Essential Elements of Textile Product Quality Testing

Textile product quality testing is a crucial aspect of ensuring the safety, durability, and aesthetic appeal of textiles. The essential elements of this testing include:,1. Material selection: The selection of materials for textile products is critical as it directly impacts their performance and longevity. Materials such as cotton, polyester, and wool are commonly used in textile products.,2. Quality control: Quality control measures must be implemented to ensure that the raw materials used in the production process meet the required standards. This includes monitoring the quality of the raw materials, the quality of the finished products, and the quality of the manufacturing processes.,3. Testing methods: There are various testing methods used in textile product quality testing, including mechanical testing, chemical testing, and visual inspection. These methods help identify any flaws or defects in the textile products.,4. Data analysis: The data collected from the testing methods must be analyzed to determine any potential issues with the textile products. This analysis helps identify areas where improvements can be made to enhance the quality of the products.,In conclusion, textile product quality testing is essential for ensuring the safety, durability, and aesthetic appeal of textile products. By implementing quality control measures, using appropriate testing methods, and analyzing the data obtained, manufacturers can produce high-quality textile products that meet consumer expectations.

Introduction to Textile Testing Textile products have become an integral part of our daily lives, from clothing and household items to industrial fabrics. As such, the importance of ensuring that these products meet high standards of quality cannot be overstated. Textile testing is a critical process that ensures the safety, durability, and aesthetic appeal of textile goods. In this article, we will discuss the essential elements of textile product testing, including the various types of tests, their purposes, and how they contribute to the overall quality of textile products.

Types of Textile Testing There are several types of textile testing that aim to evaluate the properties of textile materials, including:

-

Material Testing: This involves assessing the physical and chemical properties of raw materials used in textile production. For example, the strength and elasticity of yarns, the dyeability and washfastness of fabrics, and the moisture absorption capacity of fibers are all material-related properties that need to be tested to ensure consistent quality across different batches.

-

Process Testing: This type of testing focuses on evaluating the performance of the entire textile production process, from raw material procurement to final product assembly. Common processes tested include dyeing, printing, weaving, and finishing. These tests help identify any defects or issues during the manufacturing process that could affect the quality of the final product.

-

End-Use Testing: This involves examining the performance of textile products under real-world conditions, such as wear and tear, handling, and exposure to different environments. End-use testing helps determine whether the product meets the expected performance criteria and can withstand the challenges it may face in its intended use.

-

Environmental Testing: As concerns about sustainability and environmental impact grow, there has been a growing demand for testing textile products to ensure they do not harm the environment during their life cycle. This includes testing for toxic substances, biodegradability, and energy efficiency.

Purposes of Textile Testing The primary purpose of textile testing is to ensure that products meet regulatory requirements and consumer expectations. By conducting thorough testing, manufacturers can identify any potential defects or flaws in their products early on in the production process, allowing them to make necessary adjustments before shipping or delivering the product to customers. Additionally, textile testing helps prevent costly recalls and legal disputes caused by defective products.

Effective Textile Testing Practices To achieve optimal results from textile testing, manufacturers must adhere to strict guidelines and protocols. Here are some key practices that can enhance the effectiveness of textile testing:

-

Standardized Testing Procedures: Companies should establish clear and standardized testing procedures that cover all aspects of the textile product's lifecycle. This ensures consistency in testing methods and minimizes variability in results.

-

Continuous Quality Control: Regular inspections and testing should be conducted throughout the production process to catch any issues early and prevent them from escalating into more significant problems.

-

Data Analysis and Reporting: Companies should collect and analyze test data effectively to identify trends and patterns that can inform future product development and quality control strategies.

-

Collaboration with Third-Party Testing Agencies: Working with experienced third-party testing organizations can provide valuable insights into market trends and regulatory requirements, as well as offer expertise in specialized testing techniques.

-

Training and Education: Employees should receive regular training on new testing methods, industry best practices, and regulatory updates to ensure they are up-to-date with the latest standards and best practices in textile testing.

Examples of Textile Testing Case Studies To illustrate the practical application of textile testing, let's consider two case studies:

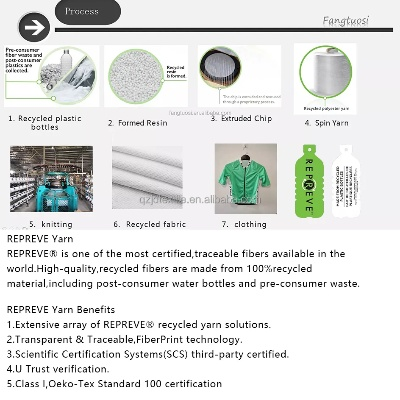

Case Study 1: New Fabric Launch A textile company launched a new line of eco-friendly fabrics aimed at reducing water pollution and promoting sustainable fashion. To ensure the quality of these fabrics met consumer expectations, the company conducted rigorous testing on the raw materials and finished products. The testing included material testing for color stability, dyeability, and moisture absorption; process testing for dyeing and finishing techniques; and end-use testing for comfort, durability, and environmental impact. The results were instrumental in guiding the company's design decisions and production processes, ultimately leading to a successful launch of the new fabric line.

Case Study 2: Recall Due to Defects A manufacturer of sportswear faced a recall after discovering that some of its products had defects that could pose a choking hazard. The company's textile testing department identified a flaw in the knitting process that led to loose threads. Upon learning of this issue, the company immediately halted production and conducted further testing to identify other similar products that might be affected. Following these tests, the company decided to recall all affected products and implement corrective measures to prevent future occurrences. This incident highlighted the importance of thorough testing in identifying and addressing potential defects early in the production process.

Conclusion Textile testing is a crucial aspect of ensuring the quality and safety of textile products. By adhering to standardized testing procedures, implementing continuous quality control measures, and collaborating with third-party testing agencies, companies can improve their product quality and customer satisfaction. Additionally, effective training and education programs can empower employees to stay up-to-date with industry advancements and best practices in textile testing. As consumers become more aware of the environmental impact of textile products, the importance of responsible testing practices will only continue to grow.

纺织品检验考试培训概述

随着纺织行业的快速发展,纺织品检验考试培训的重要性日益凸显,本培训旨在为纺织品检验人员提供全面、系统的考试培训,帮助他们掌握最新的检验标准和技巧,提高检验效率和质量。 与目标

- 纺织品基础知识:介绍纺织品的基本概念、分类及其在纺织行业中的应用。

- 检验标准与流程:详细讲解纺织品检验的各项标准与流程,包括纤维含量检测、织物结构检测、色牢度检测等。

- 检验技能培训:针对不同检验项目,提供实际操作技能培训,包括样品采集、实验操作、数据分析等。

- 案例分析:通过实际案例分析,让学员了解纺织品检验的实际操作和注意事项。

培训方法与手段

- 理论讲解:通过授课、案例分析等形式,向学员介绍纺织品检验的相关知识。

- 实践操作:组织学员进行实际操作练习,让他们掌握检验技能。

- 模拟考试:组织模拟考试,检验学员的学习效果。

- 专家指导:邀请行业专家进行现场指导,解答学员疑问。

培训效果评估

- 学员反馈:通过问卷调查等方式,收集学员对培训效果的反馈。

- 考试成绩:对学员进行考试考核,评估培训效果。

- 案例分析报告:对实际案例进行分析,总结经验教训。

- 行业认可度:通过行业认可度测试等方式,提高培训效果和影响力。

培训案例说明

纤维含量检测培训

在纤维含量检测培训中,我们组织了学员参观纤维加工生产线,了解纤维的种类和来源,邀请行业专家进行现场指导,讲解纤维含量检测的标准和流程,通过实际操作练习,学员掌握了纤维含量检测的操作技能,提高了检测效率和质量。

织物结构检测培训

在织物结构检测培训中,我们组织了学员参观织物生产车间,了解织物的生产工艺和质量控制,邀请专业技术人员讲解织物结构检测的标准和流程,并提供实际操作技能培训,通过实际操作练习,学员掌握了织物结构检测的操作技能,提高了检验精度和准确性。

总结与展望

本纺织品检验考试培训旨在提高纺织品检验人员的专业素质和检验效率,为纺织行业的发展提供有力支持,我们将继续加强培训力度,提高培训效果和影响力,为纺织行业的健康发展做出更大的贡献。

Articles related to the knowledge points of this article:

The Status of Ningde Textiles:A Look at Market Changes and Case Studies