Textile Antistatic Standards and Their Impact on Quality Control

Antistatic properties are essential for textile products to maintain their quality and prevent electrostatic discharges that can cause damage. Standards set by international organizations like the International Organization for Standardization (ISO) and ASTM have been instrumental in ensuring that textiles meet these requirements. These standards not only define the minimum levels of antistatic properties but also provide guidelines on how to measure and evaluate them. The impact of these standards is felt across all stages of the manufacturing process, from raw material sourcing to final product inspection. By adhering to these standards, manufacturers can ensure that their products meet consumer expectations and avoid potential quality issues. Overall, the implementation of textile antistatic standards has had a significant impact on the quality control of textile products, promoting safety, reliability, and long-term performance.

Introduction: Textiles are an integral part of our lives, from everyday wear to high-end fashion. However, they can be prone to static electricity, which can cause discomfort and even damage sensitive electronic devices. In this article, we will discuss the various antistatic standards that govern textile products and how these standards affect quality control in the industry.

Antistatic Standards: There are several international standards for textiles, including EN ISO 13485, ASTM D3276, and ANSI/ESD S20. These standards provide guidelines for the production and testing of textile products to ensure that they meet specific requirements for antistatic properties.

EN ISO 13485: This standard is a global standard for the electrostatic discharge (EDS) of textiles. It covers the design, manufacture, and testing of textiles for EDS resistance. The standard requires that textiles have a minimum EDS resistance of 100 V/m when tested at a frequency of 1 kHz.

ASTM D3276: This standard provides guidance on the measurement of antistatic properties using a conductive probe method. It covers the selection of appropriate test parameters and the interpretation of results.

ANSI/ESD S20: This standard is designed for the protection of sensitive electronic equipment against electrostatic discharge. It specifies the minimum levels of antistatic protection required for different types of electronic components.

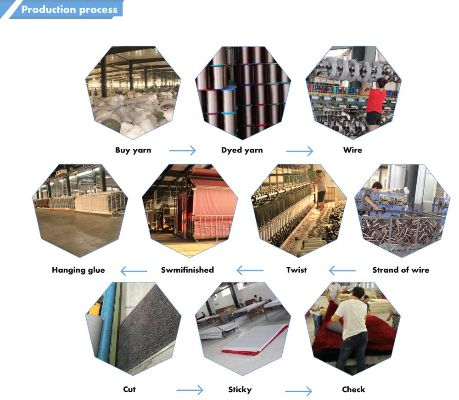

Quality Control: Quality control is crucial in ensuring that textile products meet the specified antistatic standards. Here are some steps that manufacturers can take to achieve this:

Designing: The first step in designing textile products is to consider their intended use and the potential sources of static electricity. For example, if the product is intended for use in a manufacturing environment, it may need to be designed with antistatic coatings or materials.

Material selection: The choice of materials is also important in achieving the desired antistatic properties. Some materials, such as polyester and nylon, naturally have low EDS resistance, while others, such as polyurethane and acetate, can be treated with antistatic agents to improve their performance.

Processing: Once the materials are selected, they need to be processed to achieve the desired antistatic properties. This may involve applying antistatic agents or coatings to the fabric, or using special machinery to reduce friction and create static electricity.

Testing: Finally, the textile products need to be tested to ensure that they meet the specified antistatic standards. This testing should be done both during the design process and after the product has been manufactured.

Case Study: One example of a textile product that meets the EN ISO 13485 standard is a car seat cover. This product is designed to protect children's skin from static electricity and other environmental hazards. To achieve the required EDS resistance, the manufacturer uses a combination of antistatic agents and coatings that are applied to the fabric before it is woven into the final product. After manufacturing, the car seat cover is tested using the ASTM D3276 method to ensure that it meets the specified level of antistatic protection.

Conclusion: Textile products that meet the specified antistatic standards not only provide better comfort and protection for users but also help to prevent damage to sensitive electronic devices. By following the guidelines outlined in international standards such as EN ISO 13485, ASTM D3276, and ANSI/ESD S20, textile manufacturers can ensure that their products meet the highest quality standards and provide customers with peace of mind.

纺织品的抗静电概述

随着现代工业的快速发展,纺织品的抗静电性能越来越受到重视,纺织品的抗静电性能不仅关系到产品的使用舒适度,还关系到人们的生产生活环境,为了确保纺织品在使用过程中不产生静电,我们制定了相应的抗静电标准。

抗静电纺织品的标准要求

抗静电性能测试方法

为了确保纺织品的抗静电性能符合国家标准,我们制定了严格的抗静电性能测试方法,这些测试方法包括但不限于接触电压测试、摩擦系数测试等,通过这些测试,可以全面评估纺织品的抗静电性能,确保其符合相关标准。

抗静电标准参数

根据国家标准,纺织品的抗静电性能应满足以下参数要求:

(1)接触电压:纺织品在接触不同金属导体时产生的电压应小于或等于特定数值。 (2)摩擦系数:纺织品在正常摩擦条件下应具有良好的摩擦性能,不易产生静电。 (3)安全标准:纺织品应符合相关安全标准,确保使用过程中不会对人体造成伤害。

抗静电纺织品的具体标准案例

某品牌纯棉衬衫

该品牌纯棉衬衫采用了特定的纺织工艺和材料,经过严格的质量控制,其抗静电性能符合国家标准,该衬衫在穿着过程中不易产生静电,提高了穿着的舒适度,该衬衫还具有优良的透气性和吸湿性,适合各种环境使用。

某公司导电纤维面料

某公司生产的导电纤维面料采用了特殊的导电纤维材料,具有出色的抗静电性能,该面料在生产过程中严格控制了纤维的排列和结构,确保了其良好的导电性能和抗静电性能,该面料广泛应用于电子、电器等领域,具有广泛的应用前景。

抗静电纺织品的标准补充说明

测试方法补充说明

除了上述的测试方法外,我们还需要对测试过程中的细节进行补充说明,在接触电压测试中,需要严格控制金属导体的种类和数量,以确保测试结果的准确性,在摩擦系数测试中,需要使用专业的摩擦仪进行测试,以确保测试结果的客观性。

安全标准补充说明

在抗静电纺织品的安全标准方面,我们需要考虑到纺织品可能对人体产生的潜在影响,我们需要在产品说明书中明确标注纺织品的安全标准,并提醒消费者在使用过程中注意安全,我们还需要定期进行安全性能检测,确保纺织品的安全性能符合国家标准。

纺织品的抗静电性能是衡量纺织品质量的重要指标之一,为了确保纺织品的抗静电性能符合国家标准,我们需要制定相应的标准并进行严格的质量控制,我们还需要不断进行技术创新和研发,提高纺织品的抗静电性能和品质,通过不断提高纺织品的抗静电性能和品质,我们可以为人们的生产生活环境提供更好的保障。

Articles related to the knowledge points of this article:

The Global Fabric of Bangladesh:An Overview of Dhaka International Textiles

Understanding the Differences between Textile Industry and Textile Products

The Role of Textile Printing Ponds in the Fabric Manufacturing Process