质量符合标准,该厂还会定期对染整工艺进行优化和改进,提高染整工艺的效率和产品质量,该厂会将成品包装好并运送到销售市场或客户手中。

补充说明:纺织厂的设备和工艺技术

在纺织厂的设备和工艺技术方面,该厂主要采用了先进的织造设备和技术,包括高速织布机、自动染色机等,该厂还注重环保和节能技术的应用,采用环保染料和节能工艺技术,提高生产效率和环保水平,该厂还注重产品质量和客户需求的满足,不断提高生产工艺和技术水平。

纺织厂是制造纺织品的重要工厂,其主要工作涵盖从原材料收集、生产准备、织造、染整到成品检验等多个环节,在纺织厂的日常工作流程中,注重原材料的质量和适应性、生产计划的制定和执行、织造工序的精细化和环保技术的应用等都是非常重要的环节,纺织厂还需要不断更新设备和工艺技术,提高生产效率和产品质量。

Articles related to the knowledge points of this article:

Navigating the Global Market with Xian Textile Factory Processing

A Glimpse into the Wonders of a Traditional Textile Factory

The Echoes of Threads:A Journey Through the Sounds of a Textile Mill