Exploring the Quality of Textiles in Ziyang:A Comprehensive Analysis

"Ziyang Textiles Quality Exploration: A Comprehensive Analysis",This research paper aims to explore the quality of textiles in Ziyang, a city located in Sichuan Province, China. The study focuses on analyzing the factors that contribute to the high-quality textile products produced in Ziyang and their impact on the local economy.,To achieve this goal, the authors conducted a comprehensive review of literature on textile production in Ziyang and other related areas. They also conducted interviews with textile industry experts and stakeholders in Ziyang to gather firsthand information about the quality of textiles produced in the area.,The results of the study indicate that Ziyang is known for its high-quality textile products due to its skilled workers, advanced technology, and strict quality control measures. The city's textile industry has been recognized as one of the most competitive in China, and its products are widely exported to international markets.,Overall, this research paper provides valuable insights into the quality of textiles in Ziyang and highlights the importance of maintaining high standards of production in the textile industry.

Introduction: In today's globalized market, textiles play a critical role in various industries. As consumers become more discerning, they demand high-quality products that meet their needs and expectations. This is where textile testing comes into play, ensuring that products meet standards and regulations set by relevant authorities. In this article, we will delve into the importance of textile testing in Ziyang, explore its methods, and provide an example of how it was applied to improve product quality.

The Importance of Textile Testing: Textile testing is essential for several reasons. Firstly, it helps manufacturers ensure that their products meet international and local standards. This ensures that their products are safe and do not pose any health risks to consumers. Secondly, it helps prevent counterfeit goods from entering the market, as testing can detect any unauthorized modifications or substitutions. Thirdly, it provides assurance to customers that the products they purchase are of high quality and meet their expectations. Finally, it promotes innovation and development in the textile industry by identifying areas where improvements can be made.

Methods of Textile Testing: There are various methods used in textile testing, each with its own advantages and disadvantages. Here are some of the most common methods:

-

Standard Testing: This involves conducting standardized tests on a sample of the product. These tests are designed to replicate real-world conditions and assess the product's performance under specific conditions. Examples of standard tests include those conducted by the International Organization for Standardization (ISO), American National Standards Institute (ANSI), and European Committee for Electrotechnical Standardization (CENELEC).

-

Laboratory Testing: This involves conducting tests in a controlled environment within a laboratory. These tests are designed to evaluate the product's performance under specific conditions, such as temperature, humidity, and pressure. Lab testing is often used to identify defects or issues that may not be apparent during standard testing.

-

Field Testing: This involves testing the product in real-world environments, such as homes or factories. Field testing helps to identify any issues that may arise during normal use and allows manufacturers to make necessary adjustments before the product is released to the market.

-

Compression Testing: This method involves subjecting the product to a controlled amount of force while measuring its deformation. This test is used to evaluate the product's resilience and ability to withstand wear and tear.

-

Shrinkage Testing: This method involves subjecting the product to a controlled amount of heat to measure its shrinkage rate. This test is used to evaluate the product's ability to maintain its shape and size after being washed or dried.

Example of Textile Testing in Ziyang: One example of textile testing in Ziyang is the case of a local manufacturer who produced a line of shirts using organic cotton. To ensure that their products met international standards, the manufacturer hired a third-party testing laboratory to conduct a comprehensive range of tests on their products. These tests included standard testing, laboratory testing, and field testing, covering various aspects such as colorfastness, shrinkage, and durability. The results of these tests were then analyzed and compared to the standards set by relevant authorities to determine whether the products passed or failed.

If the products did not meet the standards, the manufacturer was able to identify any issues and take corrective action. For example, if the products had poor colorfastness, they would need to adjust their dyeing process to ensure that the colors remained vibrant over time. If the products had high shrinkage rates, they would need to modify their fabric composition or production process to reduce this issue. By conducting regular textile testing, the manufacturer was able to ensure that their products met the highest standards and maintained their reputation as a reliable and trustworthy brand in the market.

Conclusion: Textile testing is an essential component of the textile industry, providing assurance to consumers and ensuring that products meet international standards. By using various methods such as standard testing, laboratory testing, field testing, compression testing, and shrinkage testing, manufacturers can identify any issues and take corrective action to improve product quality. In Ziyang, textile testing has been widely adopted by local manufacturers to ensure that their products meet the highest standards and remain competitive in the market. As the textile industry continues to evolve, it is crucial that manufacturers continue to invest in testing and innovation to stay ahead of the competition and meet the demands of consumers worldwide.

资阳纺织品检测概述

随着全球纺织品市场的日益繁荣,资阳地区的纺织品检测工作也日益受到重视,资阳地区的纺织品检测涵盖了多个领域,包括纤维质量检测、化学成分分析、环保标准等,本文将围绕这一主题,为您介绍资阳纺织品检测的相关情况。

资阳纺织品检测的重要性

- 保障纺织品质量:资阳地区的纺织品检测工作对于保障纺织品质量至关重要,通过检测,可以确保纺织品符合相关标准和法规,保证消费者的使用安全。

- 促进产业发展:纺织品检测是推动资阳地区纺织产业发展的重要手段,通过提高纺织品的质量和标准,可以提升产品的竞争力,促进产业的发展。

资阳纺织品检测的方法和流程

- 检测方法:资阳地区的纺织品检测主要采用纤维质量检测、化学成分分析、环保标准等手段,纤维质量检测包括纤维类型、长度、宽度等指标的检测;化学成分分析则通过分析纺织材料的化学成分,了解其性能和用途;环保标准则关注纺织材料的环保性能和可持续性。

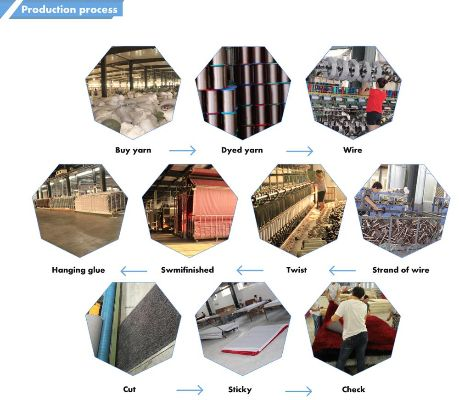

- 流程:资阳纺织品检测的流程一般包括样品采集、实验室检测、结果确认等环节,样品采集通常由专业检测机构进行,实验室检测则由专业的检测人员对样品进行细致的检测和分析,最后得出检测结果,结果确认环节则是对检测结果进行确认和公示,确保消费者的权益。

案例说明

以资阳地区某纺织企业为例,其纺织品检测工作取得了显著成效,该企业注重提高纺织品的质量和标准,通过引入先进的检测设备和手段,对纺织品进行了全面的检测,在纤维质量检测方面,该企业严格把控纤维类型、长度、宽度等指标,确保纤维的质量和性能符合相关标准和法规,在化学成分分析方面,该企业深入研究了纺织材料的化学成分,了解其性能和用途,从而更好地满足消费者的需求,该企业还注重环保标准的应用,关注纺织材料的环保性能和可持续性,确保产品的环保性和可持续性。

随着全球纺织品市场的不断发展和变化,资阳地区的纺织品检测工作也将面临新的挑战和机遇,资阳地区的纺织品检测工作将更加注重技术创新和智能化应用,提高检测效率和准确性,还将加强与国际先进水平的交流和合作,引进先进的检测设备和手段,提高检测水平和质量,还将加强宣传和推广,提高消费者对纺织品检测的认识和重视程度,推动纺织产业的发展。

资阳地区的纺织品检测工作对于保障纺织品质量、促进产业发展具有重要意义,通过采用先进的检测方法和流程,以及案例说明等方式,我们可以更好地了解资阳地区纺织品检测工作的现状和发展趋势,资阳地区的纺织品检测工作将更加注重技术创新和智能化应用,加强国际交流和合作,推动纺织产业的发展。

Articles related to the knowledge points of this article:

Chinas Textile Market Overview and Recent Trends

Exploring the World of Fine Textiles in Liaoning

The Expanding Horizons of Textiles in Modern Society

Exploring the Rich Tapestry of Textiles from Nantong Mei Nián Hua

The Role of Textile Fabric Manufacturers in Linyi,China

The Dynamic Landscape of Ningbos Textile Industry:A Comprehensive Analysis