纺织厂Quality Control in Action:A Comprehensive Guide

: Quality Control in Action: A Comprehensive Guide for Textile Factories,Abstract:,Quality control is a critical component of textile production, ensuring that products meet industry standards and consumer expectations. This comprehensive guide provides essential strategies and best practices for implementing effective quality control measures within textile factories. It covers topics such as inspection procedures, testing methods, supplier management, and employee training, offering practical advice to optimize the quality control process. By following these guidelines, textile manufacturers can improve product reliability, enhance customer satisfaction, and maintain competitive advantage in the market.

Introduction: Quality control (QC) is the cornerstone of any manufacturing process, especially in the textile industry, where precision and consistency are paramount. In this article, we will delve into the various aspects of QC in a textile plant, including its importance, methods, challenges, and practical examples to illustrate how it works in real-world scenarios.

Importance of Quality Control in Textile Plants: Quality control in textile plants is crucial for ensuring product consistency, meeting customer expectations, and maintaining brand reputation. It helps to identify and correct defects in raw materials, fabrics, and finished products, thereby preventing costly rework and customer complaints. Additionally, QC ensures that the environmental impact of the manufacturing process is minimized by using sustainable materials and processes.

Methods of Quality Control:

-

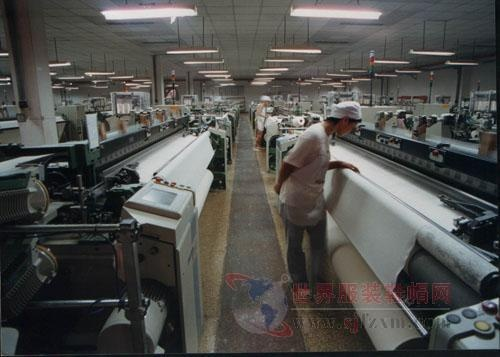

Inspection: This involves visually checking the quality of raw materials, fabrics, and finished products. The inspection process can be done manually or through automated equipment such as optical scanners or machine vision systems.

-

Testing: Various tests are conducted on raw materials and fabrics to ensure they meet specific standards. These tests include strength testing, colorfastness testing, and tear resistance testing.

-

Process Control: Monitoring the manufacturing process helps to identify potential problems early on and take corrective action before the product leaves the factory. This includes monitoring temperature, humidity, and other process parameters.

-

Quality Audits: Regular audits are conducted to evaluate the effectiveness of QC measures and identify areas for improvement. These audits may involve reviewing records, conducting interviews with employees, and inspecting finished products.

Challenges in Quality Control: One of the biggest challenges in QC is ensuring consistency across different production runs. Variations in raw material quality, machine settings, and human error can all contribute to variations in product quality. Additionally, new technologies and materials can introduce new challenges for QC professionals.

Practical Examples: Let's consider a case study from a leading textile company in Europe. The company had a significant problem with defective socks due to poor quality control during the knitting process. To address this issue, the company implemented a comprehensive QC plan that included regular training for employees, improved automation in the knitting process, and more stringent inspection criteria. Over a period of six months, the company saw a significant reduction in defective socks, demonstrating the effectiveness of their QC efforts.

Conclusion: In conclusion, quality control plays a critical role in the success of a textile plant. By implementing effective QC measures, companies can ensure consistent product quality, meet customer expectations, and maintain their competitive edge in the market. As demonstrated in the case study, investing in QC can lead to significant improvements in product quality and profitability.

大家好,今天我们将探讨纺织厂中的QC(质量控制)实践及其案例,QC在纺织行业中扮演着至关重要的角色,它不仅提高了产品质量,还为企业带来了更高的竞争力,下面我们将通过图表和案例详细说明。

纺织厂QC概述

QC在纺织厂中主要涉及产品质量检测、控制以及改进等方面的工作,它通过一系列的科学方法和工具,确保生产出的产品符合相关标准和客户要求,QC团队负责制定质量标准、执行检验流程、处理质量问题等。

纺织厂QC实践案例

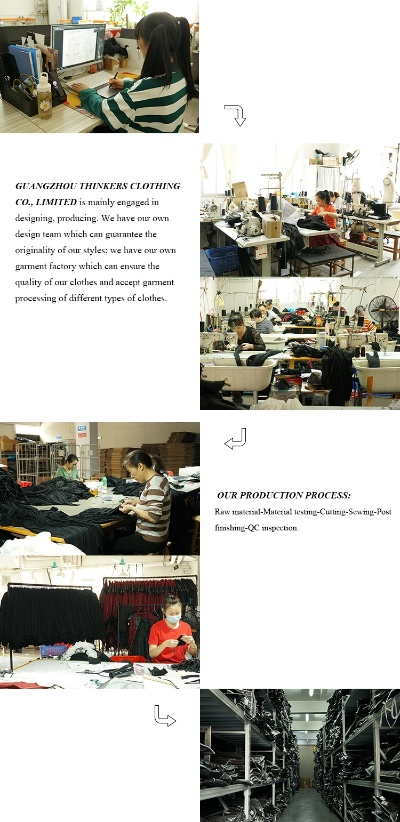

高效的质量检测流程

某纺织厂采用了先进的QC实践,成功提高了产品质量,该厂采用了自动化检测设备,大大提高了检测效率和质量,QC团队制定了详细的检验流程,确保每个环节都符合标准,在实际操作中,QC团队定期对设备进行维护和校准,确保其准确性和可靠性,通过这一流程,该厂的产品质量得到了显著提升,客户满意度也得到了提高。

预防性质量控制措施

某纺织厂实施了预防性质量控制措施,有效避免了质量问题,该厂在生产过程中实施了严格的原材料控制、过程控制和最终检验流程,QC团队定期进行质量分析,找出潜在的问题和风险点,并制定相应的改进措施,该厂还建立了质量反馈机制,及时收集和处理客户反馈,不断优化产品质量和生产流程,通过这些措施,该厂的产品质量得到了持续的保障。

图表补充说明

以下是用图表补充说明的纺织厂QC实践的相关内容:

(请在此处插入图表)

英文案例说明

英文案例一:纺织厂质量检测流程优化

The textile factory has optimized its quality testing process to improve product quality. The factory has implemented automated testing equipment that significantly increases testing efficiency and quality. Additionally, the QC team has developed detailed testing procedures to ensure that each step meets the standards. In practice, the QC team regularly maintains and calibrates the equipment to ensure its accuracy and reliability. As a result, the quality of the products produced by the factory has been significantly improved, and customer satisfaction has also increased.

英文案例二:预防性质量控制策略实施

A textile factory implemented preventive quality control strategies to avoid quality issues. The factory implemented strict controls on raw materials, processes, and final inspection procedures throughout the production process. Additionally, the QC team conducted regular quality analyses to identify potential issues and risks, and developed corresponding improvement measures. Furthermore, the factory established a quality feedback mechanism to collect and handle customer feedback in a timely manner, continuously optimizing product quality and production processes. As a result, the quality of the products produced by the factory remains guaranteed.

Articles related to the knowledge points of this article:

The Story of the Four Diversified Textiles Factory