Textile Dyeing Knowledge and Its Applications

Dyeing is a crucial process in the textile industry, which involves applying colorants to fabrics to create patterns and enhance their aesthetic appeal. This article discusses the fundamental knowledge of textile dyeing, including the principles of dyeing, the different types of dyes used, and the methods of dyeing. It also explores the applications of textile dyeing, such as garment manufacturing, upholstery, and home furnishings. The article emphasizes the importance of choosing appropriate dyes for specific applications, considering factors like colorfastness, washability, and environmental impact. Additionally, it highlights the importance of using modern technology to improve dyeing efficiency and reduce waste. Overall, this article provides a comprehensive overview of textile dyeing knowledge and its various applications, offering valuable insights for those involved in the textile industry.

Introduction: Textile dyeing is a crucial process in the manufacturing of textile products, as it allows for the creation of unique colors and patterns that reflect the aesthetic appeal of clothing, home decor, and other textile materials. This session will explore the fundamental principles of textile dyeing, including the types of dyes used, the processes involved, and the challenges faced in achieving consistent results. Additionally, we will examine how dyeing techniques have evolved over time, as well as some innovative applications of modern dyeing technologies. By the end of this presentation, you will have a comprehensive understanding of the science behind textile dyeing and its practical applications.

Types of Dyes Used in Textile Dyeing: Textile dyes are classified into several categories based on their chemical makeup and color characteristics. The most common types of dyes used in textile dyeing include:

-

Acid Dyes: These dyes are derived from natural or synthetic sources and contain an acid group. They are commonly used for bright, vibrant colors and are effective at removing excess dye during washing.

-

Basic Dyes: These dyes are derived from natural or synthetic sources and contain a basic group. They are suitable for producing shades of red, blue, and green, and are often used in combination with acid dyes to achieve more complex color combinations.

-

Direct Dyes: These dyes are designed to be absorbed directly into fibers without the need for a preliminary fixation process. They are ideal for high-quality printing and patterning applications.

-

Emulsion Dyes: These dyes are dissolved in water and form an emulsion when applied to the fabric. They are widely used for industrial applications and can produce a wide range of colors.

Processes Involved in Textile Dyeing: The dyeing process involves several steps, each aimed at achieving the desired color and texture on the fabric. Here are the key steps involved in textile dyeing:

-

Pretreatment: Before applying the dye, the fabric undergoes a pretreatment step to remove any impurities or oils that could interfere with the dye's absorption. This may involve steaming, scouring, or using detergents.

-

Dyeing: The fabric is then immersed in the dye bath, which contains the dye and other chemicals designed to facilitate the absorption of the color. The duration and temperature of the dyeing process can vary depending on the type of dye and fabric being treated.

-

Rinsing: After the dyeing process, the fabric is rinsed thoroughly to remove any excess dye and any unevenly distributed dye.

-

Drying: Finally, the fabric is dried using various techniques such as air drying, oven drying, or machine drying.

Challenges Faced in Textile Dyeing: While textile dyeing has many benefits, there are also several challenges that must be overcome to ensure consistent results. Some of these challenges include:

-

Color Retention: One of the biggest challenges in textile dyeing is ensuring that the dye remains stable throughout the washing process. If the dye fades or bleeds, it can result in discolored or stained fabrics.

-

Stain Resistance: Another challenge is ensuring that the fabric is resistant to staining, especially when exposed to harsh chemicals or soils. This requires careful selection of dyes and treatment methods to minimize potential stain risks.

-

Environmental Impact: Finally, textile dyeing must be conducted in a way that minimizes its environmental impact. This includes reducing waste production, minimizing water usage, and using eco-friendly solvents and dyes.

Innovative Applications of Modern Dyeing Technologies: As technology advances, new dyeing technologies have emerged that offer improved efficiency, sustainability, and quality control. Here are a few examples:

-

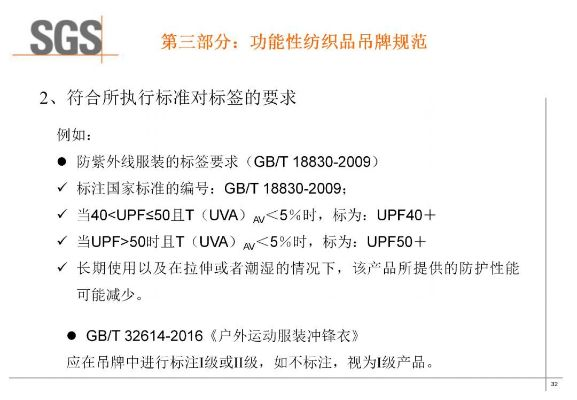

Smart Dyes: Smart dyes are designed to respond to specific wavelengths of light, enabling them to change color based on environmental conditions such as temperature or pH levels. This technology is particularly useful in creating customizable dye solutions that can adapt to different applications.

-

UV Curing: UV curing technology uses ultraviolet light to activate the dye molecules, allowing for faster and more efficient dye application. This method eliminates the need for heat and reduces energy consumption, making it an attractive option for industrial applications.

-

Bio-Based Dyes: Bio-based dyes are derived from renewable resources such as plant extracts or animal byproducts. These dyes are environmentally friendly and have been shown to have similar properties to conventional dyes while reducing negative impacts on the environment.

Conclusion: Textile dyeing is a complex process that requires careful consideration of various factors to achieve consistent results. From the types of dyes used to the challenges faced in dyeing, there is always room for improvement and innovation. With the advancements in technology, we can expect even greater precision and efficiency in our dyeing processes, ultimately leading to higher quality textile products that meet the needs of today's consumers.

纺织品染色是一门涉及多种技术和工艺的复杂工艺,它涉及到染料的选取、染色工艺的制定、染色设备的操作等多个方面,本文将详细介绍纺织品染色的知识点,并通过案例分析来加深理解。

染料基础知识

染料类型

染料是纺织品染色过程中的关键因素,根据不同的性能和应用领域,染料可分为活性染料、酸性染料、中性染料等,每种染料都有其独特的性质和应用范围。

染料选择

在选择染料时,需要考虑纤维材质、颜色要求、织物类型等因素,不同的纤维材质需要选择与之相容的染料,以达到最佳的染色效果,颜色要求也是选择染料的重要依据,以满足不同的使用需求。

染色工艺流程

前期准备

在染色前,需要进行准备工作,包括纤维准备、染缸准备、染料准备等,纤维准备包括对纤维进行预处理,使其达到最佳的染色效果,染缸准备则是为了确保染色过程中的温度、湿度等条件控制得当。

染色过程

染色过程主要包括浸染、加热、氧化、退色等步骤,浸染是将纤维放入染缸中,使其与染料充分接触并进行染色,加热是为了使染料更好地渗透到纤维中,氧化是为了使染料与纤维发生化学反应,达到更好的染色效果,最后是退色处理,去除多余的染料和色牢度不够的部分。

案例分析

以某纺织品公司的染色案例为例,详细说明纺织品染色的知识点。

纤维材质与选择染料

该公司的纺织品主要使用棉、涤纶等纤维材质,在选择染料时,考虑到棉纤维的天然颜色和涤纶的耐久性,选择了活性染料进行染色。

染色工艺流程

在染色过程中,首先对纤维进行预处理,确保其达到最佳的染色效果,然后进行浸染,将纤维放入染缸中,与染料充分接触并进行染色,接着进行加热处理,使染料更好地渗透到纤维中,最后进行氧化处理,进一步增强染色效果和色牢度,整个染色过程严格按照工艺流程进行操作。

结果展示

经过染色处理后,该公司的纺织品呈现出鲜艳的颜色和良好的色牢度,颜色均匀,质地柔软,深受消费者喜爱。

知识点总结

- 染料基础知识:了解不同类型染料的性质和应用领域,选择适合的染料进行染色,同时要考虑纤维材质、颜色要求等因素。

- 染色工艺流程:了解染色过程中的浸染、加热、氧化、退色等步骤,以及每个步骤的具体操作方法,同时要注意控制染色过程中的温度、湿度等条件。

- 案例分析:通过具体的案例分析,加深对纺织品染色知识点的理解和应用,同时可以借鉴成功案例中的经验和技巧,提高染色效果和质量。

纺织品染色是一门涉及多种技术和工艺的复杂工艺,需要掌握染料的选取、染色工艺的制定和染色设备的操作等多个方面的知识点,通过案例分析可以加深理解,提高染色效果和质量,在实际操作中,还需要注意控制染色过程中的温度、湿度等条件,以确保染色效果的最佳性。

Articles related to the knowledge points of this article:

纺织品欧盟Reach and ASTM Standards:A Comprehensive Guide for Manufacturers

Transformative Apparel:The American Retro Look in Fashion

Where to Find the Lowest-Priced Fabrics for Wholesale

The Global Industry Landscape of Textile Cable Manufacturing