Understanding the Science Behind Textile Water Repellency Tests

: Exploring the Science Behind Textile Water Repellency Tests,Abstract:,Textile water repellency is a crucial property that determines how well a fabric resists wetting by water. This paper aims to elucidate the scientific principles behind textile water repellency tests, which are essential for understanding and improving the performance of various textile products. The study discusses the different methods used in testing water repellency, including the WGTT (Wettability Gradient Time) method, which measures the rate at which a material loses its water-repellent properties over time. The paper also examines the role of surface morphology, such as hydrophobicity and roughness, in determining water repellency. Additionally, it explores the correlation between textile properties and water repellency, highlighting the importance of understanding these relationships for designing effective water-resistant textiles. Overall, this study provides a comprehensive understanding of the science behind textile water repellency tests, offering insights into the factors that influence the performance of textiles in practical applications.

Water repellency, or hydrophobicity, is a crucial property in the design and application of textile materials. It refers to the ability of a material to resist wetting by water, which is essential for many industrial applications such as sportswear, automotive interiors, and outdoor gear. In this discussion, we will delve into the principles behind textile surface water repellency tests, explore practical examples, and discuss how these tests are performed.

Textile surface water repellency is influenced by a variety of factors, including the chemical composition of the fibers, the structure of the fabric, and the finishing treatments applied during manufacturing. The hydrophobic properties of these materials can be enhanced through various methods such as coating with wax or silicone, or through the use of specialized finishes that mimic the natural hydrophobicity of certain plant species.

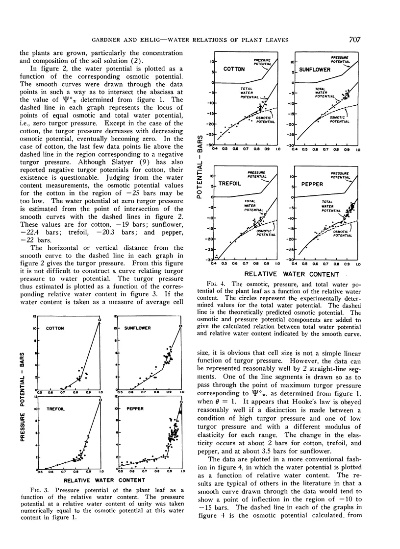

To test the water-repellent properties of textiles, several laboratory methods exist. One common method involves using a droplet of water on the textile surface and observing its behavior. If the water does not spread or roll off the surface, it indicates good water repellency. A more quantitative approach involves measuring the contact angle between a water droplet and a textile surface. A high contact angle indicates good hydrophobicity, while a low contact angle suggests poor resistance to water.

One of the most widely used testing methods is the ASTM D1238 standard, which provides guidelines for conducting water repellency tests on textiles. This standard includes both static and dynamic tests, allowing for a comprehensive assessment of the material's performance under different conditions. For example, in a static test, a droplet of water is placed on the textile surface and allowed to stand still for a specified period before being observed. In a dynamic test, the textile is moved across a surface coated with water droplets and the time taken for the water to roll off is measured.

In addition to these standardized tests, there are also industry-specific protocols that manufacturers may adopt. For instance, some companies may opt for accelerated aging tests to simulate the effects of prolonged exposure to moisture and temperature changes, which could affect the durability of their products. These tests can help identify any potential weaknesses in the material's hydrophobic properties early in the product development process.

One particularly interesting case study involves the use of hydrophobic nanoparticles in the production of waterproof clothing. Researchers at the University of California, Los Angeles (UCLA) have developed a textile with a hydrophobic layer that is resistant to water droplets and even small puddles. The layer is made from a combination of polyurethane and titanium dioxide nanoparticles, which provide excellent hydrophobicity and UV protection. The researchers tested this technology on a t-shirt and found that it significantly improved its water resistance compared to traditional cotton fabrics.

Another example comes from the automotive industry, where waterproofing is critical for maintaining the interior climate control system. Companies like Pirelli have developed specialized textiles for use in their tires that are designed to repel water and dirt. These materials are often coated with a special polymer that forms a barrier on the tire surface, effectively preventing water from entering the inner workings of the tire.

In conclusion, textile surface water repellency is a complex topic that involves both science and engineering principles. By understanding the underlying science behind these tests and exploring practical examples, we can gain a deeper appreciation for the importance of hydrophobicity in the design and application of textile materials. As technology continues to advance, we can expect to see even more innovative solutions that will enhance our ability to protect ourselves and our belongings from the elements.

纺织品表面拒水测试概述

随着现代生活水平的提高,人们对衣物舒适度和耐用性的要求也越来越高,纺织品表面拒水性能是衡量衣物质量的重要指标之一,本文将详细介绍纺织品表面拒水测试的方法和标准,并通过案例分析来说明其实际应用。

拒水测试方法与标准

测试方法

拒水测试主要采用模拟实际使用环境的方法,通过一系列实验来评估纺织品表面的防水性能,主要包括静态防水测试和动态防水测试两种方式,静态防水测试是在恒温恒湿环境下,模拟日常生活中的洗涤条件,观察纺织品表面的防水效果;动态防水测试则是在模拟不同水流速度和冲击力的条件下,测试纺织品面对水滴的吸附能力和抗滑性能。

测试标准

根据纺织品行业的相关标准和国际纺织行业协会的规定,拒水测试的标准主要包括以下几个方面:

(1)防水等级:根据纺织品表面的防水性能,将其分为不同的防水等级,如IP等级。

(2)测试方法:采用国际通用的防水性能测试方法,如接触角测试、吸水性测试等。

(3)实验条件:实验环境应保持恒温恒湿,模拟实际使用环境。

案例分析

某品牌纺织品表面拒水测试案例

某品牌近年来推出了一系列具有高防水性能的纺织品,以满足消费者对衣物耐久性和舒适性的需求,为了验证其产品的防水性能,该品牌进行了纺织品表面拒水测试。

在静态防水测试中,该品牌选择了不同的面料类型和颜色进行测试,通过使用专业的防水仪器和实验设备,对每一种面料进行静态防水性能的评估,结果显示,该品牌推出的纺织品在静态环境下表现出良好的防水性能,能够有效抵抗日常洗涤中的水分渗透。

在动态防水测试中,该品牌采用了模拟不同水流速度和冲击力的条件进行测试,通过观察纺织品面对水滴的吸附能力和抗滑性能,发现该品牌纺织品在面对水流冲击时表现出优秀的抗滑性能,能够有效防止衣物滑落。

纺织品拒水性能的国际标准对比

根据国际纺织行业协会的规定,纺织品拒水性能的标准主要包括以下几个方面:

(1)防水等级:根据纺织品表面的防水性能,将其分为不同的防水等级,如IP等级,不同国家和地区对于纺织品拒水性能的标准可能存在差异,要求纺织品具有良好的防水性能和耐用性。

(2)国际知名品牌纺织品拒水性能测试案例:通过对比国际知名品牌纺织品在拒水性能方面的表现,可以发现不同品牌之间的差距和差异,这些品牌在面料选择、生产工艺、实验设备等方面可能存在差异,但都致力于提高纺织品拒水性能和耐用性。

结论与建议

纺织品表面拒水性能是衡量衣物质量的重要指标之一,对于提高衣物耐久性和舒适度具有重要意义,通过拒水测试方法和标准的应用,可以评估纺织品表面的防水性能和耐用性,在实际应用中,可以根据不同国家和地区的标准要求,选择合适的面料类型和工艺流程,以提高纺织品拒水性能和耐用性,消费者在购买纺织品时也应该关注产品的防水性能和耐用性指标,选择符合自己需求的产品。

Articles related to the knowledge points of this article:

Where to Find Textile Four-Piece Wholesale Market

Exploring the Price Landscape of Shuzhi Ke Textiles:A Comprehensive Analysis

Exploring the Rich Tapestry of Nontong Xinmei Yang Textiles

Exploring the World of Textiles:A Journey Through Tide Happy Garment Trading