Breaking Down Textiles into Powder:A Comprehensive Guide

This comprehensive guide demystifies the process of breaking down textiles into powder, a crucial step in various industrial processes. It provides an in-depth understanding of the various techniques and equipment used for this task, highlighting the importance of maintaining high standards of cleanliness and safety during the process. The guide covers topics such as the selection of appropriate machinery, the cleaning and drying of textiles, the preparation of the pulp, and the final steps of sieving and packaging. By following these steps, textile manufacturers can ensure that their products meet stringent quality standards and are ready to be used in various applications.

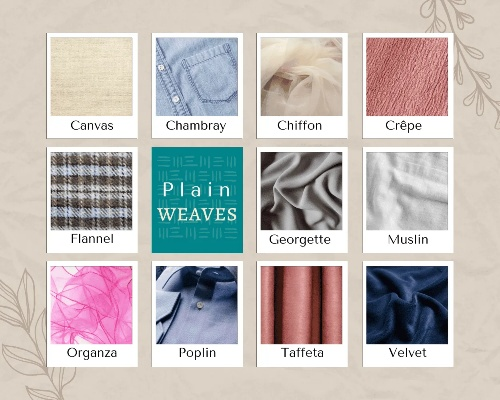

Textiles, the fabrics that make up our clothing and furnishings, are made from a variety of materials including cotton, wool, silk, polyester, and more. However, when it comes to their end-of-life disposal, one common method is to convert them into powder, which can then be used in various industries such as construction or even as a fertilizer. In this guide, we'll explore how textiles can be broken down into powder and provide an overview of the process using a table to illustrate key steps.

Table: Textile Breakdown Process

| Stage | Method | Description |

|---|---|---|

| 1 | Collection | Gathering textile scraps from waste streams or recycling facilities. |

| 2 | Pretreatment | Cleaning and separating the textile scraps to remove impurities and debris. |

| 3 | Chemical Treatment | Applying chemicals to break down the fibers into smaller pieces. |

| 4 | Fiber Disintegration | Using mechanical means like grinders or crushers to further reduce the size of the fibers. |

| 5 | Drying | Draining out the water content from the fibers to create a dry powder. |

| 6 | Packaging | Securing the powder for transport or storage. |

Case Study: Recycling Cotton Scraps into Powder

Let's take the example of cotton, a widely used textile material due to its softness and breathability. Here's how cotton scraps could be turned into powder through a typical textile recycling process:

-

Collection: Cotton scraps are collected from old clothes, textiles, and other sources. These scraps are often found in textile waste streams.

-

Pretreatment: The cotton scraps undergo cleaning and separation to remove any remaining dirt or contaminants. This step ensures that the subsequent chemical treatment can proceed effectively.

-

Chemical Treatment: To break down the cotton fibers, a solution of sodium hypochlorite (bleach) is applied to the cotton scraps. Hypochlorite acts as a strong oxidizing agent that breaks down the cellulose structure of the cotton fibers.

-

Fiber Disintegration: Once the cotton fibers have been dissolved by the bleach, they are ground using a high-speed grinder to further reduce their size. This process results in a fine powder that is easier to handle and transport.

-

Drying: The resulting cotton powder is then dried using a dryer to remove any moisture. This step is crucial for preventing the growth of mold and ensuring the powder's stability.

-

Packaging: Finally, the cotton powder is packaged in airtight containers for easy transportation and storage.

Conclusion

By breaking down textiles into powder, we not only conserve resources but also contribute to environmental sustainability. The process described here is just one example of how textile recycling can be achieved. As demand for textile products continues to grow, investing in efficient textile recycling methods will become increasingly important for both economic and ecological reasons.

大家好,今天我们来探讨一下纺织品如何破碎成粉末,在日常生活和工业生产中,这种处理方式非常常见,尤其在纺织材料的深加工领域,下面我们将通过图表和案例详细说明。

破碎纺织品的方法

机械破碎:这是最常见的破碎方式,通过使用各种破碎机,如破碎锤、破碎筛等,将纺织品破碎成粉末。

(表格1)

热处理破碎:在某些情况下,纺织品可以通过高温热处理的方式破碎成粉末,某些纤维经过高温处理后,其内部结构发生变化,从而更容易被破碎成粉末。

某纺织厂使用热处理破碎技术处理废旧纺织品

某纺织厂处理大量废旧纺织品时,采用了热处理破碎技术,他们利用高温设备将废旧纺织品进行热处理,使其内部结构发生变化,然后通过破碎机将其破碎成粉末,这种处理方式不仅减少了废旧纺织品的污染,还提高了其回收利用率。

粉末特性与用途

破碎成粉末的纺织品具有许多优点,例如便于运输、储存和加工,这些粉末还可以用于各种领域,如涂料、粘合剂、填料等,它们在涂料、粘合剂等领域有着广泛的应用前景。

(表格2)

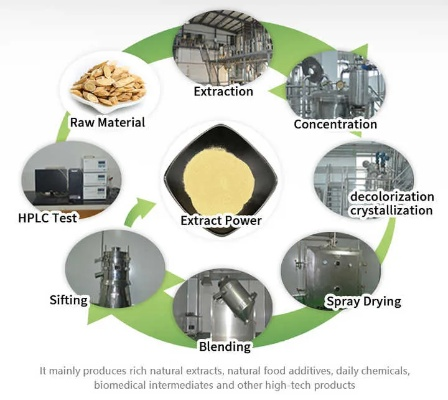

破碎工艺与设备介绍

-

破碎工艺:在纺织品的破碎过程中,需要经过多个工序,包括原料准备、破碎、筛分等,这些工序的合理安排和设备选择对于提高破碎效率和质量至关重要。

-

设备介绍:常见的纺织品破碎设备包括破碎机、筛网等,不同类型的设备适用于不同的破碎工艺和需求,大型破碎机适用于大型废旧纺织品的破碎;筛网则用于筛分和分离不同粒度的粉末。

案例分析

以某纺织公司为例,他们成功将废旧纺织品破碎成粉末,并应用于涂料和粘合剂领域,该公司采用了先进的热处理破碎技术,将废旧纺织品进行高温处理后破碎成粉末,这种处理方法不仅提高了废旧纺织品的回收利用率,还提高了产品的附加值,这些粉末在涂料和粘合剂领域有着广泛的应用前景,可以用于制造高质量的涂料和粘合剂产品。

纺织品破碎成粉末是一种常见的处理方法,它具有许多优点和应用前景,通过合理的工艺和设备选择,可以有效地提高破碎效率和质量,这种处理方法也符合可持续发展的理念,有利于环境保护和资源利用,在实际应用中,我们还需要注意设备的维护和保养,以确保其长期稳定运行。

Articles related to the knowledge points of this article:

The Story of Lanzhou Haitao Textile Company