The Art of Textile Treatment:A Comprehensive Guide to Finishing Techniques

Introduction: Textile treatments are the finishing processes applied to textile materials to enhance their appearance, functionality, and durability. From simple dyeing and printing to complex finishing methods such as embossing, padding, and coating, these techniques play a crucial role in shaping the final product. In this guide, we will explore various textile treatment techniques, including their applications, benefits, and considerations. Let's dive into the world of textile finishing!

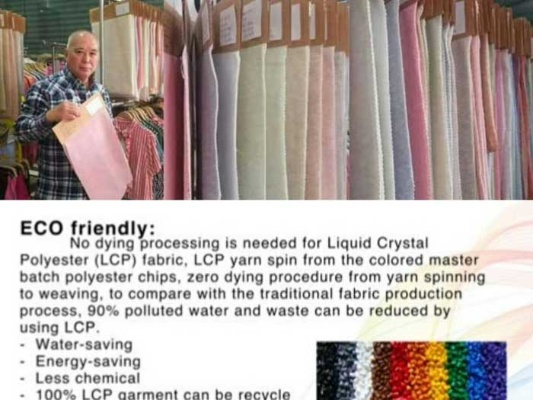

I. Dyeing and Printing

Basic Dyeing Techniques:

- Direct Dyeing: This method involves applying dye directly onto the fabric without pre-treatment. It is suitable for light colors and quick processing.

- Solvent Dyeing: This technique uses solvents like acetone or alcohol to dissolve the color into the fabric. It is effective for darker shades and produces glossier finishes.

- Emulsion Dyeing: This method involves using an emulsion containing dye and surfactants to penetrate the fabric fibers. It offers high-quality results and is commonly used for printed fabrics.

Advanced Dyeing Techniques:

- Embroidery Dyeing: This technique involves applying dye directly onto embroidered designs, resulting in intricate patterns that cannot be achieved with traditional dyeing methods.

- Screen Dyeing: This technique uses a screen to apply dye onto the fabric, creating a patterned finish. It is ideal for producing detailed designs and is commonly used in apparel and home decor.

Benefits:

- Enhanced Color Visibility: Dyeing and printing provide vibrant colors that are easy to see from a distance.

- Durability: These treatments can increase the lifespan of the fabric, making it more resistant to wear and tear.

- Customization: By choosing different dyeing and printing techniques, manufacturers can create unique and personalized products.

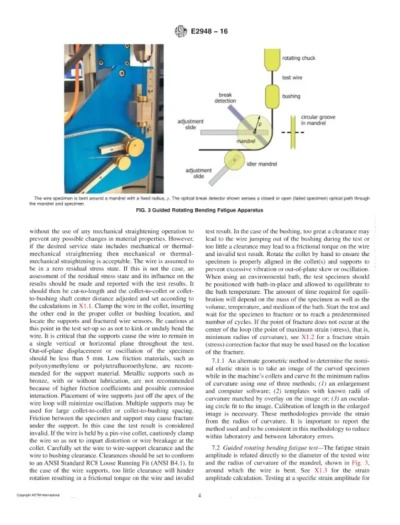

II. Embossing and Padding

Embossing Techniques:

- Stamp Embossing: This method involves pressing a stamp onto the fabric surface, which leaves an embossed impression. It is popular for creating textured effects on clothing and accessories.

- Die Embossing: This technique involves cutting out shapes from a die and pressing them onto the fabric, resulting in raised patterns. It is ideal for creating logos, patterns, and other decorative elements.

- Embossing Powder: This powder is applied to the fabric surface and then pressed into shape, resulting in a raised design. It is versatile and can be used for a variety of applications.

Benefits:

- Adds Texture: Embossing techniques add depth and texture to the fabric, making it more visually appealing.

- Enhances Durability: Embossed designs are more durable than plain fabrics and can withstand wear and tear better.

- Versatility: Embossing techniques can be used to create a wide range of designs, from geometric patterns to floral motifs.

III. Coatings and Stainless Steel Processes

Coating Techniques:

- Latex Coating: This method involves applying a latex solution to the fabric surface, which dries and forms a protective layer. It is commonly used for outdoor clothing and sportswear.

- Polyurethane Coating: This coating provides excellent durability, weather resistance, and flexibility. It is ideal for industrial applications and outdoor furniture.

- UV Resistant Coating: This coating protects the fabric against ultraviolet rays, which can fade and discolor fabrics over time. It is commonly used for outdoor clothing and upholstery.

Stainless Steel Processes:

- Chromium Plating: This process involves treating the fabric with chromium salts to achieve a smooth, shiny finish. It is popular for stainless steel hardware and jewelry.

- Nickel Plating: This process involves treating the fabric with nickel salts to achieve a bright, reflective finish. It is commonly used for stainless steel hardware and jewelry.

- Zinc Plating: This process involves treating the fabric with zinc salts to achieve a matte finish. It is commonly used for stainless steel hardware and jewelry.

Benefits:

- Protection Against Environmental Factors: Coatings and stainless steel processes provide a barrier against moisture, dust, and other environmental factors, extending the lifespan of the fabric.

- Durability: These treatments can increase the lifespan of the fabric, making it more resistant to wear and tear.

- Versatility: Coatings and stainless steel processes can be used to create a wide range of finishes, from classic matte finishes to modern shiny finishes.

IV. Conclusion:

Textile treatments are essential tools for creating beautiful and functional textile products. From basic dyeing and printing techniques to advanced embossing and coating processes, there are countless ways to transform fabric into something truly special. By understanding the benefits of each treatment method and selecting the appropriate technique for your specific application, you can create products that meet the needs of both consumers and industry professionals alike. So why not embrace the art of textile treatment and bring your ideas to life?

纺织品整理的重要性

在日常生活和商业活动中,纺织品的质量和外观直接影响到使用体验和品牌形象,纺织品整理是确保纺织品在使用过程中保持良好状态的关键步骤,它涉及到对纺织品进行清洁、消毒、整理和修复等操作,以提升其美观度、耐久性和功能性。

纺织品整理的步骤与技巧

准备工作

在进行纺织品整理之前,需要确保纺织品干净、无尘,并按照正确的顺序进行分类,需要准备好所需的整理工具和材料。

清洁

使用适当的清洁剂和清洁工具对纺织品进行清洁,去除表面的污垢、尘埃和油脂,清洁时应遵循一定的顺序和方法,避免损坏纺织品。

整理

根据纺织品的材质和设计特点,采用适当的整理方法,常见的整理方法包括平铺、卷曲、折叠、熨烫等,需要注意整理过程中的温度、湿度和压力等因素,以确保整理效果达到最佳。

修复

对于损坏的纺织品,需要进行修复,修复的方法包括修补破损区域、填补缝隙、更换损坏部件等,修复时应使用专业的修复工具和材料,以确保修复效果达到最佳。

案例分析:纺织品整理的实际应用

下面以一个具体的纺织品整理案例为例,来说明纺织品整理的实际应用。

案例:丝绸织物的整理

某品牌的一款丝绸织物在市场上备受青睐,为了保持其美观度和耐久性,该品牌对其进行了定期的整理,以下是该案例的详细步骤和技巧:

-

准备工作:将丝绸织物按照正确的顺序进行分类,准备好所需的整理工具和材料,需要确保工作环境干净、无尘。

-

清洁:使用温和的清洁剂对丝绸织物进行清洁,去除表面的污垢和尘埃,注意避免使用过于强烈的清洁剂,以免损坏丝绸织物。

-

整理:采用平铺的方法对丝绸织物进行整理,在整理过程中,需要注意温度、湿度和压力等因素,以确保整理效果达到最佳,可以使用柔软的整理剂来增强丝绸织物的柔软度和光泽度。

-

修复:对于丝绸织物上的破损区域,可以使用专业的修补工具进行修复,修复完成后,可以使用熨烫的方法来增强丝绸织物的平整度和光泽度,还可以定期使用保养剂来保持丝绸织物的健康状态。

英文表格说明(可选)

以下是一个英文表格,用于说明纺织品整理的相关信息:

| 步骤 | 描述 | 工具/材料 |

|---|---|---|

| 准备工作 | 确保纺织品干净、无尘 | 分类工具、清洁剂等 |

| 清洁 | 使用适当的清洁剂去除表面的污垢和尘埃 | 清洁剂等 |

| 整理 | 采用适当的整理方法(如平铺、卷曲等) | 整理工具等 |

| 修复 | 使用专业的修复工具进行修复 | 修复工具等 |

| 案例分析 | 丝绸织物整理的具体步骤和技巧 | 无具体案例数据 |

纺织品整理是确保纺织品在使用过程中保持良好状态的关键步骤,通过正确的整理方法和技巧,可以提升纺织品的外观和性能,提高使用体验和品牌形象,在实际应用中,需要根据纺织品的材质和设计特点选择合适的整理方法和技巧,并注意温度、湿度和压力等因素的影响。

Articles related to the knowledge points of this article:

Empowering Textiles:The Role of Enhancers in Zhejiang

Global Ranking of Textile Export Companies:A Comprehensive Analysis

Wynn Resorts Stunning Collections of Textile Designs

The Navigating Challenges of Applying for Jobs at Hangzhou Jiexi Ju Textiles