Understanding the Science Behind Textile Emulsions:A Comprehensive Guide

"Understanding the Science Behind Textile Emulsions: A Comprehensive Guide" is a comprehensive guide to understanding the science behind textile emulsions. This guide provides readers with an in-depth understanding of the science behind textile emulsions, including the different types of textile emulsions, their applications, and their properties.,The guide begins by introducing the basic concepts of textile emulsions, including their definition, classification, and applications. It then goes on to discuss the different types of textile emulsions, such as waterborne, solvent-based, and oil-based textile emulsions. The guide also covers the factors that affect the performance of textile emulsions, such as temperature, pH, and shear rate.,In addition to the science behind textile emulsions, the guide also provides practical tips for using textile emulsions in various industries, such as printing, coating, and finishing. It includes case studies and examples to illustrate how textile emulsions can be used effectively in these industries.,Overall, "Understanding the Science Behind Textile Emulsions: A Comprehensive Guide" is an essential resource for anyone interested in textile emulsion technology. With its comprehensive coverage of the science behind textile emulsions, it provides readers with a solid foundation for understanding and applying this technology in their own work.

Introduction: Textile emulsions are a crucial component in the production of textile materials, including fabrics, carpets, and upholstery. These emulsions are made by combining oil-based substances with water to create a homogeneous mixture that can be used as a binder or coating for textile fibers. In this guide, we will explore the principles behind the preparation of textile emulsions and provide insights into their applications and benefits.

Emulsion Preparation Principles: To understand the science behind textile emulsions, it is essential to first understand the basic principles of emulsion formation. An emulsion is a heterogeneous system where oil droplets are suspended in a continuous phase of water. The formation of an emulsion involves three main steps:

-

Oil-Water Interaction: The primary driving force behind emulsion formation is the interfacial tension between the oil and water phases. When two immiscible liquids come into contact, they form a meniscus at the interface. The interfacial tension is influenced by various factors, such as the polarity of the molecules, temperature, and the presence of surfactants.

-

Surfactant Role: Surfactants are chemicals that reduce the interfacial tension between oil and water. They adsorb onto the oil-water interface and form micelles, which are small aggregates of surfactant molecules surrounding the oil droplets. This reduces the surface energy of the oil-water interface, making it easier for the oil droplets to coalesce and form an emulsion.

-

Coalescence and Osmosis: As the emulsion is stirred or subjected to external forces, the oil droplets may coalesce (merge together) due to their similar densities or osmosis (flow of solvent from a region of lower concentration to a region of higher concentration). This process results in the formation of a stable emulsion.

Applications and Benefits: Textile emulsions have numerous applications in the textile industry, including:

-

Binders: Emulsions serve as binders for textile fibers, enhancing their strength and durability. For example, polyurethane emulsions are commonly used as adhesives in carpet manufacturing, while silicone emulsions are used in upholstery to provide flexibility and moisture resistance.

-

Coatings: Emulsions can also be applied as coatings on textile fibers, providing antistatic properties, flame resistance, and other functional properties. For instance, polyvinyl alcohol (PVA) emulsions are widely used as coatings for cotton fabrics to improve their moisture absorption and breathability.

-

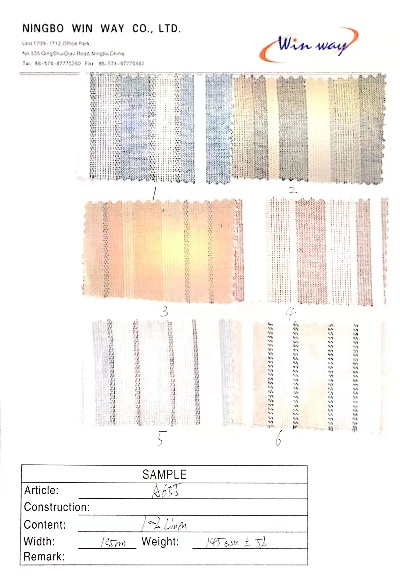

Decorative Applications: Emulsions can also be used in decorative applications, such as creating patterns on fabrics or adding color to upholstery. For example, latex emulsions can be used to apply patterns on carpets, while dyed emulsions can be incorporated into upholstery fabrics to achieve vibrant colors.

Case Study: One example of the application of textile emulsions is the use of silicone emulsions in upholstery. Silicone emulsions provide excellent moisture resistance, flexibility, and durability to upholstered furniture, making them ideal for high-traffic areas like living rooms and bedrooms. The use of silicone emulsions has led to increased customer satisfaction and reduced maintenance costs for upholstered furniture manufacturers.

Conclusion: In conclusion, textile emulsions play a crucial role in the production of textile materials, offering a range of benefits and applications. By understanding the principles behind their preparation and exploring their diverse uses, we can further enhance our understanding of this important technology in the textile industry.

纺织品乳液是一种新型功能性材料,具有优异的分散性、稳定性及功能性,其制备原理主要涉及乳化剂的选择、乳化剂与纤维的相互作用以及乳液的形成过程,本文将详细阐述纺织品乳液的制备原理,并结合实际案例进行说明。

纺织品乳液制备原理

乳化剂的选择

乳液制备的关键在于选择合适的乳化剂,乳化剂的作用是使分散相与连续相之间形成稳定的界面,从而实现分散、稳定和均匀混合,常见的乳化剂包括表面活性剂、高分子聚合物等。

表面活性剂是乳液制备中常用的乳化剂之一,其分子结构中包含亲水基团和亲油基团,能够降低界面张力,增加分散相与连续相之间的亲和力,表面活性剂还能提高乳液的稳定性,防止在加工过程中出现分层现象。

乳化过程

乳化过程是纺织品乳液制备的核心步骤之一,在乳化过程中,首先将纤维与乳化剂混合,形成纤维悬浊液,通过适当的搅拌、剪切等作用力,使纤维悬浊液中的分散相与连续相充分混合,形成稳定的乳液,在这个过程中,还需要控制乳液的稳定性,避免在后续加工过程中出现分层现象。

乳液形成过程

乳液的形成过程涉及多个物理化学变化,纤维与乳化剂发生相互作用,形成稳定的纤维悬浊液,通过剪切作用力,使分散相与连续相之间形成稳定的界面,界面上的界面张力逐渐降低,形成稳定的乳液,通过适当的加工工艺,如喷雾干燥、流延等,将乳液加工成所需的纺织品。

实际案例说明

纺织品乳液制备案例一:某公司生产功能性印花布的工艺流程

某公司采用特定的乳化剂和纤维原料制备纺织品乳液,将纤维原料与特定的乳化剂混合,形成纤维悬浊液,通过适当的搅拌和剪切作用力,使纤维悬浊液中的分散相均匀分布,经过喷雾干燥等工艺处理,最终得到具有特定功能的印花布,该案例表明,合理的乳液制备工艺可以大大提高纺织品的性能和品质。

纺织品乳液制备案例二:某品牌化妆品的配方优化

某品牌化妆品采用纺织品乳液作为其主要成分之一,在配方优化过程中,通过实验确定合适的乳化剂种类和用量,以及纤维原料的选择和配比,经过优化后的配方能够更好地满足消费者的需求和期望,提高产品的质量和性能,纺织品乳液的制备过程也符合环保、可持续性的要求。

纺织品乳液的制备原理涉及多个物理化学过程,包括纤维与乳化剂的相互作用、界面张力的调节、剪切作用力的应用等,在实际应用中,合理的乳液制备工艺可以提高纺织品的性能和品质,同时符合环保、可持续性的要求,实际案例也表明了纺织品乳液在化妆品、功能性材料等领域的应用前景广阔。

在未来的研究中,可以进一步探索纺织品乳液的优化制备方法,提高其稳定性和功能性,以满足更多领域的需求,也需要关注纺织品乳液的环保性、可持续性等方面的研究与应用。

Articles related to the knowledge points of this article:

The Fabric of Culture:An Exploration into the World of Mian Tong Textiles