The Dynamics of Bin Xin Textile Factory:An Overview

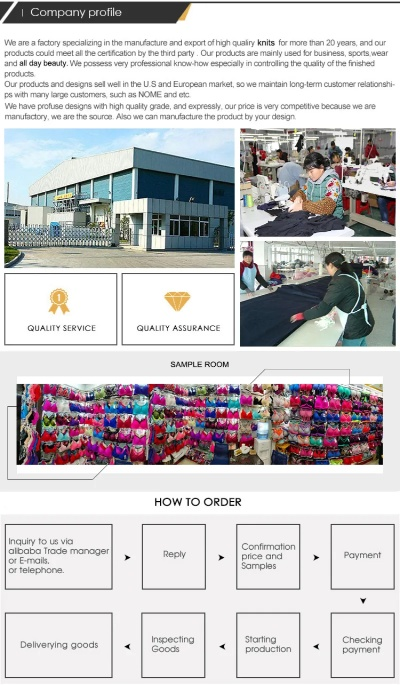

Bin Xin Textile Factory, located in the vibrant city of Hangzhou, is a leading manufacturer of high-quality textile products. This factory has been operating since 1995 and employs over 2000 people. The company's success can be attributed to its commitment to innovation, quality, and customer satisfaction.,One of the key factors that contribute to Bin Xin's success is its focus on innovation. The factory invests heavily in research and development, constantly exploring new technologies and materials to improve its products. This has led to the creation of a range of innovative textiles, including eco-friendly fabrics and sustainable materials.,In addition to innovation, Bin Xin also prioritizes quality control throughout the production process. Every step of the manufacturing process is carefully monitored to ensure that the final product meets or exceeds industry standards. This dedication to quality has earned the factory a reputation for producing high-quality textiles that are both durable and stylish.,Finally, Bin Xin places a strong emphasis on customer satisfaction. The factory offers a wide range of services, including customization, design consultation, and after-sales support, to help customers find the perfect textile solution for their needs. This attention to detail and personalized service has helped the factory build a loyal customer base and maintain a competitive edge in the market.

Introduction: The textile industry, a pillar of the global economy, is constantly evolving with new technologies and consumer preferences. One such dynamic player in this sector is Bin Xin Textile Factory, which has been at the forefront of innovation and quality manufacturing in China. In this article, we will explore the key aspects of Bin Xin Textile Factory's operations, highlighting its achievements and challenges faced in the competitive market.

Production Process: Bin Xin Textile Factory employs a multi-stage production process that ensures high-quality end products. The factory starts with raw materials procurement, selecting only the finest cotton, silk, and other fibers for their use. These materials undergo rigorous cleaning and sorting processes to ensure consistency and uniformity. Next, the raw materials are processed through various stages of dyeing, spinning, weaving, and finishing. Each stage is meticulously monitored to maintain consistent standards across all products.

Quality Control: Quality control is a critical aspect of Bin Xin Textile Factory's operations. The factory has implemented advanced quality control systems that involve regular inspections and testing of every product before it leaves the factory. This includes using cutting-edge technology like machine vision systems to ensure accurate measurements and color consistency. Additionally, the factory has partnered with international quality certification bodies to uphold its reputation for excellence in the industry.

Market Positioning: Bin Xin Textile Factory has successfully positioned itself as a leading manufacturer in the Chinese textile industry. The company's focus on quality and innovation has earned it a strong reputation among consumers and suppliers alike. The factory's commitment to sustainability and environmental responsibility has also contributed to its market positioning. For example, Bin Xin has invested in renewable energy sources and implemented waste reduction strategies to reduce its carbon footprint.

Case Study: One notable case study involves a recent project where Bin Xin Textile Factory collaborated with a leading fashion brand to produce a line of eco-friendly clothing. The collaboration was driven by the need for sustainable materials and ethical production practices. The factory's commitment to these values aligned perfectly with the brand's mission, resulting in a successful partnership that not only boosted Bin Xin's sales but also raised awareness about responsible production practices within the industry.

Competitive Analysis: In today's highly competitive textile market, Bin Xin Textile Factory faces several challenges. On one hand, the industry is facing pressure from imported goods due to lower labor costs and increased efficiency. On the other hand, the rise of e-commerce platforms has disrupted traditional retail models, making it challenging for small and medium-sized enterprises like Bin Xin to compete effectively. To address these challenges, the factory is investing in digital marketing and developing new product lines that cater to niche markets.

Conclusion: Bin Xin Textile Factory is a testament to the resilience and adaptability of the textile industry. With its focus on quality, innovation, and sustainability, the factory has carved out a unique position in the market. As the industry continues to evolve, Bin Xin will need to stay ahead of the curve by embracing new technologies and staying true to its core values. By doing so, it can continue to be a leader in the global textile industry.

背景介绍

滨鑫纺织厂作为一家专注于纺织行业的现代化企业,以其先进的生产设备、环保理念和可持续发展战略,在国内外享有盛誉,本文将围绕滨鑫纺织厂展开,介绍其生产流程、环保措施、技术创新以及未来展望。

生产流程介绍

-

原料采购 滨鑫纺织厂主要采用环保型原料进行生产,包括棉花、涤纶等,在原料采购环节,企业严格把关,确保原料质量符合国家标准。

-

生产线介绍 滨鑫纺织厂拥有先进的生产线,包括织布、染整、印花等多个环节,在生产过程中,企业注重节能减排,采用自动化、智能化设备,提高生产效率,企业还注重环保治理,采用环保型染料和化学剂,减少对环境的污染。

环保措施

-

污水处理 滨鑫纺织厂设有专业的污水处理系统,对生产过程中产生的废水进行深度处理,达到国家排放标准后再排放,企业还积极推广循环利用,减少废水排放量。

-

节能减排 滨鑫纺织厂注重节能减排,采用高效节能设备,降低能源消耗,企业还加强员工培训,提高员工节能减排意识,企业还积极推广绿色生产模式,减少废弃物产生。

技术创新

-

新材料研发 滨鑫纺织厂不断进行新材料研发,采用环保型纤维材料,提高产品质量和性能,企业还注重研发绿色印染技术,降低环境污染。

-

智能化生产 滨鑫纺织厂采用智能化生产设备,提高生产效率和质量,企业还注重智能化管理,实现生产过程的自动化和智能化控制。

案例说明

以滨鑫纺织厂为例,介绍其在环保和可持续发展方面的具体实践。

-

环保实践案例 滨鑫纺织厂在原料采购环节严格把关,确保原料质量符合国家标准,企业注重环保治理,采用环保型染料和化学剂,减少对环境的污染,企业还积极推广循环利用,减少废水排放量,在生产过程中,企业注重节能减排,采用自动化、智能化设备,提高生产效率和质量,企业还加强员工培训,提高员工节能减排意识。

-

可持续发展实践案例 滨鑫纺织厂在绿色制造方面取得了显著成果,该企业在产品研发方面注重绿色环保设计,开发出符合市场需求的产品,该企业在供应链管理方面加强了与环保企业的合作,实现资源的循环利用和低碳生产,该企业还积极参与社会公益事业,为社会做出贡献。

展望滨鑫纺织厂的未来发展,该企业将继续秉承绿色制造和可持续发展的理念,不断提高生产效率和质量,加强技术创新和人才培养,该企业还将积极拓展国内外市场,提高品牌知名度和影响力,该企业还将加强与政府和社会各界的合作,共同推动纺织行业的绿色发展和可持续发展。

Articles related to the knowledge points of this article:

The Life and Business of Qian County Textile Factory Owner

The Dynamics and Innovations at Dunzhou Spray Water Textile Factory

The Textile Factory Uses a Humidifier to Maintain a Comfortable Work Environment