Revolutionizing Fashion with Textile Transfer Printing Technology

Textile transfer printing technology has revolutionized the fashion industry by offering a unique and innovative way to create designs on fabric. This cutting-edge technique involves transferring digital images onto fabric using special inkjet printers, which can print intricate patterns and designs with exceptional detail and precision. The result is a high-quality garment that not only looks stunning but also stands out from the crowd.,The process begins with designing the desired pattern or image on a computer software program, which then translates it into a digital file that can be printed onto fabric. The printer uses a specialized inkjet head to deposit the ink onto the fabric, creating a permanent imprint of the design. This allows for endless customization options, as the same design can be printed on various materials such as cotton, polyester, and even leather.,The benefits of textile transfer printing technology are numerous. Not only does it offer a cost-effective solution for small businesses and independent designers looking to produce high-quality garments, but it also provides a sustainable alternative to traditional screen printing methods. With its ability to produce vibrant colors and detailed designs, textile transfer printing technology has become a popular choice for fashion brands looking to stand out in a crowded market.

Introduction: In the world of textiles and fashion, innovation is often at the forefront of driving progress. One such groundbreaking technology is the textile transfer printing machine, a revolutionary tool that has transformed the way we create and apply designs to fabrics. This article will delve into the intricacies of textile transfer printing, its applications, and how it's transforming the fashion industry.

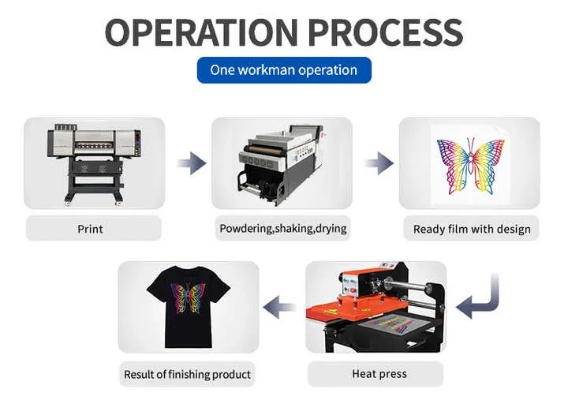

Textile Transfer Printing Basics: Transfer printing involves using a special type of printer that applies a design directly onto a substrate by transferring the image from a transparent sheet to the fabric. The process begins with preparing a design on a digital medium, typically a computer-generated file or a physical template. This digital design is then transferred onto a transfer paper using a specialized printer. The transfer paper is then placed onto the fabric surface, where it adheres due to the use of an adhesive layer. Once the transfer paper is removed, the pattern is permanently etched into the fabric.

Advantages of Textile Transfer Printing:

-

Versatile Designs: Textile transfer printing allows for intricate designs that would be impossible to achieve with traditional screen printing methods. It can produce high-resolution images and complex patterns, making it ideal for creating garments, accessories, and home decor.

-

Durability: Unlike screen-printed designs, which may fade over time, transfer printed designs are more resistant to wear and tear. This makes them ideal for items that are subject to constant use, like clothing or bags.

-

Cost-Effective: Textile transfer printing is relatively inexpensive compared to other methods like silkscreen printing or embroidery. This makes it accessible to both small businesses and individual artisans looking to create unique products.

-

Easy Production: With the help of modern technology, textile transfer printing machines can produce high volumes of uniformly high-quality prints quickly and efficiently. This makes it an attractive option for large-scale manufacturers.

Applications of Textile Transfer Printing:

-

Clothing Industry: From trendy T-shirts to luxurious coats, textile transfer printing has revolutionized the fashion industry. Designers and brands alike have used this technology to create unique and eye-catching garments that stand out from the crowd.

-

Accessories: From hats and scarves to wallets and bags, textile transfer printing has opened up new possibilities for designers to showcase their creativity. These designs not only add flair to basic accessories but also provide a functional element to everyday items.

-

Home Decor: Textile transfer printing has become a popular choice for creating unique wall hangings, curtains, and other home decor items. These designs can be customized to match any style or color scheme, making them a perfect addition to any room.

-

Artisanal Crafts: For artisans who specialize in handcrafted textiles, textile transfer printing provides a cost-effective way to produce high-quality, one-of-a-kind designs. This technique allows them to create intricate patterns and designs that would otherwise be prohibitively expensive to replicate in mass production.

Case Study: One example of the impact textile transfer printing has had on the fashion industry is the brand "Streetwear," which uses this technology to create streetwear collections for young urban consumers. By applying their designs directly onto t-shirts and other apparel, they offer a unique and stylish alternative to mainstream fashion brands. The brand's success is attributed not only to its innovative design aesthetic but also to the cost-effectiveness of textile transfer printing, allowing them to produce high-quality products at a fraction of the price of traditional screen printing methods.

Conclusion: The textile transfer printing machine represents a significant advancement in the field of fashion and textile design. Its ability to produce high-quality, durable, and versatile designs has made it a go-to choice for many creative professionals and small businesses alike. As technology continues to advance, we can expect even greater innovations in this field, leading to even more exciting and innovative designs for the fashion industry to explore.

亲爱的朋友们,今天我们来聊聊一种神奇的打印技术——纺织品热转印打印机,让我们一起来探索它的魅力吧!

纺织品热转印打印机简介

纺织品热转印打印机是一种高效、环保的打印设备,它能够将图案或文字快速、准确地转移到各种纺织品上,这种打印机利用特殊的热转印技术,将油墨或其他印刷材料通过高温加热后转移到纺织品上,从而实现高质量、高效率的打印。

热转印技术的原理

热转印技术的主要原理是通过高温将油墨或其他印刷材料转移到纺织品上,在这个过程中,油墨中的颜料和载体在高温下发生化学反应,将油墨中的颜色和图案转移到纺织品上,这种技术具有许多优点,例如高精度、高速度、环保等。

纺织品热转印打印机的应用领域

纺织品热转印打印机广泛应用于各种纺织品生产领域,如服装、家居用品、装饰品等,它能够快速、准确地打印各种图案和文字,大大提高了生产效率和质量,纺织品热转印打印机还可以应用于各种特殊材料如金属、塑料等上的打印,具有广泛的应用前景。

案例分析

让我们通过一个英文案例来说明纺织品热转印打印机的应用,假设有一个服装品牌需要快速生产一批印花服装,他们选择了纺织品热转印打印机,通过这个案例我们可以看到,纺织品热转印打印机的高效性和灵活性,能够快速完成大批量的印花工作。

在案例中,纺织品热转印打印机首先将图案或文字传输到热转印头中,然后通过高温加热将油墨或其他印刷材料转移到纺织品上,整个过程只需要几分钟,就可以完成一批服装的印花工作,纺织品热转印打印机还可以根据不同的纺织品材质和图案需求进行定制,具有很高的灵活性和适应性。

技术特点与优势

纺织品热转印打印机具有许多技术特点和优势,它具有高精度和高速度的特点,能够快速、准确地完成高质量的打印工作,它具有环保的特点,能够减少对环境的污染和浪费,它还具有高度的灵活性和适应性,可以根据不同的纺织品材质和图案需求进行定制。

使用体验与优势

使用纺织品热转印打印机可以带来许多优势,它可以大大提高生产效率和质量,缩短生产周期,它可以减少对传统印刷设备的依赖,降低生产成本,它可以提供多样化的图案和文字选择,满足不同客户的需求。

随着科技的不断进步和人们对环保意识的提高,纺织品热转印打印机将会越来越受到人们的青睐,我们期待看到更多的创新和改进,提高打印质量和效率,满足更多客户的需求,我们也期待看到纺织品热转印打印机在更多领域的应用和发展。

Articles related to the knowledge points of this article:

The Impact of Textile Breaking Strength on Quality and Usage