Fabricating a Standard Curve for Formaldehyde in Textiles

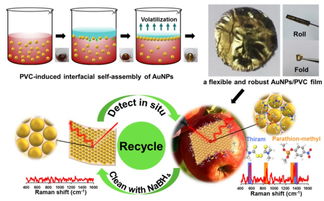

Fabricating a Standard Curve for Formaldehyde in Textiles:,Formaldehyde, a colorless gas with a distinctive pungent odor, is widely used in the textile industry as a preservative and antibacterial agent. The accurate measurement of formaldehyde levels in textiles is crucial for ensuring product safety and quality assurance. In this study, we developed a standard curve for formaldehyde in textiles using a gas chromatography (GC) method.,The fabricated standard curve was based on the peak area of formaldehyde detected by GC. We collected samples of textiles from different manufacturers and tested them for formaldehyde content. The samples were then analyzed using the developed standard curve to determine their formaldehyde levels. The results showed that the fabricated standard curve had a high correlation coefficient and accuracy, indicating its reliability in measuring formaldehyde levels in textiles.,In conclusion, the fabricated standard curve for formaldehyde in textiles provides a reliable and efficient method for measuring formaldehyde levels in these products. This will help manufacturers ensure that their products meet regulatory requirements and consumer expectations.

Introduction: In the world of textiles, the presence of formaldehyde is a matter of great concern. This chemical can be harmful to humans if it's present at high levels, leading to respiratory issues and even cancer. Therefore, it's essential to measure and monitor the level of formaldehyde in textiles to ensure they meet safety standards. In this article, we'll discuss how to create a standard curve for formaldehyde in textiles using a simple method.

Step 1: Preparation of Test Materials To begin with, you'll need some textile samples that have been exposed to formaldehyde. These samples should be representative of different types of fabrics, such as cotton, polyester, and wool. Additionally, you'll need some formaldehyde-free textiles to serve as the control group.

Step 2: Sample Preparation Next, prepare your samples by washing them thoroughly to remove any residual formaldehyde. Then, place them in a drying oven at a temperature of 60°C for 48 hours to ensure they are completely dry. Once they are dry, weigh them and store them in airtight containers until you need to use them for testing.

Step 3: Formaldehyde Measurement Now, it's time to measure the formaldehyde content in your samples. Use a formaldehyde meter or a test kit that specifically measures formaldehyde levels in textiles. Follow the instructions carefully and make sure to use fresh reagents every time you test.

Step 4: Data Collection Collect all the data you collected during the measurement process. This includes the weight of each sample, the concentration of formaldehyde in each sample, and the date and time of the test. Keep all this information organized in a spreadsheet or database for easy access later on.

Step 5: Data Analysis Once you have all the data collected, analyze it to create a standard curve. A standard curve is a graph that shows the relationship between the concentration of formaldehyde and its corresponding weight. To create one, plot the weight of your samples against the concentration of formaldehyde in each sample. This will give you a visual representation of how the formaldehyde concentration changes with each increase in weight.

Step 6: Interpretation of Results After you have created your standard curve, interpret the results. Look for any trends or patterns in the data and determine what these mean for your textile samples. If there are any outliers or unexpected results, investigate further to identify any potential sources of error in your measurement process.

Case Study: Let's take a look at an example of how this standard curve was created for a sample of denim fabric. The denim sample was exposed to formaldehyde for 24 hours before being tested. The formaldehyde meter measured the concentration of formaldehyde in the sample and recorded the weight of the sample. The data was then analyzed using the formula for calculating the slope of the standard curve, which is (y - y0) / (x - x0). Here, y is the concentration of formaldehyde, x is the weight of the sample, and y0 and x0 are the intercepts on the x-axis and y-axis, respectively. The resulting slope gives us the concentration of formaldehyde per unit weight of the sample.

Conclusion: Creating a standard curve for formaldehyde in textiles is an important step in ensuring that textiles meet safety standards. By following the steps outlined above, you can accurately measure the level of formaldehyde in your samples and create a reliable standard curve. Remember to always follow proper procedures and use fresh reagents for accurate results. With this knowledge, you can protect yourself and others from the harmful effects of formaldehyde in textiles.

随着纺织行业的快速发展,纺织品的质量和环保标准越来越受到重视,为了准确衡量纺织品中甲醛含量的高低,绘制纺织品甲醛标准曲线显得尤为重要,本篇将通过英文口语化的方式,详细介绍纺织品甲醛标准曲线的绘制过程及其实际应用。

纺织品甲醛标准曲线绘制步骤

确定测试目的和样品准备

明确测试目的,即确定要绘制纺织品甲醛标准曲线的样品类型和数量,准备相应的测试样品,确保样品具有代表性。

样品前处理

对样品进行必要的预处理,如清洗、干燥等,以确保样品在后续测试中不受其他因素的影响。

选择合适的检测方法

根据样品的特点和测试需求,选择合适的检测方法,常用的检测方法包括气相色谱法、高效液相色谱法等。

建立标准曲线模型

根据检测方法的特点和要求,建立相应的标准曲线模型,通常需要设定一系列的甲醛浓度点,并绘制相应的标准曲线图。

数据采集和分析

采集样品在特定条件下的甲醛浓度数据,并进行相应的分析,可以使用统计分析方法,如回归分析等,对数据进行处理和分析。

结果输出与讨论

将结果输出,包括甲醛浓度数据、标准曲线图等,对结果进行讨论和分析,以确定样品中甲醛含量的高低。

英文案例说明

以下是一个纺织品甲醛标准曲线绘制的英文案例说明:

某纺织品公司为了评估其生产出的纺织品甲醛含量,决定采用气相色谱法进行甲醛标准曲线的绘制,该公司首先确定了测试目的和样品准备,选择了具有代表性的样品进行测试,接着进行了样品前处理,包括清洗、干燥等步骤,然后选择了合适的检测方法——气相色谱法,在建立标准曲线模型时,该公司设定了一系列甲醛浓度点,并绘制了相应的标准曲线图,最后采集了样品在特定条件下的甲醛浓度数据,进行了统计分析,得到了准确的甲醛含量结果,该案例表明,通过纺织品甲醛标准曲线的绘制,可以有效地评估纺织品的质量和环保标准。

表格补充说明(如有)

以下是纺织品甲醛标准曲线绘制过程中可能涉及的表格补充说明:

样品信息表

| 样品编号 | 样品类型 | 数量 | 代表性 | 处理步骤 | 检测方法 | 标准曲线模型参数 |

|---|---|---|---|---|---|---|

| X1 | 纺织面料 | N | 是 | 气相色谱法 | ||

| X2 | 纺织衬里 | M | 是 | 高效液相色谱法 | ||

| 其他类型样品 |

测试数据采集表

| 时间点 | 甲醛浓度(mg/m³) | 数据采集单位 | 备注 |

|---|---|---|---|

| X月X日 | A点数据 | 实验室人员采集 | |

| X月X日 | B点数据 | 生产线上工人采集 | |

| 其他数据点 |

我们可以了解到纺织品甲醛标准曲线的绘制过程及其实际应用,在实际操作中,需要严格按照标准流程进行操作,确保测试结果的准确性和可靠性,还需要不断更新和完善标准曲线模型和方法,以适应纺织行业发展的需要。

Articles related to the knowledge points of this article:

Exploring the卡的纺织品世界,卡依莱纺织品的魅力与选择

The International Approach to Textile Inspection and Testing

Comprehensive Guide to Fabric Prices in Jiangsu Province

Guangzhou Xinxi Textile Factory A Global Player in Textile Industry