The Textile Bleaching Process:A Comprehensive Guide

This comprehensive guide provides a detailed overview of the textile bleaching process, highlighting its importance in the textile industry. The process involves the use of chemicals to remove any colorants from fabrics, leaving them whiter and more uniform. The guide covers the different types of bleaching agents available, including chlorine-based and oxygen-based bleaches, as well as their applications and benefits. It also explains the various stages of the bleaching process, from pretreatment to post-treatment, and discusses the challenges faced by manufacturers when implementing this process. Finally, the guide provides tips and best practices for ensuring successful results, including proper equipment maintenance and operator training. Overall, this guide provides essential information for anyone involved in the textile bleaching process, helping them achieve optimal results while minimizing risks and costs.

Introduction: The textile industry is a crucial sector that contributes significantly to global economic growth. One of the critical steps in the production process is the bleaching of textiles, which involves the removal of unwanted colorants and impurities from fabrics to achieve a desired shade. This article will provide an overview of the bleaching process, including its various stages, equipment requirements, and case studies highlighting successful applications.

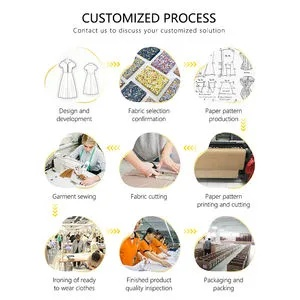

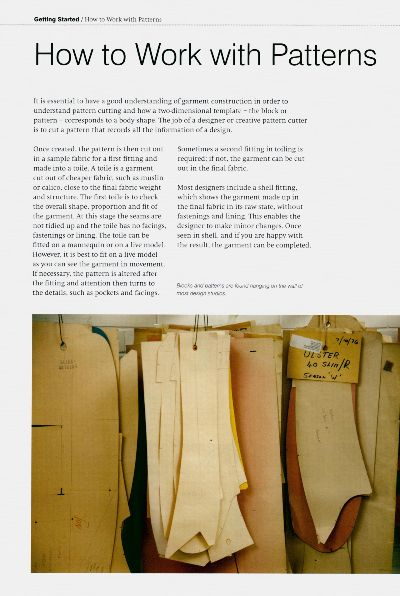

Stage 1: Raw Material Preparation Before starting the bleaching process, it is essential to prepare the raw materials such as cotton, wool, silk, or other natural fibers. The quality of these raw materials directly affects the outcome of the bleaching process. For instance, high-quality raw materials can withstand the harsh conditions of the bleaching process without losing their strength or color.

Stage 2: Chemical Pretreatment Chemical pretreatment is the first step in the bleaching process. It involves treating the raw materials with chemicals such as sodium hypochlorite (NaOCl) or hydrogen peroxide to remove any existing colorants or stains. This stage also helps to break down any insoluble compounds that may hinder the bleaching process.

Stage 3: Bleaching Once the chemical pretreatment has been completed, the fabric undergoes actual bleaching using a solution of sodium hypochlorite or hydrogen peroxide. The concentration and temperature of the bleaching solution play a significant role in determining the effectiveness of the process. High concentrations and temperatures can cause damage to the fabric's structure and color, while lower concentrations and gentler conditions can lead to better results.

Stage 4: Post-Bleaching Treatments After the fabric has been bleached, it undergoes post-bleaching treatments to enhance its appearance and durability. These treatments may include dyeing, printing, or finishing processes, depending on the desired outcome. Additionally, the fabric may be washed to remove any remaining chemicals or residual bleaching agents.

Equipment Requirements: The bleaching process requires specialized equipment such as bleach tanks, washing machines, dryers, and dyeing machines. Each stage of the process requires different types of equipment to ensure optimal results. For example, the bleach tank must be designed to handle high concentrations of chemicals and maintain consistent temperature levels. Similarly, the washing machine should have advanced technology to remove any remaining bleaching agents effectively.

Case Study: One successful application of the bleaching process can be seen in the manufacture of athletic wear. In this case, the fabric undergoes a chemical pretreatment followed by a series of bleaching and post-bleaching treatments. The final product is lightweight, durable, and highly visible, making it ideal for sportswear.

Conclusion: The textile bleaching process is a complex but necessary step in the production process. By understanding the various stages and equipment requirements, manufacturers can produce high-quality textiles that meet consumer demands. Case studies highlight successful applications of the bleaching process, demonstrating its potential for innovation and improvement.

纺织品漂白工艺流程概述

纺织品漂白工艺是一个复杂的过程,主要包括以下几个步骤:准备原料、漂白剂使用、漂白处理、干燥和成品检验,下面我们将详细介绍这个工艺流程。

原料准备

在开始漂白之前,首先需要准备好所需的原料,包括各种纺织纤维、漂白剂等,这些原料需要符合相关标准和安全要求。

漂白剂使用

使用适当的漂白剂是漂白工艺的关键步骤,漂白剂的作用是去除纺织品表面的色素和污渍,使其恢复原有的颜色和光泽,在漂白过程中,需要严格控制漂白剂的浓度、温度和时间等参数,以确保漂白效果和安全性。

漂白处理

在漂白过程中,需要对纺织品进行一系列的处理,包括预处理、漂洗、干燥等步骤,预处理是为了去除纺织品表面的杂质和污渍,为后续的漂白处理做好准备,漂洗是将纺织品放入漂白液中进行清洗,去除多余的漂白剂和杂质,干燥则是将清洗后的纺织品进行最后的处理,使其达到所需的干燥程度。

工艺流程图表说明

以下是纺织品漂白工艺流程的图表说明:

(请在此处插入图表)

案例说明

以一个具体的纺织品漂白案例为例,进一步说明这个工艺流程。

案例:某品牌棉质衣物漂白

该品牌有一批棉质衣物需要进行漂白处理,准备好所需的原料,包括棉质纤维、漂白剂等,按照正确的工艺流程进行漂白处理,在漂洗过程中,需要严格控制漂白液的浓度和温度,确保漂白效果和安全性,经过干燥处理后,得到符合要求的纺织品。

补充说明(表格)

以下是纺织品漂白工艺流程的补充说明表格:

| 步骤 | 描述 | 具体操作 | 注意事项 |

|---|---|---|---|

| 原料准备 | 选择合适的纺织纤维和漂白剂 | 根据需求选择原料,确保符合相关标准和安全要求 | 确保原料质量符合要求 |

| 漂白剂使用 | 使用适当的漂白剂浓度和温度 | 根据衣物材质和颜色选择合适的漂白剂浓度和温度 | 控制漂白剂使用量,避免过度漂白 |

| 预处理 | 清洗衣物表面杂质和污渍 | 对衣物进行清洗处理,去除表面的杂质和污渍 | 注意清洗方式,避免损伤衣物纤维 |

| 漂洗 | 将衣物放入漂白液中进行清洗 | 将清洗后的衣物放入漂白液中清洗,去除多余的漂白剂和杂质 | 控制漂洗时间,避免过度漂白 |

| 干燥处理 | 进行最后的干燥处理 | 将清洗后的衣物进行干燥处理,达到所需的干燥程度 | 注意干燥温度和时间,避免过度干燥或不足干燥 |

| 检验与包装 | 进行质量检验和包装 | 对最终产品进行质量检验和包装,符合相关标准和安全要求 | 注意检验标准和方法,确保产品质量合格 |

纺织品漂白工艺是一个复杂而关键的过程,需要严格控制各个步骤和参数,通过正确的工艺流程和注意事项,可以确保纺织品达到理想的颜色和光泽效果,同时保证产品的安全性和质量。

Articles related to the knowledge points of this article:

An Overview of Textile-Based Mobile Phone Cases

The Ultimate Guide to Textile Advertising Strategies

The Unique Sites of the Special Needlework Textiles Wholesale Market in Suzhou