Exploring the Rich Tapestry of Textile Composites:An Overview

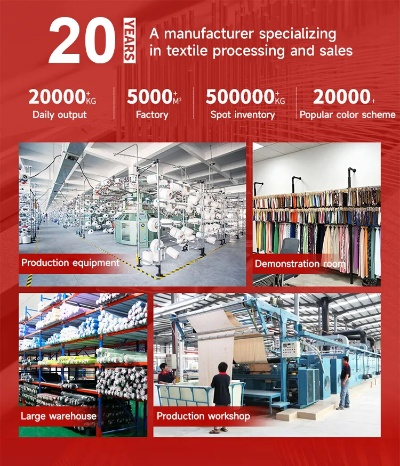

Textile composites, a diverse and complex category of materials, have been the subject of extensive research in recent years. These composites combine the strength and durability of natural fibers with the flexibility and aesthetic appeal of synthetic polymers. The study of textile composites is important for several reasons. Firstly, they offer a range of applications in various industries, including construction, automotive, and aerospace. Secondly, their unique properties make them ideal for use in high-performance environments where durability and longevity are critical factors. Additionally, the development of new materials and techniques can lead to significant advancements in the field of composites, which could have far-reaching implications for society as a whole. Overall, the exploration of textile composites is an essential area of research that holds promise for the future of materials science and engineering.

Introduction: Textiles, an integral part of human civilization, have evolved from simple weaves to sophisticated composite materials. The fabrication of these textiles involves a plethora of processes that not only enhance their functionality but also add beauty and durability to them. In this article, we delve into some of the most innovative textile composite techniques, including their applications, benefits, and case studies.

- Embroidery and Embroidered Fabrics

- Lamination and Laminated Fabrics

- Stitch-bonding and Stitched Fabrics

- Heat-seaming and Heat-seamed Fabrics

- Embroidered and Embroidered Threads

- Embroidered Threads and Embroidered Fabrics

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Threads

- Embroidered Threads and Embroidered Title: The Art of Weaving: A Journey Through Textile Composites

Introduction: Weaving is one of the oldest known textile techniques, with its roots stretching back thousands of years in various cultures around the world. Today, however, weaving has evolved into a sophisticated art form, where it's not just about creating functional textiles but also incorporating advanced composite materials to enhance their properties. In this article, we explore the different types of textile composite techniques, their applications, benefits, and highlight some real-life examples to give you a glimpse into how these techniques are transforming the world of textiles.

-

Embroidery: This technique involves stitching tiny beads or threads onto a fabric surface to create intricate patterns or designs. While traditionally used for decorative purposes, it can now be applied to composite materials like woven or knitted fabrics to enhance their aesthetic appeal or provide structural support. For example, in sportswear, the use of high-density polyester thread embedded with metallic beads creates a durable yet stylish finish.

-

Lamination: This process involves layering two or more layers of fabric together with adhesive or other adhesives between them to reinforce them against wear and tear. It's commonly used in protective clothing, such as firefighters' uniforms, which are made from layers of fireproof material sandwiched between layers of cotton or polyester for comfort and breathability.

-

Stitch-bonding: This method involves stitching together multiple layers of fabric to strengthen them against external forces like wind or water pressure. It's particularly useful in designing boats or other structures that need to withstand harsh conditions. For instance, the sails on a sailing boat are often stitch-bonded to increase their strength and durability.

-

Heat-seaming: This technique involves heating up the edges of two pieces of fabric together to fuse them together, creating a stronger bond than traditional stitching methods. It's commonly used in manufacturing garments like jackets, where the seams are heat-seamed to ensure they stay intact over time.

-

Embroidering and Embroidered Threads: This technique involves using small beads or threads to create detailed patterns on fabric surfaces. While traditionally used for decorative purposes, it can now be applied to composite materials like woven or knitted fabrics to enhance their aesthetic appeal or provide structural support. For example, in sportswear, the use of high-density polyester thread embedded with metallic beads creates a durable yet stylish finish.

-

**Embroidered Threads and Embroidered

纺织品作为日常生活中不可或缺的材质,其制作工艺多种多样,随着科技的进步和人们对美观、舒适度的追求,复合工艺在纺织品制作领域的应用越来越广泛,本文将探讨纺织品中的复合工艺,并通过英文案例说明来进一步阐述其特点和应用。

纺织品复合工艺概述

复合工艺定义

纺织品复合工艺是一种将多种工艺技术融合在一起,通过特定的工艺流程和材料组合,制作出具有独特性能和美观效果的纺织品。

复合工艺类型

复合工艺主要包括织造、染整、印花、绣花等工艺,织造工艺是最为基础的工艺,通过编织、织造等方式将各种材料组合在一起;染整工艺则是对纺织品进行颜色、质地等方面的处理,使其具有更好的外观和性能;印花和绣花工艺则是根据需要,在纺织品上添加图案或图案装饰。

复合工艺案例分析

织物增强复合工艺

织物增强复合工艺是一种通过添加纤维增强材料,提高织物强度和耐久性的工艺,使用玻璃纤维增强聚酯纤维织物,不仅提高了织物的强度和耐久性,还提高了纺织品的外观和手感,这种工艺在户外用品、运动装备等领域有着广泛的应用。

功能性纺织品复合工艺

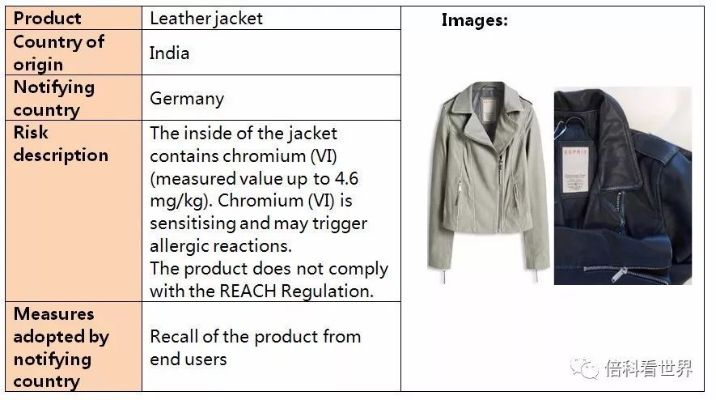

功能性纺织品复合工艺是一种通过添加特殊功能材料,提高纺织品在特定领域应用的性能的工艺,抗菌纺织品通过添加抗菌剂和纤维材料,具有抗菌、防霉等特殊功能,适用于医疗、卫生等领域,防水、透气等特殊性能的纺织品也得到了广泛应用。

纺织品复合工艺的具体应用

织物编织与印染技术结合

织物编织与印染技术结合是一种将编织技术和印染技术相结合,制作出具有独特纹理和外观的纺织品,通过编织技术制作出具有凹凸纹理的服装面料,再通过印染技术赋予其颜色和图案,这种工艺可以制作出具有高强度、高舒适度的服装面料。

环保材料的应用

随着环保意识的提高,越来越多的纺织品开始使用环保材料,使用可降解材料制作环保纺织品,不仅可以减少环境污染,还可以提高纺织品的环保性能,这种工艺可以制作出更加环保、健康的纺织品。

复合工艺的发展趋势

随着科技的进步和人们对纺织品品质、美观、舒适度的追求不断提高,纺织品复合工艺将会越来越受到重视和发展,复合工艺将会更加注重材料的创新、工艺的优化和产品的个性化定制,复合工艺也将更加注重环保、健康等方面的要求,推动纺织品的可持续发展。

纺织品复合工艺是一种将多种工艺技术融合在一起,制作出具有独特性能和美观效果的纺织品的工艺方法,随着科技的进步和人们对纺织品品质、美观、舒适度的追求不断提高,复合工艺将会得到更加广泛的应用和发展,复合工艺也将推动纺织品的可持续发展,为人们的生活带来更多的便利和舒适。

Articles related to the knowledge points of this article:

The Evolution of Haimen Newborn Textile Factory

Tu Yundang Textiles:A Reflection on the Journey of Quality and Innovation