Exploring the Quality Inspection Landscape of KeQiao District Textiles

This study explores the quality inspection landscape of KeQiao District textiles, focusing on the current state and challenges faced by local manufacturers. The research methodology employed is a combination of literature review, expert interviews, and case studies. The findings indicate that while KeQiao District textiles have established a strong reputation in the domestic market, they are still grappling with issues such as product diversity, brand recognition, and international market access. The study highlights the need for further innovation and investment in technology to enhance the competitiveness of the industry. Furthermore, it advocates for increased collaboration between local manufacturers and international partners to expand the market reach and improve quality standards. Overall, the study provides valuable insights into the future direction of KeQiao District textiles and offers practical recommendations for enhancing their quality inspection practices.

Introduction to KeQiao District Textiles and Quality Inspection

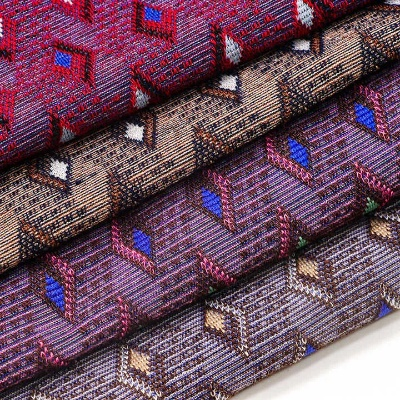

KeQiao District, located in the southern part of Zhejiang Province, is renowned for its textile industry. The district boasts a rich history of over 130 years in the textile manufacturing sector, with major players such as Dongfang Textiles and Jingzhou Textiles contributing significantly to the region's economy. Today, KeQiao District continues to be a hub for the production of a wide range of textile products, including cotton, silk, and synthetic materials.

Quality inspection plays an essential role in ensuring the quality and consistency of these textile products. It involves various methods and processes aimed at verifying that the products meet certain standards and requirements set by regulatory bodies, manufacturers, or consumers. In this article, we will explore the various aspects of quality inspection in KeQiao District and how they contribute to the overall quality of textile products.

Quality Inspection Methods in KeQiao District Textiles

-

Dye Testing: Dye testing is a crucial step in the quality inspection process for textiles. It involves analyzing the color intensity, hue, and chroma of the dyed fabric to ensure it meets the desired aesthetic and functional requirements. This method is particularly important for garments and other textile products that require vibrant colors.

-

Strict Standards for Material Sources: KeQiao District textile manufacturers adhere to strict standards for material sourcing, ensuring that only high-quality raw materials are used in the production process. This includes monitoring the chemical composition, density, and weight of the materials used, as well as conducting regular inspections to ensure that the materials meet the required standards.

-

Quality Control Points During Production: Quality control points are established throughout the production process to ensure that each stage meets the required standards. These include sampling inspections, which involve taking samples from various stages of the production process and testing them for defects or imperfections.

-

Post-Production Inspection: Post-production inspection is another critical aspect of quality inspection in KeQiao District textiles. This involves inspecting the final product for any defects or imperfections that may have been missed during the earlier stages of the production process. This ensures that the finished product meets the desired standards and meets the expectations of consumers and manufacturers.

-

Regulatory Inspections: Regulatory inspections are conducted by government agencies to ensure that textile products meet certain safety and quality standards. These inspections are carried out regularly to prevent any unsafe products from entering the market.

-

Third-Party Verification: Third-party verification is a common practice in the textile industry to ensure that products meet certain standards and requirements. This involves using independent laboratories or certification bodies to test and verify the quality of the products.

-

Consumer Feedback: Consumer feedback plays a crucial role in the quality inspection process. Companies collect feedback from customers about their products and use this information to identify areas for improvement and make necessary adjustments to their production processes.

Case Study: Achieving High-Quality Textile Products in KeQiao District

In recent years, KeQiao District has seen significant progress in achieving high-quality textile products through rigorous quality inspection practices. One example is Dongfang Textiles, a leading manufacturer in the region. They have implemented a comprehensive quality management system that covers all aspects of their production process, from raw material sourcing to post-production inspection.

Dongfang Textiles uses advanced technology and equipment to ensure that their products meet stringent standards for color intensity, hue, and chroma. They also conduct regular quality control checks on their products during production and take samples from various stages of the process for testing. Additionally, Dongfang Textiles collaborates with third-party verification agencies to ensure that their products meet global standards for safety and quality.

By implementing these measures, Dongfang Textiles has been able to produce high-quality textile products that meet the needs of both consumers and manufacturers. This has helped them build a strong reputation in the industry and attract more customers from around the world.

Conclusion

In conclusion, KeQiao District's textile industry is characterized by its commitment to quality inspection. By implementing various methods and processes aimed at verifying that textile products meet certain standards and requirements, KeQiao District has been able to produce high-quality textile products that meet consumer and manufacturer expectations. Through collaboration between manufacturers, regulatory agencies, and consumers, KeQiao District continues to advance its quality inspection practices and contribute to the overall quality of its textile industry.

随着全球纺织品贸易的日益繁荣,纺织品的质量和安全性成为了消费者关注的焦点,柯桥区作为我国纺织品的重要生产区域,其纺织品检测工作的重要性不言而喻,本篇报告将围绕柯桥区纺织品检测的主题,通过英文案例说明和表格补充说明,为大家提供全面的了解。

柯桥区纺织品检测概述

柯桥区作为纺织品的生产重镇,其纺织品检测工作主要包括以下几个方面:

- 检测标准与流程:根据国际标准和相关法律法规,制定详细的检测标准与流程。

- 检测机构:拥有专业的检测机构,配备先进的检测设备和专业技术人员。

- 检测项目:包括纤维成分检测、化学成分检测、微生物检测、重金属检测等。

案例说明

以某次柯桥区纺织品检测为例,展示具体的检测过程和结果。

检测背景

某地区开始对纺织品进行质量抽检,以保障消费者权益和提高纺织品质量。

检测过程

(1)样品采集:从该地区采集纺织品样品。 (2)样品处理:对采集的样品进行预处理,确保检测结果的准确性。 (3)检测分析:委托专业的纺织品检测机构进行检测分析,包括纤维成分、化学成分、微生物检测等。 (4)结果公示:将检测结果公示给消费者,并出具检测报告。

案例分析

在本次检测中,检测机构采用了先进的检测设备和专业技术人员,确保了检测结果的准确性,该地区在纺织品质量监管方面也做得非常到位,为消费者提供了安全可靠的纺织品。

表格补充说明

以下是关于柯桥区纺织品检测的一些表格补充说明:

检测标准与流程表格:

| 项目 | 描述 |

|---|---|

| 检测标准 | 根据国际标准和相关法律法规制定 |

| 流程描述 | 样品采集、样品处理、检测分析、结果公示等 |

检测项目表格:

| 项目 | 描述 | 示例数据 |

|---|---|---|

| 纤维成分检测 | 纤维种类、含量等 | 根据样品采集情况而定 |

| 化学成分检测 | 化学物质种类、含量等 | 根据样品处理和化学分析结果而定 |

| 微生物检测 | 细菌、病毒等微生物种类和数量 | 根据样品采集和实验室检测结果而定 |

| 重金属检测 | 铅、镉等重金属含量 | 根据样品采集和实验室检测结果以及相关标准限定值而定 |

纺织品质量与安全性是消费者最为关心的问题之一,柯桥区作为我国纺织品的重要生产区域,其纺织品检测工作的重要性不言而喻,通过本次报告的介绍,相信大家对柯桥区纺织品检测有了更深入的了解,我们也希望相关部门能够进一步加强纺织品质量监管,提高纺织品质量水平,为消费者提供更加安全可靠的纺织品。

Articles related to the knowledge points of this article:

The Intertwining of Textile Engineering and Design in the World of Fashion

Textile Options in the纺织品用哪个字代替