The Hidden Dangers of Textile Mills:A Guide to Safety and Prevention

: Hidden Dangers of Textile Mills: A Guide to Safety and Prevention,Textile mills, often overlooked in the pursuit of efficiency and profitability, pose significant safety concerns that warrant attention. This guide aims to provide insights into the hidden dangers within these industrial settings, offering practical tips for enhancing workplace safety.,The hazards attributable to textile mills include exposure to toxic chemicals, noise pollution, and physical hazards such as machinery failure and falls. To mitigate these risks, a comprehensive approach is necessary, incorporating regular health checks, strict adherence to safety protocols, and the use of personal protective equipment (PPE) where required.,Furthermore, it is crucial to educate employees about potential hazards and their corrective actions, fostering a culture of safety awareness within the industry. Regular inspections and maintenance of machinery are also essential for preventing accidents and ensuring operational efficiency.,In conclusion, while textile mills may appear to be a safe haven for laborers, hidden dangers lurk beneath the surface. By implementing preventative measures and promoting a culture of safety, we can safeguard workers and promote a safer work environment.

Introduction: In the bustling world of textile manufacturing, safety is often overlooked. However, it is crucial for workers in these factories to understand the potential risks they face and take steps to ensure their well-being. This guide aims to provide an overview of the hazards commonly found in textile mills, including chemical exposure, physical injuries, and electromagnetic radiation. It will also highlight some preventive measures that can help minimize these risks and promote a safer working environment.

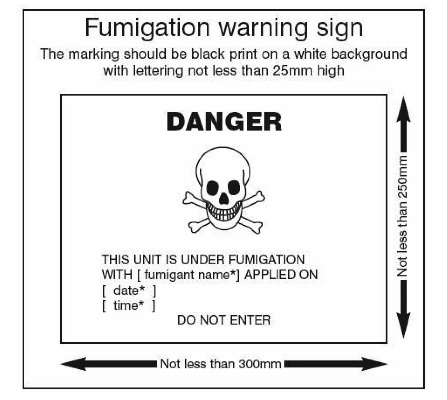

Chemical Exposure: Textile mills use a variety of chemicals to process fabrics, dyes, and other materials. These chemicals can be harmful if not handled properly, leading to respiratory problems, skin irritation, or even cancer. Some common chemicals used in textile mills include formaldehyde, acetone, and ammonia. Workers should always wear protective gear such as gloves, goggles, and a mask when handling these substances. Additionally, employers must ensure that proper ventilation systems are in place to limit the concentration of these chemicals in the air.

Physical Injuries: Textile mills can be dangerous places due to the heavy machinery involved in the production process. Workers may encounter accidents such as falls from heights, collisions with machinery, or burns from hot chemicals. To prevent these injuries, employers should implement strict safety protocols, including regular training for employees on how to operate machinery safely. Additionally, workers should follow proper workwear, including sturdy shoes and clothing that offer protection from sharp objects.

Electromagnetic Radiation: Electronic devices used in textile mills can generate electromagnetic radiation, which can pose a risk to workers' health. This radiation can cause headaches, fatigue, and even neurological disorders in some cases. To minimize this risk, employers should ensure that electronic equipment is kept away from workers' bodies and avoid using them during peak hours when workers are most vulnerable. Additionally, workers should take breaks regularly to allow their body to recover from the effects of electromagnetic radiation.

Prevention and Measures: To protect workers from the dangers of textile mills, employers must implement a comprehensive safety program. This program should include regular safety training for all employees, including emergency procedures, first aid, and fall prevention techniques. Employers should also provide access to personal protective equipment (PPE) such as gloves, goggles, and masks, as well as ensuring that proper ventilation systems are in place. Additionally, employers should monitor workplace conditions closely to identify any potential hazards and take corrective action immediately.

Case Study: One example of a textile mill where safety was compromised occurred in the United States in 2014. A worker at a large textile company in New Jersey fell from a high platform while attempting to repair a machine. The worker sustained severe injuries that required multiple surgeries and months of rehabilitation. Had the company implemented proper safety measures, this tragedy could have been prevented.

Conclusion: In conclusion, textile mills present unique challenges for workers who must navigate complex machinery and potentially hazardous chemicals. By understanding the risks associated with each type of hazard and implementing effective prevention and control measures, employers can create a safer work environment for their employees. Remember, safety is not just about preventing accidents; it is also about promoting long-term health and well-being for those who work in these industries.

背景介绍

网络上流传了一段关于纺织厂危险视频,引发了公众对纺织行业安全问题的广泛关注,视频中展示了工厂生产过程中的潜在危险,包括高温、高压、有毒化学品等,令人触目惊心,为了更好地了解这一事件,我们进行了一篇英文口语化内容的撰写。 分析 主要包括以下几个方面:

- 高温工作环境:纺织厂内的生产车间充斥着高温环境,工人们长时间在高温下工作,存在极大的安全隐患。

- 高压设备操作:视频中展示了工厂使用高压设备进行生产操作,但操作不当可能导致设备故障或人员伤亡。

- 化学物质泄漏:视频中还展示了工厂可能存在化学物质泄漏的情况,对环境和工人健康构成潜在威胁。

英文案例说明

为了更好地说明这一事件,我们可以引用一个英文案例,假设某纺织厂在生产过程中发生了类似危险的操作,具体如下:

某纺织厂在高温环境下进行生产操作,由于缺乏必要的防护措施和操作规程,导致工人在高温下长时间工作,引发了严重的安全事故,工人们被紧急送往医院进行治疗,造成了人员伤亡和财产损失。

英文口语化内容写作

以下是一个英文口语化内容的写作示例: 纺织厂危险视频引发的安全警示

大家好,最近网络上流传了一段关于纺织厂危险视频,引发了公众对纺织行业安全问题的广泛关注,这段视频让我们看到了纺织厂生产过程中的潜在危险,让我们不禁为工人们的生命安全捏了一把汗。

让我们看看视频中的关键信息,视频显示纺织厂的生产车间充斥着高温环境,工人们长时间在高温下工作,视频还展示了工厂使用高压设备进行生产操作的情况,这些操作虽然提高了生产效率,但也增加了潜在的危险性,如果操作不当或设备故障,都可能导致严重的安全事故。

为了更好地了解这一事件,我们可以引用一个英文案例来说明,假设某纺织厂在生产过程中发生了类似危险的操作,导致了严重的安全事故,在这种情况下,工厂应该立即采取措施加强安全管理,提高员工的安全意识,确保生产过程中的安全操作,政府和监管部门也应该加强对纺织行业的监管,确保其生产过程符合安全标准。

我们还需要强调的是,纺织行业是一个高危行业,任何时候都应该高度重视安全问题,企业应该加强安全生产管理,制定和完善安全操作规程,确保员工的安全,政府和社会也应该加强对纺织行业的宣传和教育,提高公众的安全意识。

我们呼吁大家关注纺织厂危险视频,提高对纺织行业安全问题的关注度,我们也应该加强对纺织行业的监管和管理,确保其生产过程符合安全标准,我们才能保障工人们的生命安全,维护社会的稳定和和谐。

Articles related to the knowledge points of this article: