The Role of Fire-Resistant Treatments in Wood and Textiles

Fire-resistant treatments are essential in enhancing the durability and safety of wood and textiles against fire damage. These treatments involve the application of chemicals or physical processes to the material, which enhance its ability to resist combustion. In wood, these treatments include coatings, impregnations, and treatments such as melamine formaldehyde resin (MFR) and phenolic resin. For textiles, flame retardants, acrylic resins, and other chemical additives are used. These treatments not only protect the material from fire but also improve its strength, flexibility, and resistance to wear and tear. The effectiveness of these treatments depends on the specific application and material being treated. Overall, fire-resistant treatments play a crucial role in protecting both wood and textiles from fire damage and ensuring their longevity and safety.

Introduction

Fire is a pervasive threat to human life and property. In the face of this danger, fire-resistant treatments have emerged as crucial tools for safeguarding both wood and textile materials. These treatments enhance the inherent flame retardancy of these materials, reducing the risk of combustion and spreading of fire. This article will explore the different types of fire-resistant treatments available for wood and textiles, their benefits, and how they are applied. We'll also provide an example of a successful application of fire-resistant treatments in the real world.

Types of Fire-Resistant Treatments

-

Chemical Treatments Chemical treatments involve the use of chemicals that react with the material during or after exposure to heat. These reactions can either delay or halt the combustion process. Some common chemicals used in chemical treatments include boron fluoride, phosphorus compounds, and silicone resins.

-

Physical Treatments Physical treatments involve altering the structure of the material itself to make it more resistant to fire. This can be achieved through techniques such as sanding, polishing, or coating the surface with a protective layer.

-

Intrinsic Flame Retardants Intrinsic flame retardants are incorporated into the material during its manufacturing process. They work by forming a barrier on the surface of the material that prevents the formation of a fuel/oxygen mixture necessary for combustion. Examples of intrinsic flame retardants include polyhedral oligomeric silsesquioxane (POSS) and melamine formaldehyde resin (MF) systems.

Benefits of Fire-Resistant Treatments

The primary advantage of fire-resistant treatments is their ability to significantly reduce the risk of fire spread and damage. By making materials more resistant to fire, these treatments help to protect people from potential harm and minimize property loss. Additionally, fire-resistant treatments can improve the durability and longevity of materials, extending their useful lifespan.

Application of Fire-Resistant Treatments

One successful application of fire-resistant treatments in the real world is found in the construction industry. For example, many high-rise buildings in developed countries use treated wood for structural elements due to its enhanced resistance to fire. Similarly, in the textile industry, fire-resistant treatments are commonly used in clothing, carpets, and upholstery to ensure that they can withstand high temperatures without burning or catching fire.

In the case of furniture, some manufacturers opt for treated wood or fabrics that have been treated with flame retardants to meet safety standards. These treatments not only enhance the material's fire resistance but also improve its appearance and comfort properties.

Conclusion

The implementation of fire-resistant treatments has become increasingly important in today's world, particularly in industries like construction and textiles. By enhancing the flame retardancy of materials, we can significantly reduce the risk of fire and minimize the damage caused by fires. As technology continues to advance, we can expect to see even more innovative applications of fire-resistant treatments in various fields.

随着人们对环保和安全的需求日益增长,木材和纺织品在日常生活和工业生产中的应用越来越广泛,为了满足这些需求,对木材和纺织品的阻燃处理变得尤为重要,本文将围绕阻燃处理木材和纺织品展开讨论,并介绍相关的技术和案例。

木材的阻燃处理

阻燃原理

木材的阻燃处理主要涉及到添加阻燃剂或采用特殊的阻燃处理方法,这些方法旨在降低木材在燃烧过程中产生的有毒烟雾和气体,同时保持木材的物理和机械性能,常见的阻燃剂包括卤化物、氮化物等。

案例分析

以某大型木材加工企业为例,该企业采用先进的阻燃技术对木材进行处理,该企业采用了先进的阻燃剂配方,通过添加适量的阻燃剂到木材中,实现了木材的高效阻燃,该企业还采用了特殊的阻燃处理方法,如热处理、辐射处理等,以提高木材的阻燃效果,经过处理后的木材不仅具有优良的物理和机械性能,而且具有较低的燃烧风险和烟雾排放。

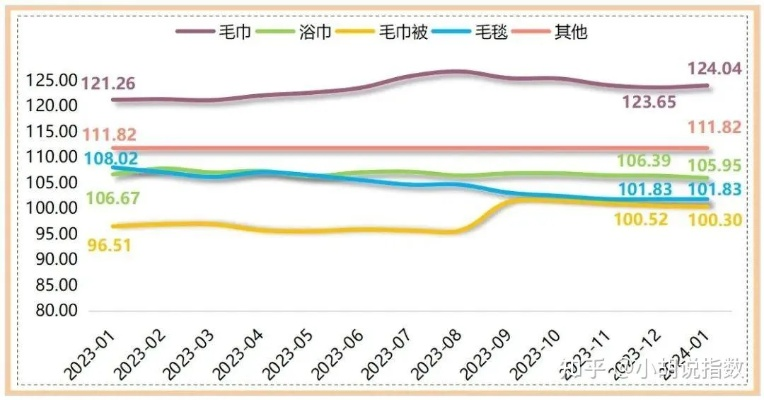

纺织品的阻燃处理

纺织品的阻燃处理技术

纺织品的阻燃处理主要涉及到添加阻燃剂或采用特殊的阻燃处理方法,这些方法旨在降低纺织品在燃烧过程中产生的有毒烟雾和气体,同时保持纺织品的舒适性和美观性,常见的纺织品的阻燃剂包括有机磷化合物、卤化物等。

案例分析

以某知名纺织品品牌为例,该品牌采用先进的阻燃技术对纺织品进行处理,该品牌采用了先进的阻燃剂配方,通过添加适量的阻燃剂到纺织品纤维中,实现了纺织品的高效阻燃,该品牌还采用了特殊的环保染料和工艺,以减少纺织品在燃烧过程中的有害物质排放,该品牌还注重环保和可持续性,采用环保材料和技术进行生产,从而降低了对环境的影响。

技术与案例说明

在木材和纺织品阻燃处理中,技术主要包括添加阻燃剂、采用特殊的阻燃处理方法等,以下是一些具体的技术和案例说明:

添加阻燃剂

添加阻燃剂是木材和纺织品阻燃处理的主要方法之一,常见的阻燃剂包括卤化物、氮化物等,这些阻燃剂可以与木材或纺织品的纤维结合,形成稳定的化合物,从而降低木材或纺织品的燃烧风险和烟雾排放,某大型木材加工企业采用了先进的阻燃剂配方,通过添加适量的阻燃剂到木材中,实现了木材的高效阻燃。

采用特殊的阻燃处理方法

采用特殊的阻燃处理方法可以提高木材和纺织品的阻燃效果,常见的处理方法包括热处理、辐射处理等,热处理是通过高温处理木材或纺织品纤维,使其达到一定的软化状态,从而降低其燃烧风险和烟雾排放,辐射处理则是利用辐射能量来破坏木材或纺织品的分子结构,使其难以燃烧,某知名纺织品品牌采用了先进的环保染料和工艺,通过特殊的环保染料和工艺来减少纺织品在燃烧过程中的有害物质排放,该品牌还注重环保和可持续性,采用环保材料和技术进行生产,从而降低了对环境的影响。

阻燃处理木材和纺织品对于提高产品的安全性和环保性具有重要意义,在技术方面,添加阻燃剂、采用特殊的阻燃处理方法等是常用的方法,在案例方面,一些知名企业和品牌已经取得了显著的成果和经验,随着科技的不断发展和应用,相信更多的技术和案例将会涌现出来,为人们提供更多的选择和解决方案。

Articles related to the knowledge points of this article:

The Story of XiAn Citys New Districts黛美丝纺织品批发部

Luxurious and Durable:A Look Inside Lishen Shaoqian Textile Store

The Dynamism of Dalian Textile Trade Companys Global Reach