The Importance of Textile Inspection in Quality Control

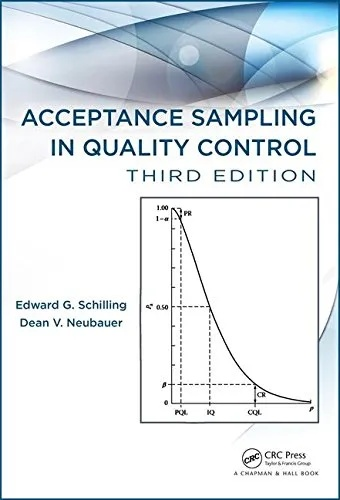

In the realm of quality control, textile inspection stands as a critical component that ensures the end product meets industry standards and consumer expectations. This process involves a thorough examination of fabrics to identify any defects or flaws that could compromise their performance or safety. The importance of textile inspection cannot be overstated, as it serves as a safeguard against costly rework and customer dissatisfaction. By employing advanced techniques and equipment, inspectors can accurately detect even the most subtle imperfections, thereby ensuring that each piece of textile is of the highest quality. In addition, the use of automated inspection systems has revolutionized the industry, allowing for faster and more efficient inspections, resulting in improved efficiency and cost savings. As such, the importance of textile inspection cannot be underestimated, and its implementation must be prioritized in order to maintain the integrity of our products and meet the demands of our customers.

Introduction: In the ever-evolving global market, quality control is paramount for any industry. Among these industries, the textile sector stands out as a critical one, where the fabric and materials used to make clothing, home furnishings, and other textile products are vital for consumer satisfaction and brand reputation. One aspect that contributes significantly to the overall quality of textile products is the thorough inspection process. This essay will delve into the significance of textile inspection, highlighting its importance in ensuring product reliability and customer satisfaction.

Textile Inspection Process: Before we dive into the importance of textile inspection, it's essential to understand what it entails. The inspection process involves several stages, including but not limited to:

- Pre-inspection: This stage includes sorting the raw materials and checking their physical properties such as color, texture, and density.

- In-process inspection: During the manufacturing process, various parameters like thread count, yarn quality, and dyeing consistency are monitored.

- Post-inspection: Finally, the finished product undergoes a comprehensive check for any defects or irregularities.

Importance of Textile Inspection: Textile inspection plays a crucial role in maintaining product quality, preventing defects from reaching the consumer, and reducing costs associated with defective products. Here are some key points on why textile inspection is so important:

-

Ensuring Product Reliability:

- Quality Control: Regular inspection ensures that every piece of fabric meets the standards set by the manufacturer or the industry standards.

- Product Lifespan: By identifying potential issues early on, defects can be corrected before they affect the lifespan of the product.

- Consumer Safety: Products free from defects pose less risk to consumers, minimizing the possibility of harm or injury.

-

Reducing Costs:

- Preventing Defects: Early detection and correction of defects saves time and resources spent on fixing them later.

- Quality Assurance: Completing inspections ensures that only high-quality products reach the market, reducing the need for rework or scrapping.

- Cost Efficiency: By investing in effective inspection processes, businesses can optimize their production and reduce waste.

-

Improving Brand Image:

- Customer Trust: A reliable inspection process builds trust with customers, making them more likely to buy from the brand again.

- Brand Reputation: A consistent high standard of quality helps maintain a reputable brand image, which can lead to increased loyalty and repeat business.

-

Advancing Market Competitiveness:

- Compliance with Regulations: Companies that invest in robust inspection processes often comply with stringent regulations, which can give them an edge over competitors who don't.

- Global Standards: Many international markets require textile products to meet specific standards. Compliance with these standards enhances a company's ability to enter new markets.

-

Providing Customer Service:

- Resolution of Concerns: Regular inspections allow companies to address any concerns raised by customers about the quality of their products.

- Enhanced Customer Experience: When customers receive products that meet their expectations, they are more likely to have a positive experience, leading to increased customer satisfaction and loyalty.

Case Study: Consider the case of a well-known clothing brand, which faced a significant challenge when a major defect was discovered in a batch of shirts during a routine inspection. The defect led to a recall of the entire lot, resulting in substantial losses for the company. However, after implementing a more rigorous inspection protocol and investing in advanced technology for real-time monitoring, the company was able to prevent similar incidents in future batches. This change in approach not only improved the quality of the products but also boosted customer confidence and loyalty, ultimately leading to a recovery in sales and a rise in profits.

Conclusion: In conclusion, textile inspection is an integral part of maintaining the quality of textile products. It not only ensures that each piece meets the standards set for excellence but also contributes to cost savings, improved brand image, and enhanced customer service. By investing in robust inspection procedures, businesses can safeguard their reputation and ensure long-term success in today's competitive market. Therefore, it's crucial for all stakeholders involved in the textile industry to prioritize quality control through proper inspection processes.

纺织品作为日常生活中不可或缺的物品,其质量直接关系到人们的穿着舒适度和产品的安全性,纺织品检测在纺织品生产和销售过程中具有至关重要的地位,本文将重点探讨纺织品检测的重要性及其在具体案例中的应用。

纺织品检测的重要性

保障产品质量

纺织品检测是确保产品质量的重要手段,通过检测,可以确保纺织品符合国家或行业标准,保证产品的安全性和可靠性,纺织品检测还可以帮助企业及时发现并解决生产过程中的问题,提高生产效率和质量。

维护消费者权益

纺织品作为人们日常穿着的重要物品,其质量直接关系到消费者的穿着体验和身体健康,纺织品检测对于维护消费者权益具有重要意义,通过检测,可以确保纺织品符合相关标准和法规,保障消费者的合法权益。

推动行业健康发展

纺织品检测是推动行业健康发展的重要手段,随着人们对纺织品质量要求的不断提高,纺织品检测行业也在不断发展壮大,通过加强纺织品检测,可以提高整个行业的生产水平和技术水平,推动行业健康发展。

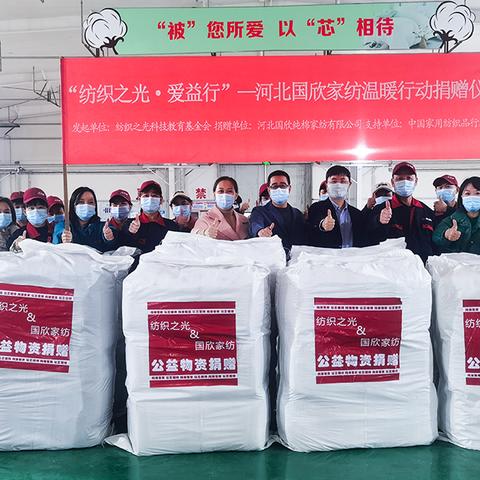

纺织品检测的具体案例

国内某知名品牌纺织品检测过程

某国内知名品牌在生产过程中,对每一批次的纺织品都进行了严格的检测,该品牌注重产品质量和消费者权益,因此在生产过程中严格遵守国家相关标准和法规,通过严格的检测,确保了每一批次的纺织品都符合国家标准和质量要求,该品牌还积极推广纺织品检测的重要性,提高消费者的认知度和信任度。

国外知名品牌纺织品检测案例分析

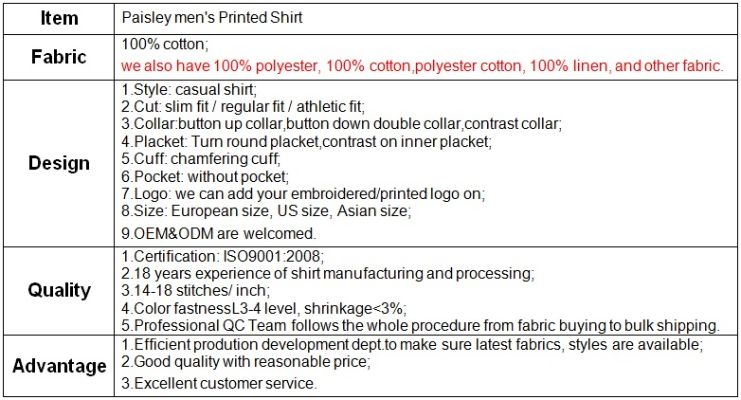

在国外市场上,一些知名品牌的纺织品也经过了严格的检测,这些品牌注重产品质量和安全性能,因此在生产过程中采用了先进的检测技术和设备,通过先进的检测技术和设备的应用,这些品牌可以快速准确地检测出纺织品中的各种问题,并及时采取措施解决,这些品牌的纺织品也得到了广大消费者的认可和好评。

纺织品检测的表格说明

以下是关于纺织品检测的表格说明:

| 项目 | 描述 | 示例数据 |

|---|---|---|

| 重要性 | 保障产品质量、维护消费者权益、推动行业健康发展 | 通过严格检测确保产品质量符合国家标准和质量要求 |

| 具体案例 | 国内知名品牌纺织品的生产过程 | 该品牌注重产品质量和消费者权益,严格遵守国家相关标准和法规 |

| 国外知名品牌纺织品的生产过程 | 采用先进的检测技术和设备,快速准确地检测出纺织品中的各种问题 | 这些品牌的产品得到了广大消费者的认可和好评 |

纺织品检测对于保障产品质量、维护消费者权益、推动行业健康发展具有重要意义,通过加强纺织品检测,可以提高整个行业的生产水平和技术水平,促进纺织品的健康发展,纺织品检测也是保障消费者权益的重要手段之一,我们应该重视纺织品检测的重要性,加强纺织品的检测工作,提高纺织品的品质和安全性能。

Articles related to the knowledge points of this article:

The Dynamics of Jinwang Textiles:A Global Fabrication and Market Leader

Cost of Customized Fabrics in Jilin:A Comprehensive Guide

纺织品CCS:A Comprehensive Guide to Global Carbon Capture Standards for Textiles

Breaking Barriers and Unleashing Potential at the Frankfurt Textile Expo