The Art of Adhesive Finishing in Textiles

The art of adhesive finishing in textiles is an intricate process that involves the use of specialized adhesives to bond fabrics together. This technique is crucial in creating durable, long-lasting garments and accessories. The key components of adhesive finishing include the selection of the right adhesive, proper application techniques, and the use of auxiliary materials such as backing, interlocking, and reinforcement. The adhesive must be selected based on the specific requirements of the project, including its intended use, durability, and resistance to wear and tear. Once the adhesive has been applied, it is essential to follow proper application techniques to ensure optimal results. This includes using a suitable adhesive roller or spray applicator, applying even pressure, and ensuring that the adhesive is completely absorbed into the fabric. In addition, auxiliary materials such as backing, interlocking, and reinforcement can be used to enhance the strength and durability of the finished product. Overall, the art of adhesive finishing in textiles requires careful attention to detail and expertise in the application of specialized materials to create high-quality products that withstand the test of time.

Introduction Adhesive finishing is an essential step in the production process of textiles, as it provides a strong bond between fabric layers and protects them from wear and tear. In this article, we will explore the various methods used to apply adhesives to textiles, their advantages and disadvantages, and how they are applied in different industries. We will also present an example of a successful adhesive application case study.

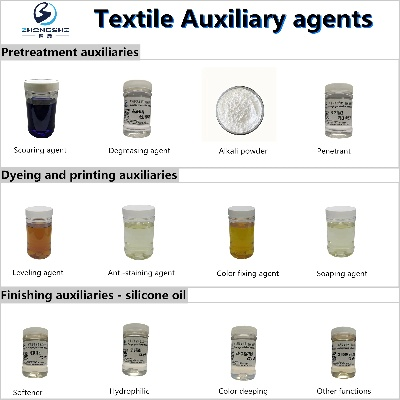

Adhesive Types: There are several types of adhesives used in textiles, including hot melt adhesives, solvent-based adhesives, water-based adhesives, and pressure-sensitive adhesives. Each type has its own unique properties and applications.

Hot Melt Adhesives: These adhesives are heated to a liquid state before being applied to the fabric. They have a high strength and durability but can be difficult to remove once applied.

Solvent-Based Adhesives: These adhesives contain solvents that dissolve the fabric fibers, creating a strong bond between the adhesive and the fabric. They are commonly used in industrial applications where flexibility is not critical.

Water-Based Adhesives: These adhesives are water-based and do not require heating. They are eco-friendly and easy to use but may not provide the same strength as other adhesives.

Pressure-Sensitive Adhesives: These adhesives release when subjected to pressure, providing a temporary bond between the adhesive and the fabric. They are commonly used for temporary applications such as garment repairs.

-

Application Methods: There are several ways to apply adhesives to textiles, including direct application, spray application, and brush application. Direct application involves applying the adhesive directly to the fabric using a knife or scissors. Spray application uses a spray gun to coat the fabric with adhesive, while brush application involves using a brush to spread the adhesive evenly over the fabric surface.

-

Advantages and Disadvantages: The choice of adhesive and application method depends on the specific requirements of the textile product. Some advantages of using adhesives include improved durability, reduced weight, and increased aesthetic appeal. However, there are also some disadvantages to consider, such as potential health hazards from certain solvent-based adhesives, and difficulty in removing adhesive residues after washing.

-

Industry Applications: Adhesives are used in a wide range of industries, including apparel, home furnishings, automotive, and electronics. In apparel industry, adhesives are used to attach labels, patches, and other decorative elements to clothing. In home furnishings, adhesives are used to attach curtains, upholstery, and other decorative items to furniture. In automotive industry, adhesives are used to attach seat covers, door panels, and other interior trim pieces to vehicles. In electronics industry, adhesives are used to attach circuit boards, connectors, and other electronic components to printed circuit boards.

-

Case Study: One example of a successful adhesive application case study is the development of a new waterproof adhesive for outdoor sportswear. A team of researchers at a leading textile company developed a novel adhesive that was tested on various fabrics and materials. The adhesive demonstrated excellent adhesion strength and durability in wet conditions, making it ideal for use in outdoor sportswear. The company successfully launched the new waterproof adhesive into the market, resulting in increased sales and customer satisfaction.

Conclusion Adhesive finishing is an important aspect of textile production, providing a strong bond between fabric layers and protecting them from wear and tear. There are various types of adhesives available, each with its own unique properties and applications. The choice of adhesive and application method depends on the specific requirements of the textile product. Successful adhesive applications have been achieved in various industries, including apparel, home furnishings, automotive, and electronics. By understanding the benefits and limitations of different adhesives and applying them correctly, textile manufacturers can create products that meet the needs of their customers.

在探讨纺织品如何粘胶的问题时,我们可以从多个角度来详细说明,以下是一篇关于纺织品粘胶的英文口语化内容,并附上英文案例说明。

在日常生活中,我们经常需要使用纺织品来制作各种物品,而粘胶技术则是确保纺织品贴合和固定的重要手段,纺织品是如何粘胶的呢?下面我们将通过几个方面来详细介绍。

纺织品粘胶的基本原理

- 粘合剂类型:常见的纺织品粘胶方法包括热熔胶、双面胶带、无纺布等。

- 粘合过程:粘胶通常是通过将粘合剂涂抹在需要粘合的纺织品表面,然后通过一定的压力和时间使其牢固地粘合在一起。

纺织品粘胶的具体操作步骤

- 选择合适的粘胶材料:根据需要粘合的纺织品材质和形状,选择合适的粘胶材料。

- 准备工作:清洁待粘合的纺织品表面,确保其干燥、平整。

- 涂抹粘胶:使用适量的粘胶涂抹在需要粘合的纺织品表面。

- 施加压力:使用适当的压力和时间,使粘胶与纺织品紧密贴合。

- 检查和固定:检查粘合效果,确保粘合牢固可靠。

案例说明

下面通过一个具体的案例来说明纺织品粘胶的过程:

某品牌服装面料粘合

某品牌服装面料生产商使用热熔胶进行粘合,他们选择合适的热熔胶并涂抹在需要粘合的服装面料表面,他们施加适当的压力和时间,使热熔胶与面料紧密贴合,经过烘干处理,成功完成了服装面料的粘合。

补充说明(表格)

以下是关于纺织品粘胶的一些补充说明信息,用表格形式展示:

| 类别 | 术语 | 说明 |

|---|---|---|

| 粘合剂类型 | 热熔胶、双面胶带、无纺布等 | 这些是常见的纺织品粘胶方法,可以根据具体需求选择合适的材料 |

| 操作步骤 | 选择合适的粘胶材料 → 准备工作 → 涂抹粘胶 → 施加压力 → 检查和固定 | 这些步骤是确保纺织品粘胶成功的关键步骤 |

| 工作环境 | 清洁干燥的工作环境 → 无尘无菌的工作环境 | 为了确保粘胶效果和纺织品质量,工作环境要求严格 |

| 应用场景 | 衣物、家居装饰品、包装材料等 | 纺织品粘胶广泛应用于各种领域,如服装、家居用品等 |

纺织品粘胶是一个相对简单的过程,但需要注意选择合适的材料和确保工作环境的要求,通过正确的操作步骤和注意事项,我们可以成功地将纺织品与其它材料牢固地粘合在一起,我们也应该注意选择合适的粘胶材料和工作环境的要求,以确保最终产品的质量和性能。

Articles related to the knowledge points of this article:

Trends in Technological Textiles and Clothing:A Comprehensive Guide

The 2016 National Textile Manufacturers:An Overview

Industrial Textiles Listed Companies:An Overview