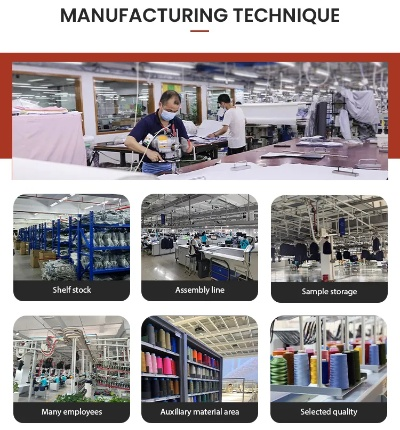

The Evolution of True Machine Textile Factory Innovations

The Evolution of True Machine Textile Factory Innovations,In the textile industry, true machine textile factories have undergone significant innovations in recent years. These innovations have led to increased efficiency, reduced labor costs, and improved product quality. Here are some key points:,1. Advanced Technology: The use of advanced technology, such as automation and robotics, has revolutionized the way textile factories operate. This technology has enabled factories to produce high-quality products at a faster pace than ever before.,2. Improved Processing: Advances in processing technology have also played a crucial role in the evolution of true machine textile factories. For example, the use of computer-controlled machinery has allowed factories to process materials more precisely and efficiently.,3. Increased Productivity: The adoption of advanced technology and improved processing methods has resulted in increased productivity for textile factories. This has allowed them to produce more products with less waste and lower labor costs.,4. Sustainable Practices: As the textile industry continues to evolve, so too must its practices. True machine textile factories are now adopting sustainable practices that reduce their environmental impact while still maintaining high levels of productivity.,Overall, the evolution of true machine textile factory innovations has had a significant impact on the industry, leading to increased efficiency, reduced labor costs, and improved product quality.

In the realm of textile manufacturing, the concept of a "True Machine" has revolutionized the industry. This term refers to machines that are designed to mimic human capabilities in terms of speed, precision, and consistency, making them an essential part of any modern textile factory. In this essay, we will explore the evolution of these innovative machines and how they have transformed the way we produce textiles.

At the heart of any true machine is its ability to process materials with unparalleled speed and accuracy. One such machine is the computer-controlled textile printing press. This revolutionary device uses advanced software to program the printing process, ensuring that every stitch is precisely placed on the fabric. By using this technology, manufacturers can produce high-quality garments with minimal waste and maximum efficiency.

Another example of a true machine is the automated weaving machine. This machine can work tirelessly for hours without needing breaks or rest, producing a seamless, even weave that is impossible to achieve with hand-loomed fabrics. This increased productivity has led to significant cost savings for both manufacturers and customers alike.

The use of robotic arms in textile factories has also seen significant growth in recent years. These machines are programmed to handle complex tasks such as cutting, sewing, and finishing, freeing up human workers to focus on more creative and technically demanding tasks. This automation has not only improved efficiency but also reduced errors and variability in production.

One area where true machines have made a significant impact is in the production of sustainable materials. The use of renewable energy sources and eco-friendly materials in textile production is becoming increasingly important as consumers become more conscious about their environmental impact. True machines equipped with advanced sensors and algorithms can monitor the production process in real-time, ensuring that materials are used efficiently and waste is minimized.

In addition to these technological advancements, there have also been significant improvements in the design and functionality of textile machinery. For example, newer models of printing presses are now equipped with UV curing technology, which allows for faster and more efficient dye application. Similarly, weaving machines now come equipped with sensors and other intelligent features that allow for real-time monitoring and adjustment of the weaving process.

One particularly noteworthy case study in the field of true machine innovation is the development of the first fully autonomous textile factory. This facility was built in China and employs over 1000 robots that perform a range of tasks from cutting to sewing to finishing. The benefits of this system are clear: increased productivity, reduced labor costs, and improved product quality. However, it also poses new challenges for manufacturers, including the need to invest in advanced training programs for their workforce and the potential for automation to lead to job displacement.

In conclusion, the development of true machines has had a profound impact on the textile industry. From improving production efficiency to promoting sustainability, these machines have opened up new possibilities for the future of textile manufacturing. As technology continues to advance, we can expect to see even more innovative solutions being developed to meet the needs of the rapidly changing market.

真机纺织厂是一个专注于生产高质量纺织品的企业,以其精湛的工艺、先进的设备和技术为特色,我们将深入了解这个企业的生产流程、产品特点以及其在行业中的地位。

生产流程

原料采集

真机纺织厂采用优质原料进行纺织生产,包括棉花、蚕丝、羊毛等,在原料采集过程中,企业注重环保和可持续性,采用环保采摘和有机种植方式,确保原料的质量和可持续性。

机械加工

真机纺织厂拥有先进的机械加工设备,包括织布机、染料染色机、印花机等,这些设备经过精心设计和优化,能够高效、准确地完成纺织品的加工和生产。

质量控制

真机纺织厂注重产品质量控制,采用严格的质量检测标准,在生产过程中,企业定期进行质量检测,确保每一步生产环节都符合质量标准,企业还建立了完善的退货和维修制度,确保产品质量稳定。

产品特点

高品质纺织品

真机纺织厂生产的纺织品具有高品质、高档次的特点,符合国内外市场的需求,其产品种类繁多,包括棉布、丝绸、羊毛织物等,深受消费者喜爱。

环保绿色纺织品

真机纺织厂注重环保和绿色生产,采用环保采摘和有机种植方式,确保原料的质量和可持续性,企业还注重产品的环保性能和绿色设计,推出了一系列环保绿色纺织品。

案例说明

以一家真机纺织厂为例,介绍其在行业中的地位和优势。

企业背景

该真机纺织厂是一家拥有多年经验的企业,拥有先进的设备和技术,专注于生产高质量纺织品,该企业在行业中具有较高的知名度和美誉度。

产品展示

该企业生产的纺织品种类繁多,包括棉布、丝绸、羊毛织物等,一款高品质的羊毛织物受到了消费者的热烈欢迎,该产品采用了先进的生产工艺和技术,具有柔软、舒适、保暖等特点,深受消费者喜爱,该企业还注重产品的环保性能和绿色设计,推出了一系列环保绿色纺织品。

真机纺织厂是一个专注于生产高质量纺织品的企业,以其精湛的工艺、先进的设备和技术为特色,在当今绿色环保的时代背景下,该企业注重环保和绿色生产,推动着纺织行业的发展,该企业还注重产品质量控制,不断提高产品的品质和档次,赢得了消费者的信赖和好评,在未来,真机纺织厂将继续致力于提高生产效率、降低成本、优化产品品质等方面的工作,为纺织行业的发展做出更大的贡献。

Articles related to the knowledge points of this article:

Top Textile Factories in Taizhou