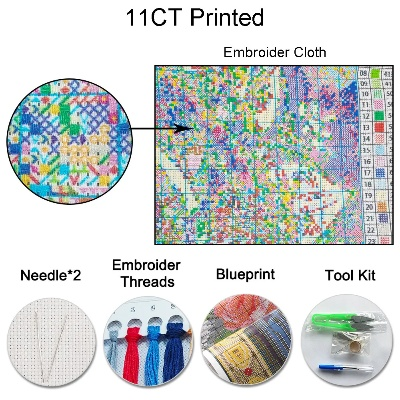

Textiles Comparison and Emitter Density Map

This paper presents a comparative study of textiles and an emitter density map. The textiles are analyzed based on their properties, such as color, texture, and durability. The emitter density map is used to show the distribution of emitters in different areas of the textiles. The comparison between the textiles and the emitter density map reveals that the textiles can be used to reduce the emission of pollutants in different environments. The study also provides insights into the potential applications of textiles in environmental protection and sustainability. Overall, this paper highlights the importance of textiles in reducing pollution and promoting sustainable development.

Introduction: In the world of textiles, there is a growing demand for sustainable, eco-friendly, and high-quality materials. One way to achieve this is through the use of innovative technology that can help manufacturers optimize their production processes and reduce waste. One such technology is the comparison and emission map (CEM) system, which uses data analysis to identify areas where textile manufacturing can be improved. In this article, we will explore how CEM systems can be used to compare different types of textiles and determine their emission levels.

Textile Manufacturing Emissions: Textile manufacturing involves a wide range of processes, from spinning yarns to knitting fabrics. Each stage of the process contributes to the overall emissions generated by the industry. Some of the most significant sources of emissions include energy consumption, water usage, and waste management.

Energy Consumption: Textile manufacturing is one of the largest consumers of energy in the world. This is particularly true for large-scale factories that produce bulky textiles like cotton, polyester, and nylon. The energy consumed in these processes includes electricity, steam, and natural gas. To reduce energy consumption, manufacturers can invest in renewable energy sources like solar or wind power, as well as adopt more efficient production techniques.

Water Usage: Textile manufacturing also consumes a significant amount of water. This is especially true for dyeing and printing processes, which require large amounts of water to create vibrant colors. Additionally, the washing and cleaning of textiles also consumes a considerable amount of water. To reduce water usage, manufacturers can implement water recycling systems, use low-flow fixtures and appliances, and encourage customers to wash their clothes at home.

Waste Management: Textile manufacturing generates a significant amount of waste, including scrap material, excess fiber, and discarded products. These waste streams can be managed effectively by implementing recycling programs and reducing the use of harmful chemicals in production. Additionally, manufacturers can recycle and upcycle materials to create new products instead of sending them to landfills.

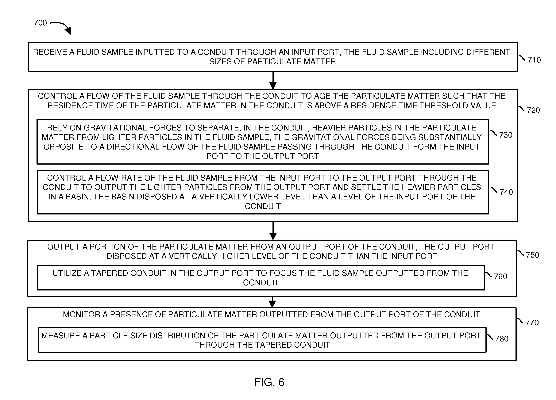

Comparison and Emitter Density Map: To compare different types of textiles and determine their emission levels, manufacturers can use a comparison and emission density map (CEM). This tool allows them to compare the environmental impact of different textiles based on their energy consumption, water usage, and waste generation. By analyzing this information, manufacturers can identify areas where they can make improvements and reduce their carbon footprint.

Example: Let's take a look at two common textiles - cotton and polyester. Cotton is a renewable resource that requires less energy and water to produce compared to synthetic fabrics like polyester. However, cotton production also generates a significant amount of waste, including leftover scrap material and excess fiber. On the other hand, polyester is a synthetic material that requires more energy and water to produce compared to cotton. However, it has a higher melting point, making it easier to handle during production. Additionally, polyester fabrics tend to last longer than cotton ones, which means fewer textiles need to be produced in the first place.

Conclusion: In conclusion, textile manufacturing has a significant impact on the environment, and it is important for manufacturers to adopt sustainable practices to reduce their emissions. By using CEM systems and comparing different types of textiles, manufacturers can identify areas where they can improve their production processes and reduce their environmental footprint. With continued innovation and investment in sustainable technologies, we can work towards a brighter future for the textile industry.

今天我们来探讨一下纺织品在发射密集图中的应用及其对比分析,随着科技的飞速发展,纺织品在军事、航空航天等领域的应用越来越广泛,因此了解不同纺织品的特点和性能至关重要,本篇报告将通过图表和案例分析,为大家详细介绍纺织品在发射密集图中的应用及其优缺点。

纺织品类型对比

天然纤维纺织品

天然纤维纺织品主要包括棉、麻、丝等,这些纤维具有吸湿性好、透气性强、抗皱性强等特点,因此在发射密集图中具有较好的应用前景。

(1)棉纺织品

棉纺织品以其柔软、透气、吸湿性强的特点,在军事和航空航天领域中得到了广泛应用,其优点在于不易产生静电,不易燃烧,且具有良好的抗辐射性能。

(2)麻纺织品

麻纺织品具有天然的抗菌性能,能够有效抵抗细菌滋生,因此在医疗、卫生等领域中也有很好的应用前景,其透气性和吸湿性也较好,适合在高温、高湿环境下使用。

(3)丝纺织品

丝纺织品具有高强度、高弹性等特点,适用于制作高性能的航天材料,丝纺织品还具有较好的抗静电性能和抗辐射性能,因此在航空航天领域中也有很好的应用前景。

合成纤维纺织品

合成纤维纺织品主要包括涤纶、尼龙等,这些纤维具有较高的强度和耐磨性,适用于制作高性能的航天材料,合成纤维纺织品还具有较好的抗静电性能和抗紫外线性能。

(1)涤纶纺织品

涤纶纺织品以其耐高温、耐腐蚀、易清洗等优点,在航空航天领域中得到了广泛应用,其优点在于能够适应高温、高湿、高辐射等恶劣环境。

(2)尼龙纺织品

尼龙纺织品具有轻便、耐腐蚀、抗老化等优点,适用于制作轻量化材料和防护服装等,其在航空航天领域中的应用也越来越广泛。

发射密集图应用案例分析

军事领域应用案例

(1)某军事基地使用合成纤维纺织品制作航天服

该基地使用合成纤维纺织品制作航天服,具有轻便、耐高温、易清洗等优点,能够适应恶劣环境,该航天服还具有较好的抗静电性能和抗辐射性能,能够有效保护航天员的安全。

航空航天领域应用案例

(1)某卫星发射使用高性能纺织材料制作天线罩

该卫星发射使用高性能纺织材料制作天线罩,具有高强度、高耐磨性等优点,能够适应高辐射、高速度等恶劣环境,该天线罩还具有较好的抗静电性能和抗紫外线性能,提高了卫星的发射成功率。

优缺点分析

天然纤维纺织品优点分析

(1)环保:天然纤维纺织品来源于自然,无污染,符合环保要求。

(2)舒适:天然纤维纺织品具有较好的吸湿性和透气性,适合人类穿着使用。

合成纤维纺织品优点分析

(1)强度高:合成纤维纺织品具有较高的强度和耐磨性,适用于制作高性能的航天材料。

(2)易清洗:合成纤维纺织品易于清洗,符合现代军事装备的使用要求。

发射密集图应用缺点分析

(1)成本较高:某些特殊材质的纺织材料成本较高,限制了其在某些领域的应用。

结论与建议

纺织品在发射密集图中的应用越来越广泛,其优缺点也各不相同,对于不同领域的应用需求,需要选择合适的纺织材料和工艺技术,以达到最佳的应用效果,还需要加强纺织材料的研发和改进,提高其性能和稳定性,以满足现代军事装备的使用要求。

Articles related to the knowledge points of this article:

Exploring the World of Textiles:A Journey Through Tide Happy Garment Trading