Textile Hardening and Stabilization Techniques:A Comprehensive Guide

"Textile Hardening and Stabilization Techniques: A Comprehensive Guide" is a comprehensive guide to textile hardening and stabilization techniques. It covers various methods, including chemical treatment, physical treatment, and biological treatment, which can be used to improve the strength, durability, and resistance of textile materials. The guide provides detailed information on the selection of appropriate techniques based on the specific needs of the textile material and its intended application. It also covers the effects of various factors on the effectiveness of these techniques, such as temperature, pH, and contact time. Overall, this guide provides a valuable resource for those working with textile materials and seeking to improve their properties through hardening and stabilization techniques.

Introduction: The textile industry is a multi-billion dollar sector, responsible for producing a wide range of fabrics, from casual wear to high-end fashion. One crucial aspect of the textile industry is the ability to harden and stabilize these fabrics to enhance their durability and performance. In this guide, we will explore various techniques that can be used to achieve this goal through the application of textile hardening and stabilization agents.

Textile Hardening and Stabilization Agents: There are several types of textile hardening and stabilization agents available in the market, each with its unique properties and applications. Some of the commonly used agents include:

-

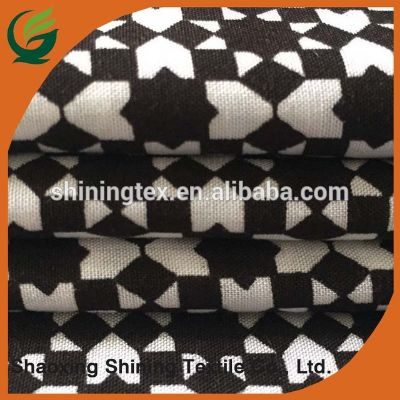

Acrylic Resins: These are synthetic resins that can be applied topically or as a coating on the fabric. They provide excellent bonding and adhesion between the fibers, making the fabric more resistant to wear and tear.

-

Silk Suiting: This agent is derived from silk and is used to create a softer, more luxurious finish on fabrics. It provides excellent flexibility and breathability, making it ideal for use in sportswear and swimwear.

-

Polyurethane: This agent is widely used in the automotive industry but can also be applied to fabrics to provide a smooth, glossy finish. It is highly resistant to water and chemicals, making it ideal for outdoor wear.

-

PVC Plasticizers: These agents soften and plasticize the fabric by dissolving the fibers' natural oils, making them more flexible and stretchable. They are commonly used in apparel and footwear to improve comfort and fit.

-

Modacrylics: These are a type of polyester that has been modified to improve its performance characteristics. They provide excellent resistance to stains, wrinkles, and fading, making them ideal for use in high-traffic areas like gymnasiums and swimming pools.

Application Techniques: Once you have selected the right textile hardening and stabilization agent, there are several techniques that can be employed to apply it effectively:

-

Topical Application: This technique involves applying the agent directly to the fabric surface using a brush, spray bottle, or applicator disc. This method is suitable for small areas or individual pieces of fabric.

-

Coating Application: This technique involves applying the agent as a thin layer on the fabric surface using a brush, roller, or spray gun. This method is suitable for larger areas or multiple pieces of fabric.

-

Embossing: This technique involves creating a raised pattern on the fabric surface using a hot iron or steamer. This method is suitable for creating a unique texture or pattern on the fabric.

-

Embroidery: This technique involves adding intricate details to the fabric using thread and needle. This method is suitable for creating patterns or designs that cannot be achieved using other techniques.

Case Study: One example of successful textile hardening and stabilization is seen in the production of athletic wear. A company specialized in sportswear developed a new fabric that was designed to withstand intense physical activity. To achieve this, they applied a specialized acrylic resin to the fabric, which not only provided excellent durability but also enhanced the fabric's breathability and moisture management properties. The result was a fabric that was both lightweight and strong, making it ideal for sports such as running and cycling.

Conclusion: Textile hardening and stabilization techniques play a crucial role in enhancing the performance and longevity of textile products. By selecting the right agent and applying it correctly, manufacturers can create fabrics that are not only visually appealing but also functional and durable. As technology continues to advance, we can expect to see even more innovative and effective methods of textile hardening and stabilization in the future.

随着纺织行业的快速发展,对纺织品加硬定型的需求日益增长,纺织品加硬定型胶作为一种重要的材料,在提高纺织品强度、耐磨性等方面发挥着重要作用,本文将围绕纺织品加硬定型胶的主题,从多个角度进行深入探讨。

纺织品加硬定型胶的基本概念与特性

纺织品加硬定型胶是一种高分子材料,主要用于增强纺织品的硬度和定型效果,其主要特性包括高强度、耐磨性、耐腐蚀性等,该产品具有优良的粘接性能,能够与多种材料进行牢固的粘接。

纺织品加硬定型胶的应用场景与案例分析

应用场景

纺织品加硬定型胶广泛应用于各种纺织品的加工和制作过程中,在服装、家居用品、工业制品等领域,纺织品加硬定型胶被广泛应用于提高纺织品的强度和耐磨性,该产品还可以用于制作各种鞋材、箱包材料等。

案例分析

以某知名纺织企业为例,该企业采用先进的纺织品加硬定型技术,成功提高了纺织品的强度和耐磨性,该企业在生产过程中,使用了一种新型的纺织品加硬定型胶,通过精确控制配方和工艺参数,使得纺织品具有更高的强度和耐磨性,该企业还注重产品的环保性能,采用环保材料制作产品,符合现代消费者的需求。

纺织品加硬定型胶的技术特点与优势

技术特点

纺织品加硬定型胶具有高强度、耐磨性、耐腐蚀性等优点,该产品还具有优良的粘接性能,能够与多种材料进行牢固的粘接,该产品还具有环保、节能等优点,符合现代消费者的需求。

优势分析

在性能方面,纺织品加硬定型胶具有以下优势:该产品能够提高纺织品的强度和耐磨性,延长产品的使用寿命;该产品能够适应不同的纺织材料和加工工艺,具有良好的通用性;该产品还具有环保、节能等优点,符合现代消费者的需求。

纺织品加硬定型胶的应用实例与市场前景

应用实例

在纺织行业中,纺织品加硬定型胶的应用实例非常广泛,在服装行业中,纺织品加硬定型胶被广泛应用于提高服装的强度和耐磨性,使得服装更加耐用、美观;在鞋材行业中,纺织品加硬定型胶被广泛应用于制作各种鞋材,提高了鞋材的质量和性能,该产品还广泛应用于其他领域,如箱包材料、帐篷材料等。

市场前景

随着人们对纺织品品质和性能的要求不断提高,纺织品加硬定型胶的市场前景非常广阔,随着技术的不断进步和产品的不断创新,纺织品加硬定型胶将会更加广泛地应用于各个领域,成为纺织行业的重要材料之一,随着环保意识的不断提高,纺织品加硬定型胶也将更加注重环保、节能等优点,符合现代消费者的需求。

纺织品加硬定型胶作为一种重要的材料,在提高纺织品强度、耐磨性等方面发挥着重要作用,该产品具有优良的粘接性能、高强度、耐磨性、耐腐蚀性等优点,同时还具有环保、节能等优点,在应用场景方面,该产品被广泛应用于各种纺织品的加工和制作过程中,在未来,随着技术的不断进步和产品的不断创新,纺织品加硬定型胶将会更加广泛地应用于各个领域。

Articles related to the knowledge points of this article:

Job Opportunities at Nantong Routul Textile Factory

Chinas Textile Trade Strength and Global Impact

The 2018 Shanghai Home Textiles Autumn Trends

Navigating the Global Market:The Price Landscape of Luo Lei Textiles