The Science Behind Textile Glue Sprayers

Textile glue sprayers are a crucial tool for the textile industry, enabling efficient and precise application of adhesives to fabrics. The science behind these devices involves the principles of physics, chemistry, and engineering. Firstly, the aerodynamic design of the sprayer ensures that the glue is evenly distributed across the fabric surface, with minimal wastage. The use of high-pressure air compressors powers the sprayer, propelling the glue through a nozzle and onto the fabric. The chemistry of the glue itself plays a significant role in its performance. The glue must be formulated with specific properties, such as adhesion strength, flexibility, and durability, to ensure optimal bonding with the fabric. Additionally, the chemical reactions between the glue and fabric material determine how well the glue adheres to the fabric. Finally, the engineering aspects of the glue sprayer involve ensuring that the device is reliable, easy to use, and maintainable. This includes factors such as ease of cleaning, durability, and compatibility with different types of fabrics. Overall, the science behind textile glue sprayers is complex but essential for the success of the textile industry.

Introduction: Textile glue sprayers are essential tools in the world of textile manufacturing, providing a secure and reliable bond between fabrics. They are used to apply adhesive or coatings onto various materials, including cotton, polyester, and even metallic threads, for the purpose of finishing, reinforcement, or aesthetic enhancement. In this article, we will delve into the science behind these machines, their working principles, and how they contribute to the success of modern textile production.

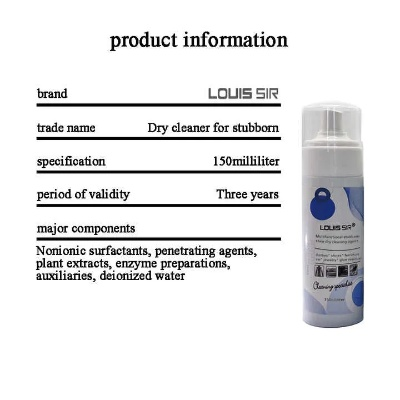

Working Principles: Textile glue sprayers operate on the principle of pressure, temperature, and chemical reaction. These machines typically consist of a reservoir containing the glue, a pump that delivers the glue at high pressure through a nozzle, and a heating element that raises the temperature of the glue to facilitate its application. When the glue is sprayed onto the fabric, it undergoes a chemical reaction with the fibers, creating a strong bond that resists wear and tear.

Thermal Energy: One of the key components of any glue sprayer is the heating element. This element converts electrical energy into heat, which is then transferred to the glue via a condenser coil. As the heat is transferred, the glue begins to melt and flow more easily. This process is crucial for ensuring that the glue adheres to the fabric evenly and securely.

Pressure Control: Another critical aspect of glue sprayers is the pressure control system. This system regulates the amount of pressure exerted on the glue by the pump. High pressure ensures that the glue penetrates deep into the fabric fibers, while low pressure allows for a more controlled application. This balance between pressure and temperature is vital for achieving optimal results.

Chemical Reaction: The glue itself plays a significant role in the bond-forming process. It is a polymer compound that reacts with the fibers of the fabric when exposed to heat and pressure. This chemical reaction creates a strong bond between the glue and the fabric, making it resistant to wear and tear.

Application: Once the glue has been applied to the fabric, it needs to be cured before it becomes fully effective. Curing involves increasing the temperature of the glue and applying pressure to ensure that all areas are properly bonded. This process takes place in a curing chamber or oven, where the glue is exposed to high temperatures and pressure for a specific period of time.

Case Study: One example of a successful textile glue application can be seen in the manufacture of high-end sportswear. A company that specializes in producing custom-fitted athletic apparel uses a specialized glue sprayer to apply a waterproof and breathable coating to their fabrics. By using a combination of thermal energy and pressure control, the company was able to achieve a uniform and strong bond between the fabric and the coating, resulting in superior performance and durability.

Conclusion: Textile glue sprayers are a vital tool in the world of textile manufacturing, providing a reliable and efficient way to apply adhesives and coatings to fabrics. By understanding the science behind these machines and how they work, manufacturers can optimize their processes and create high-quality products that meet the demands of today's market. With the right equipment and knowledge, anyone can become an expert in the art of textile glue application.

今天我们将探讨纺织品喷胶机的原理及其在实际应用中的重要性,喷胶机是一种用于添加胶水到纺织品上的设备,它通过高压喷射胶水来实现对纺织品的固定和装饰效果,本文将通过图表和案例分析来详细阐述喷胶机的原理和工作过程。

纺织品喷胶机原理

纺织品喷胶机主要由喷胶头、喷胶泵、控制系统等部分组成,喷胶头是喷胶机的核心部件,它通过高压喷射胶水,将胶水均匀地涂抹在纺织品表面,喷胶泵则是提供高压喷射的装置,其工作原理是通过电机驱动,将液体转化为高压喷射状态,控制系统则负责调节喷胶机的各项参数,如喷胶压力、喷胶速度等,以确保喷胶效果符合要求。

喷胶头工作原理

喷胶头通过高压喷射胶水,将胶水均匀地涂抹在纺织品表面,在喷涂过程中,喷胶头内部装有特殊的喷嘴和喷嘴调节装置,可以根据纺织品表面的纹理和形状进行精确控制,喷胶头还配备了温度传感器和压力传感器,可以实时监测胶水的温度和压力,确保喷涂效果符合要求。

控制系统工作原理

控制系统是纺织品喷胶机的核心部件之一,它负责调节喷胶机的各项参数,如喷胶压力、喷胶速度等,控制系统通常由微处理器、传感器和执行器等组成,微处理器是控制系统的核心部件,它负责接收传感器传递的信号,并根据信号调节喷胶机的各项参数,传感器可以实时监测纺织品表面的温度、湿度、压力等参数,以确保喷涂效果符合要求,执行器则负责根据控制系统的指令,控制喷胶泵的工作状态,从而实现对纺织品表面的固定和装饰效果。

案例分析

以某纺织品生产企业为例,介绍纺织品喷胶机的实际应用情况,该企业使用了一种新型的纺织品喷胶机,该设备采用了先进的喷胶技术,能够实现对纺织品的高效固定和装饰效果。

设备介绍

该新型纺织品喷胶机采用了先进的喷胶技术,具有高精度、高效率、低噪音等优点,它采用了高压喷射的方式,能够将胶水均匀地涂抹在纺织品表面,实现快速固化,该设备还配备了智能控制系统,可以根据纺织品表面的纹理和形状进行精确控制,提高了喷涂效果和质量。

应用场景

该纺织品喷胶机在实际应用中具有广泛的应用场景,它可以应用于各种类型的纺织品生产中,如丝绸、棉布、麻布等,在纺织品的加工过程中,该设备可以实现对纺织品的快速固定和装饰效果,提高了生产效率和质量,该设备还可以应用于服装、家居用品等领域,为消费者提供更加美观、舒适的穿着体验和家居装饰效果。

纺织品喷胶机是一种重要的纺织机械设备,它能够实现对纺织品的固定和装饰效果,本文通过图表和案例分析,介绍了纺织品喷胶机的原理和工作过程,在实际应用中,纺织品喷胶机具有广泛的应用场景,可以应用于各种类型的纺织品生产中,为消费者提供更加美观、舒适的穿着体验和家居装饰效果,随着科技的不断进步,纺织品喷胶机的性能和功能也将不断提高,为纺织行业的发展带来更多的机遇和挑战。

Articles related to the knowledge points of this article:

The Recycling Journey of a Little Friend

Exploring the World of Textiles:A Glossary of Different Fabric Materials

The Price Dynamics of Nano Silver Textiles:A Comprehensive Analysis