The Environmentally Friendly Alternatives to Chemical Dyes in Textiles

In recent years, the use of chemical dyes in textiles has been widely criticized due to their negative impact on the environment. This paper proposes an alternative approach to chemical dyeing, which involves using environmentally friendly alternatives such as natural dyes and biodegradable polymers. These alternatives are not only more sustainable but also offer better colorfastness and washability than traditional chemical dyes. In addition, they can be produced from renewable resources and have a lower carbon footprint compared to synthetic chemicals. However, there are still challenges associated with the production and application of these alternatives, such as high costs and limited availability. Despite these limitations, the development of these alternatives is essential for reducing the environmental impact of textile production and promoting sustainable practices.

Introduction: The textile industry is one of the most polluting industries globally, with a significant portion of its dyes derived from harmful chemicals. These dyes not only pose a threat to human health but also contribute to environmental pollution. As a result, there has been a growing demand for eco-friendly alternatives to chemical dyes in textiles. In this article, we will explore some of the latest advancements in the field of textile printing and discuss how these eco-friendly alternatives can help reduce the carbon footprint of the industry.

Eco-Friendly Alternatives to Chemical Dyes in Textiles:

-

Recycled Dyes

- Benefits: Recycled dyes are derived from waste materials such as cotton, wool, and silk. They are biodegradable and non-toxic, making them an excellent alternative to traditional chemical dyes.

- Case Study: A company in the USA developed a process that uses recycled dyes to print organic cotton fabrics. The resulting products have a high level of color intensity and durability.

-

Natural Dyes

- Benefits: Natural dyes are derived from plants, animals, or minerals and do not contain harmful chemicals. They are also renewable and sustainable.

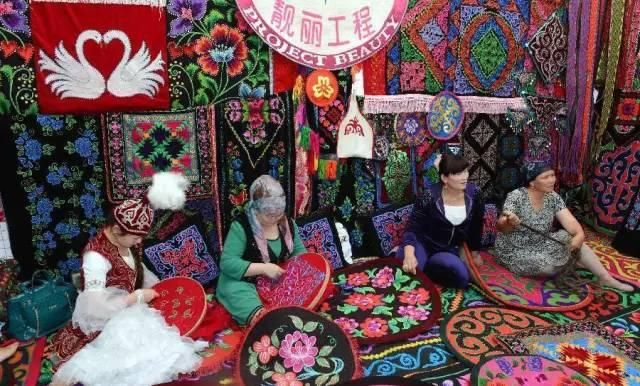

- Case Study: A brand in India developed a line of natural dyed clothes using plant extracts like turmeric and neem. These products were sold at a premium price due to their unique color and texture.

-

Bio-based Dyes

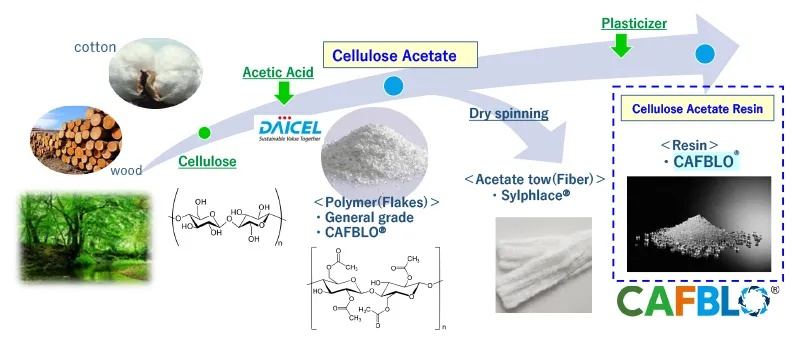

- Benefits: Bio-based dyes are derived from renewable resources like wood pulp or sugarcane. They are biodegradable and do not produce harmful byproducts.

- Case Study: A company in China developed a bio-based dyeing process for cotton fabrics. The resulting products had a brighter color and higher durability than traditional chemical dyes.

-

Oil-Free Dyes

- Benefits: Oil-free dyes are derived from plant oils or other natural sources and do not contain any petroleum-based solvents. They are also biodegradable and non-toxic.

- Case Study: A brand in Europe developed a line of eco-friendly clothing using oil-free dyes. The products were sold at a premium price due to their unique color and texture.

-

Water-Soluble Dyes

- Benefits: Water-soluble dyes are designed to dissolve easily in water and require less water for printing. This reduces the amount of water used in the production process and helps conserve water resources.

- Case Study: A company in the USA developed a water-soluble dyeing process for denim fabrics. The resulting products had a vibrant color and high durability.

Conclusion: The textile industry has a significant role to play in reducing its environmental impact. By adopting eco-friendly alternatives to chemical dyes, companies can create products that are both sustainable and attractive to consumers. The use of recycled, natural, bio-based, oil-free, and water-soluble dyes is just the beginning of the journey towards a greener future for the textile industry. As technology continues to advance, we can expect even more innovative solutions to emerge, paving the way for a more sustainable and responsible industry.

纺织品环保浆料概述

随着环保意识的日益增强,纺织品行业也在寻求更为环保的生产方式,纺织品环保浆料作为一种新型材料,在纺织品的生产过程中发挥着重要作用,它不仅可以提高纺织品的环保性能,还能有效降低生产成本,提高生产效率。

纺织品环保浆料的主要特点

- 环保性:采用可回收、无污染的原料制作,减少对环境的污染。

- 高性能:具有优异的粘合性能、耐磨性、抗皱性等,满足纺织品的特殊要求。

- 成本效益:相较于传统材料,纺织品环保浆料具有较低的生产成本和较高的使用价值。

纺织品环保浆料的应用案例

某大型纺织企业采用纺织品环保浆料生产高档面料,该企业通过优化生产工艺,使用纺织品环保浆料替代部分传统材料,不仅提高了产品质量,还降低了生产成本,该企业还积极推广绿色生产理念,鼓励员工参与环保活动,取得了良好的社会效益。

某地区政府为了推动绿色纺织产业发展,鼓励当地企业使用纺织品环保浆料生产绿色纺织品,该地区政府通过提供政策支持、技术支持和宣传推广等措施,帮助当地企业实现绿色生产,该地区政府还积极推动循环经济和绿色消费,提高了当地纺织品的环保性能和市场竞争力。

纺织品环保浆料的生产工艺及技术

- 原料选择:选择可回收、无污染的原料制作浆料,确保产品质量和环保性能。

- 生产工艺:采用先进的生产工艺,包括原料预处理、混合、干燥、成型等步骤。

- 检测标准:制定严格的检测标准,确保浆料的质量和环保性能符合要求。

纺织品环保浆料的市场前景及发展趋势

随着人们对环境保护意识的不断提高,纺织品环保浆料的市场前景越来越广阔,纺织品环保浆料将朝着更加环保、高效、智能化的方向发展,随着技术的不断进步,纺织品环保浆料的生产成本将进一步降低,应用范围将进一步扩大。

纺织品环保浆料作为一种新型材料,在纺织品的生产过程中发挥着重要作用,它不仅可以提高纺织品的环保性能,还能有效降低生产成本,提高生产效率,随着人们对环境保护意识的不断提高,纺织品环保浆料的市场前景越来越广阔,纺织品环保浆料将朝着更加环保、高效、智能化的方向发展,为了实现可持续发展,我们应该积极推广纺织品环保浆料的应用,推动绿色生产理念的发展。

Articles related to the knowledge points of this article:

Quality in Knitwear:A Comprehensive Guide to Assessing and Understanding