The Repurposing of Waste in the Textile Industry

"Repurposing of Waste in the Textile Industry",In recent years, the textile industry has faced challenges due to increased demand for sustainable and eco-friendly materials. To address this issue, waste from the production process can be repurposed into new products. This paper discusses the potential of repurposing waste in the textile industry and its impact on reducing environmental pollution and promoting economic growth.,The textile industry generates a significant amount of waste, including textile scraps, dye sludge, and other discarded materials. These wastes can be repurposed into new products such as carpet fibers, clothing, and even building materials. By repurposing these wastes, the textile industry not only reduces its environmental footprint but also creates new markets for recycled materials.,There are several ways to repurpose waste in the textile industry. For example, textile scraps can be used to produce new yarns or woven fabrics. Dye sludge can be converted into pigments that can be used in paints, coatings, and other products. Additionally, wastewater treatment plants can use textile waste as a source of energy or fertilizer.,Repurposing waste in the textile industry is not only environmentally friendly but also economically beneficial. It creates new jobs in the recycling and reprocessing sector, while also reducing the cost of raw materials for the textile industry. Moreover, it encourages innovation and creativity among designers and manufacturers, leading to new product development and market expansion.,In conclusion, repurposing waste in the textile industry is an effective way to reduce environmental pollution and promote economic growth. By utilizing the resources generated from textile waste, we can create new markets for recycled materials and contribute to a more sustainable future for our planet.

Introduction: As one of the world's largest industries, the textile industry generates a significant amount of waste. However, this waste can be transformed into valuable resources if it is managed properly. In this article, we will explore how textile factories are turning their waste into new products and services. We will also discuss some successful cases that demonstrate the potential of waste repurposing in the textile industry.

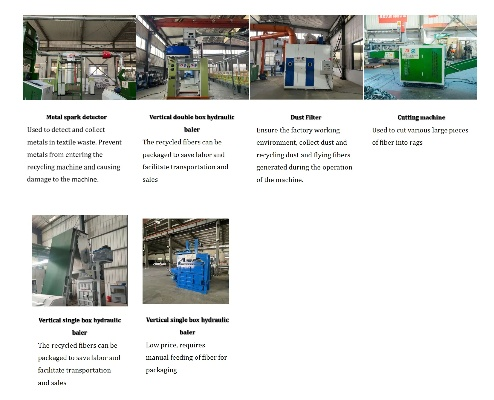

Waste Management in the Textile Industry: The textile industry produces a large amount of waste, including scrap fabric, dye residues, and chemical byproducts. These waste streams can be challenging to manage due to their complexity and diversity. However, with proper planning and technology, these waste streams can be turned into new products and services.

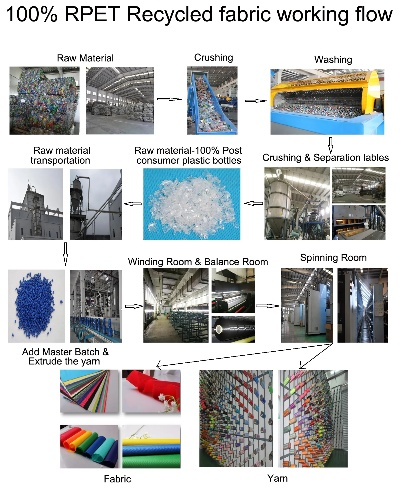

One way to manage textile waste is through recycling. Many textile factories have implemented recycling programs that involve sorting and processing their waste streams to create new products such as carpet fibers, upholstery fabrics, and even biodegradable materials. For example, a textile company in China has developed a process that uses recycled polyester fabric to produce eco-friendly carpets that are sold at a premium price.

Another way to repurpose textile waste is through composting. Composting involves the decomposition of organic matter, which can be used to produce fertilizers or soil amendments. This process is particularly useful for textile companies that produce clothing or other textile products that contain natural fibers such as cotton or wool. By using the composted material as fertilizer, textile factories can reduce their environmental impact while still producing high-quality products.

Repurposing Waste into New Products: There are many ways to repurpose textile waste into new products. One method is to use the waste to make upholstery or carpet fibers. For example, a textile company in the United States has developed a process that uses recycled polyester fabric to produce upholstery fabrics that are sold at a premium price. Another example is a company in India that uses waste fabric from old clothes to create soft toys and blankets.

Another approach is to use the waste as a source of energy. For example, textile companies can use their waste materials to produce biogas, which can be used for cooking or heating. Biogas can also be used to power electric generators, which can then be used to provide electricity to nearby homes or businesses.

Successful Case Studies: There are many successful case studies that demonstrate the potential of waste repurposing in the textile industry. One such case is a company in Italy that repurposed its waste fabric into eco-friendly carpets that are sold at a premium price. Another case is a company in China that developed a process that uses recycled polyester fabric to produce upholstery fabrics that are sold at a premium price.

Conclusion: In conclusion, the textile industry can turn its waste into valuable resources through proper management and technology. By recycling, composting, and repurposing waste into new products, textile factories can reduce their environmental impact while still producing high-quality products. There are many successful case studies that demonstrate the potential of waste repurposing in the textile industry. As more companies adopt sustainable practices, we can expect to see even greater progress in this area in the future.

大家好,今天我们要探讨一个纺织厂的废品问题,纺织厂在生产过程中会产生大量的废品,这些废品不仅对环境造成影响,也可能对资源造成浪费,让我们一起来了解这个话题。

废品种类及来源

废品主要包括各种废布、废纱线、废塑料等,这些废品主要来源于生产过程中的各种环节,例如裁剪、缝纫、染色等,还有一些不可预测的因素也会产生废品,例如设备故障、原料供应不足等。

废品处理现状

纺织厂的废品处理方式主要依赖于简单的回收和简单的处理,虽然在一定程度上可以减少对环境的污染,但仍然存在一些问题,废品的分类和处理不够规范,缺乏有效的资源回收和再利用机制,一些废品可能被随意丢弃或随意处理,这给环境和社会带来了一定的影响。

案例分析

为了更好地了解废品处理现状,我们可以引入一个具体的案例,假设有一个纺织厂,其废品处理存在以下问题:

- 废品来源不明确:该纺织厂的部分废品可能来自于不可预测的因素,导致废品种类繁多,处理难度增加。

- 缺乏有效的资源回收和再利用机制:该纺织厂在废品处理过程中,缺乏有效的资源回收和再利用机制,导致部分废品被随意丢弃或随意处理。

解决方案与建议

针对上述问题,我们可以提出以下解决方案和建议:

- 加强监管和规范管理:政府和企业应加强对纺织厂废品处理的监管和规范管理,制定更加严格的废品处理标准和规范,建立更加完善的资源回收和再利用机制,提高废品处理的效率和效益。

- 采用先进的处理技术:纺织厂可以引进先进的处理技术,提高废品处理的效率和效果,采用分类回收、再生利用等技术手段,减少废品的产生和减少对环境的污染。

- 加强宣传和教育:政府和企业应加强宣传和教育,提高公众对环境保护的认识和意识,鼓励和支持企业采用环保生产方式,减少对资源的浪费和对环境的污染。

纺织厂的废品问题是一个复杂而严峻的问题,需要政府、企业和社会各方面的共同努力来解决,只有通过加强监管和规范管理、采用先进的处理技术、加强宣传和教育等措施,才能有效地解决纺织厂的废品问题,保护环境和社会可持续发展,我们也应该鼓励和支持企业采用环保生产方式,推动绿色发展。

Articles related to the knowledge points of this article: