The Essential Guide to Textile Whiteness Ph Value Requirements

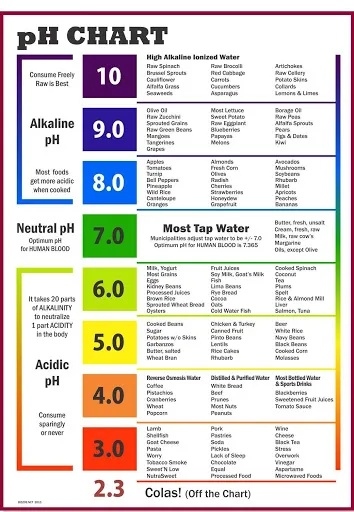

This essential guide provides comprehensive information on the requirements for textile whiteness in terms of Ph Value. It covers various aspects such as the definition and meaning of Ph Value, its importance in determining the quality of textile products, and how it is measured and interpreted. The guide also discusses the factors that affect the Ph Value of textiles, including the type of fiber, dyeing process, and environmental conditions. Additionally, it offers practical tips and advice on how to achieve optimal whiteness levels in textile production. Overall, this guide is an essential resource for anyone involved in the textile industry, providing a clear and concise overview of the key concepts and techniques related to textile whiteness in terms of Ph Value.

Introduction: The textile industry is a complex and diverse sector that demands precision in the color and quality of its products. One critical aspect of this industry is ensuring that textiles meet specific standards regarding whiteness, which is often measured using the "Ph value." In this guide, we will delve into the concept of Ph values, their importance in textiles, and how they are measured. We will also provide an overview of common Ph values for different types of textiles and offer some practical examples to illustrate the application of these standards.

Textile Whiteness Ph Value Concept:

Ph values are used to describe the relative brightness or darkness of a textile's color. They are typically expressed as a percentage scale, with 100% indicating a completely white color and 0% indicating a completely black color. The term "Ph" comes from the Greek word "phenomenon," which means "appearance."

In the textile industry, Ph values are crucial for several reasons. Firstly, they ensure that textiles meet consumer expectations and preferences. For example, if a textile is advertised as being "whiter than white," it should actually have a Ph value closer to 95-98%, not just 75-80%. Secondly, Ph values are used to determine whether a textile meets certain regulatory requirements. For instance, many countries have set minimum Ph values for certain types of textiles, such as baby clothes or medical supplies.

Common Ph Values for Different Textiles:

Here is an overview of some common Ph values for different types of textiles:

| Type of Textile | Ph Value |

|---|---|

| Cotton | 85-92% |

| Linen | 86-94% |

| Silk | 93-98% |

| Wool | 95-98% |

| Polyester | 85-92% |

| Nylon | 85-92% |

| Rayon | 90-95% |

| Taffeta | 85-90% |

| Blended fabrics | 85-92% |

Example:

To illustrate the application of these Ph values, let's consider a hypothetical scenario where a textile company wants to produce baby clothes with a Ph value of 95%. This would mean that the fabric should be at least 95% white in color, meeting the consumer's expectations and ensuring compliance with regulatory requirements.

Practical Application:

In practice, measuring Ph values can be done using various methods, including spectrophotometry, colorimeters, and visual inspection. Spectrophotometry involves shining light through a sample and measuring the intensity of the reflected light. Colorimeters use a sensor to measure the color temperature of the fabric. Visual inspection involves comparing the fabric to a known standard and determining its relative brightness.

Conclusion:

Understanding and adhering to Ph values is essential for the success of any textile product. Companies must ensure that their products meet consumer expectations and regulatory requirements by accurately measuring and reporting Ph values. With the right knowledge and tools, businesses can produce high-quality textiles that meet the needs of their customers and comply with industry standards.

背景介绍

纺织品作为日常生活中不可或缺的衣着材料,其品质直接关系到人们的穿着舒适度和健康,白色纺织品因其纯净、无瑕的特性,在市场上备受青睐,为了确保纺织品的质量和安全性,白色纺织品的PH值要求变得尤为重要。

白色PH值要求概述

白色纺织品的PH值要求主要涉及纺织纤维的酸碱度指标,根据相关标准,纺织品中的PH值应保持在一定的范围内,以确保其符合健康、环保和安全的要求。

PH值的范围通常在7.0至9.5之间,具体数值取决于纺织纤维的类型和用途,对于白色纺织品来说,其PH值要求更为严格,以确保其在洗涤、染色等过程中不易变色、褪色,同时保持其应有的光泽和质地。

案例分析

以下是一个纺织品白色PH值要求的案例分析:

某品牌白色纺织品PH值要求

该品牌在生产白色纺织品时,对其PH值有着严格的要求,他们注重产品的环保性和安全性,因此在选择纺织纤维时,会严格筛选符合PH值要求的纤维,他们还会对生产过程中的各个环节进行严格控制,以确保最终产品的品质和安全性。

该品牌在选择纺织纤维时,会关注纤维的酸碱度指标是否符合标准,他们会通过检测纤维的化学成分、物理性能等指标,来确定其是否符合PH值要求,该品牌还会对生产过程中的各个环节进行严格控制,包括纺丝、织造、染整等环节,以确保最终产品的品质和稳定性。

白色纺织品PH值对洗涤效果的影响

在洗涤过程中,白色纺织品的PH值变化是一个重要的问题,如果纺织品在洗涤过程中PH值过高或过低,都可能对其品质和安全性造成影响,对于白色纺织品来说,其PH值的稳定性和洗涤效果尤为重要。

一些高品质的白色纺织品在洗涤过程中不易变色、褪色,保持其应有的光泽和质地,这是因为这些纺织品采用了符合PH值要求的纤维,并且在生产过程中严格控制各个环节,一些低质量的白色纺织品在洗涤过程中可能会出现变色、褪色等问题,对于纺织品生产企业来说,确保纺织品符合PH值要求是非常重要的。

补充说明(表格)

以下是关于纺织品白色PH值要求的补充说明表格:

| 指标 | 要求范围 | 具体标准 |

|---|---|---|

| 纺织纤维的酸碱度指标 | 0至9.5 | 根据相关标准进行检测和评估 |

| 生产过程控制 | 选择符合PH值要求的纤维 | 通过检测纤维的化学成分、物理性能等指标进行评估 |

| 生产环节控制 | 纺丝、织造、染整等环节 | 严格控制各个环节,确保产品质量和稳定性 |

| 洗涤效果 | 不易变色、褪色,保持光泽和质地 | 根据实际测试结果进行评估 |

| 安全性和环保性 | 符合相关标准和法规要求 | 确保产品符合健康、环保和安全的要求 |

纺织品白色PH值要求是确保纺织品品质和安全性的重要指标之一,生产企业应该注重纺织纤维的筛选和控制环节,以确保最终产品的品质和稳定性,对于消费者来说,选择符合PH值要求的纺织品也是非常重要的,在实际使用中,消费者可以根据自己的需求和实际情况选择合适的纺织品。

Articles related to the knowledge points of this article:

Ranking the Number of Chinese Textile Brands

Exploring the Rich Traditions of Nantong Yayu Fang Textiles