The Role of Cleaning Equipment in Textile Mills:A Comprehensive Guide

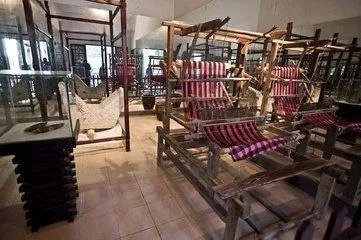

: The Role of Cleaning Equipment in Textile Mills: A Comprehensive Guide,Introduction:,Textile mills are essential industrial hubs that play a crucial role in the global textile industry. These mills process raw materials into fabric, yarn, and other textile products. However, the quality of these products relies heavily on the cleaning equipment used in the textile mills. This guide provides an overview of the different types of cleaning equipment used in textile mills and their roles in maintaining the cleanliness and efficiency of these facilities.,Types of Cleaning Equipment:,1. Vacuum Cleaners: These machines use suction to remove dirt and debris from surfaces. They are commonly used in textile mills for removing dust and oil stains.,2. Brooms and Sweepers: These tools are used to sweep and mop floors, eliminating dirt and debris. They are essential for maintaining clean and hygienic work environments.,3. Dust Collectors: These devices capture airborne particles and dust, reducing the risk of contamination and improving indoor air quality.,4. Scrubbers: These machines use abrasive materials to remove tough stains and grime from surfaces. They are commonly used in textile mills for cleaning machinery parts and equipment.,5. Pressure Washers: These machines use high-pressure water jets to remove stubborn stains and grime from surfaces. They are commonly used in textile mills for cleaning outdoor areas and machinery exteriors.,Conclusion:,The proper use and maintenance of cleaning equipment in textile mills is essential for maintaining cleanliness and productivity. By understanding the different types of cleaning equipment available and their roles, textile mill operators can ensure that their facilities remain clean and efficient.

Introduction: In the textile industry, cleanliness is not just a concern; it's a necessity. The textile mills are notorious for their dusty environments and high levels of contaminants that can pose serious health risks to workers. Therefore, the use of cleaning equipment has become an integral part of maintaining a hygienic working environment. In this guide, we will explore the importance of cleaning equipment in textile mills, its various types, and how they contribute to the overall productivity and safety of the industry.

Types of Cleaning Equipment in Textile Mills:

-

Vacuum Cleaners: These machines are designed to remove dust particles from surfaces by suction. They are commonly used in areas like warehouses, storage rooms, and production lines.

-

Sweepers: These devices are used to clean floors and other hard surfaces. They come in different shapes and sizes depending on the specific requirements of the textile mill.

-

Mops and Towels: These tools are used for floor cleaning and sanitation. They help in removing dirt, grime, and other contaminants from the floor.

-

Brooms and Rakes: These tools are used for sweeping and collecting debris from the floor. They are essential in keeping the floors clean and free from dust accumulation.

-

Scrubbing Pads and Blades: These tools are used for scrubbing and polishing surfaces. They are particularly useful in removing stains and disinfecting surfaces.

-

Microfiber Cloths: These cloths are made up of tiny fibers that trap dirt and dust particles. They are effective in removing fine dust and microorganisms.

-

Dust Trays and Filters: These tools are used to capture dust particles from the air. They help in reducing the amount of dust that reaches the worker's respiratory system.

-

Disinfectant Sprayers: These devices are used to spray chemicals onto surfaces to kill bacteria and viruses. They are crucial in ensuring the cleanliness of workstations and equipment.

-

Soft-Bristle Brushes: These brushes are used for cleaning delicate or fragile objects. They are gentle on the surface and do not damage the item being cleaned.

-

Steam Cleaners: These tools use hot steam to loosen up dirt and grime from surfaces. They are particularly effective in removing tough stains and odors.

Benefits of Using Cleaning Equipment in Textile Mills:

-

Improved Workplace Hygiene: By using cleaning equipment, textile mills can significantly reduce the amount of dust and contaminants in the workplace. This helps in maintaining a healthy working environment, which reduces the risk of respiratory diseases among workers.

-

Enhanced Product Quality: Cleanliness plays a crucial role in the quality of textile products. By using cleaning equipment, textile mills can produce higher-quality fabrics and garments with fewer defects.

-

Increased Productivity: A clean and organized work environment can improve productivity. Employees can focus more on their tasks without worrying about the mess around them, leading to increased output and efficiency.

-

Cost Savings: Proper maintenance of cleaning equipment can save money in the long run. Regular cleaning and repair of equipment can prevent breakdowns and costly replacements, reducing expenses.

-

Environmental Conservation: Textile mills have a significant impact on the environment due to their extensive use of water, energy, and chemicals. By using cleaning equipment, textile mills can minimize their environmental footprint and contribute to sustainable development.

Case Study: XYZ Textile Mills, located in Chennai, India, has been using cleaning equipment for over a decade. The company employs a team of 100 employees and operates a large-scale textile plant. The mill produces a variety of fabrics for various industries, including apparel, home furnishings, and sportswear.

To maintain the cleanliness of their facility, XYZ Textile Mills invests heavily in cleaning equipment. They have installed several vacuum cleaners, mops, and brooms in different parts of the plant. The mops and brooms are regularly replaced to ensure that they remain effective in removing dirt and dust.

The company also uses a range of scrubbing pads and blades for cleaning machinery and equipment. These tools help in removing rust and stains from the machinery, preventing them from affecting the quality of the fabric produced.

Moreover, XYZ Textile Mills has implemented a strict policy on waste disposal. They have designated areas for recycling and disposal of hazardous materials, such as solvents and chemicals. The company also conducts regular training sessions for their employees on proper waste management practices.

As a result of these efforts, XYZ Textile Mills has achieved excellent customer satisfaction ratings and reduced the incidence of illnesses among employees. The company has also received several awards for its commitment to sustainability and environmental conservation.

Conclusion: In conclusion, the use of cleaning equipment in textile mills is crucial for maintaining a healthy and productive work environment. It helps in improving product quality, increasing productivity, saving costs, and conserving the environment. As seen in the case study, XYZ Textile Mills has successfully implemented a comprehensive cleaning strategy that has resulted in positive outcomes for both the company and its employees. Therefore, it is essential for textile mills to invest in cleaning equipment to enhance their operations and contribute to sustainable development.

纺织厂清洁设备概述

在繁忙的纺织厂中,清洁设备扮演着至关重要的角色,这些设备不仅确保了生产环境的整洁和卫生,还提高了生产效率和质量,本文将详细介绍纺织厂清洁设备的种类、功能及其在实践中的应用。

纺织厂清洁设备种类

- 吸尘器:吸尘器是纺织厂中常用的清洁设备之一,它能够有效地清除生产过程中的尘埃、纤维碎屑等杂质,保持生产环境的清洁。

- 清洗机:清洗机主要用于清洗各种纺织材料,包括棉、麻、丝等,它能有效地去除材料表面的污渍和残留物,提高材料的清洁度和质量。

- 消毒设备:消毒设备主要用于对纺织生产过程中的设备和工具进行消毒,防止细菌和病毒的传播,常见的消毒设备包括紫外线消毒器和高温消毒器。

- 除尘设备:除尘设备主要用于清除生产过程中的粉尘和烟雾,保证生产环境的空气质量,常见的除尘设备包括静电除尘器和湿式除尘器。

纺织厂清洁设备功能

- 高效清洁:吸尘器能够快速清除生产过程中的尘埃和杂质,保持生产环境的清洁,清洗机能够有效地清洗各种纺织材料,提高材料的清洁度和质量。

- 预防污染:消毒设备能够有效地杀灭细菌和病毒,防止生产过程中的污染,除尘设备能够清除生产过程中的粉尘和烟雾,保证生产环境的空气质量。

- 提高效率:清洁设备的合理使用可以提高纺织厂的运营效率,吸尘器可以定期进行深度清洁和维护,延长设备的使用寿命。

案例分析

以某纺织厂为例,该厂采用了多种清洁设备来提高生产效率和清洁度。

- 吸尘器:该厂采用了吸尘器来清除生产过程中的尘埃和杂质,吸尘器不仅可以清除地面上的尘埃,还可以清除设备上的灰尘和碎屑,这种设备的维护和保养非常简单,只需要定期进行深度清洁和维护即可。

- 清洗机:该厂采用了先进的清洗机来清洗各种纺织材料,清洗机能够有效地去除材料表面的污渍和残留物,提高材料的清洁度和质量,该清洗机还具有自动清洗和智能控制功能,可以根据不同的材料和工艺需求进行自动调整。

- 消毒设备:该厂采用了紫外线消毒器和高温消毒器来对纺织生产过程中的设备和工具进行消毒,这种消毒设备的操作简单方便,只需要按照设定的程序进行操作即可,该消毒设备还可以杀灭细菌和病毒,防止生产过程中的污染。

纺织厂清洁设备的种类繁多,功能各异,在实践应用中,需要根据不同的设备和工艺需求选择合适的清洁设备,还需要注重清洁设备的合理使用和维护保养,以保证生产环境的清洁度和质量,还需要加强员工的培训和管理,提高员工的清洁意识和操作技能,从而更好地发挥清洁设备的功效。

Articles related to the knowledge points of this article:

The Height of Yangs Textile Factory

The Textile Factorys Digital Modeling Journey

The Story of Dongguan Jiangnan Textile Factory