Thermal Performance of Textile Materials:A Comprehensive Analysis

"Textile Materials' Thermal Performance: A Comprehensive Analysis",This paper provides a comprehensive analysis of the thermal performance of textile materials. It discusses the various factors that influence the thermal properties of textile materials, including their structure, composition, and processing methods. The study examines the impact of temperature, humidity, and airflow on the thermal conductivity, insulation, and moisture absorption of textile materials. Additionally, it explores the relationship between thermal performance and the wearability, comfort, and durability of textile products.,The paper highlights the importance of understanding the thermal properties of textile materials for designing effective thermal management systems in buildings, clothing, and other applications. It also emphasizes the need for developing advanced materials with tailored thermal properties to meet the ever-increasing demands for energy efficiency and sustainability. Overall, the study provides valuable insights into the complex interplay between thermal performance and other important properties of textile materials, and offers practical recommendations for improving their performance in various applications.

Textile materials are an integral part of our daily lives, from clothing and bedding to upholstery and furnishings. Their thermal performance is crucial for ensuring comfort, safety, and energy efficiency in various applications. In this article, we will explore the different aspects of textile material thermal properties, including their classification, testing methods, and practical applications. We will also present a case study to demonstrate how these properties can be used in real-world scenarios.

Classification of Textile Thermal Performance

Textile thermal properties refer to the ability of textile materials to resist heat transfer and maintain their structural integrity under thermal stress. There are several classifications of textile thermal properties, depending on the type of test they are evaluated for.

-

Static Thermal Properties: These properties are evaluated by measuring the rate at which a textile material loses or gains heat under static conditions. They include thermal conductivity (heat transfer rate), thermal diffusivity (rate of heat diffusion), and thermal resistance (ability to resist heat transfer).

-

Dynamic Thermal Properties: These properties are evaluated by measuring the rate at which a textile material loses or gains heat under dynamic conditions. They include thermal expansion coefficient (change in length with temperature) and thermal contraction coefficient (change in length with temperature).

-

Thermophysical Properties: These properties are evaluated by combining both static and dynamic thermal properties to determine the overall thermal behavior of a textile material. They include thermal conductivity, thermal diffusivity, thermal expansion coefficient, and thermal contraction coefficient.

Testing Methods for Textile Thermal Performance

There are several testing methods used to evaluate textile thermal properties, including:

-

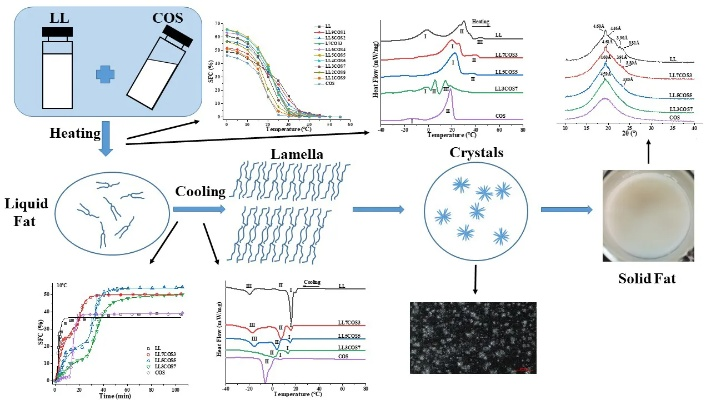

Differential Scanning Calorimetry (DSC): This method measures the amount of heat absorbed or released by a sample as it undergoes a step change in temperature. It is commonly used to evaluate the thermal conductivity and thermal diffusivity of textile materials.

-

Thermogravimetric Analysis (TGA): This method measures the weight loss of a sample as it undergoes a step change in temperature. It is commonly used to evaluate the thermal expansion coefficient and thermal contraction coefficient of textile materials.

-

Hot-press testing: This method involves applying heat to a sample while monitoring its weight loss and changes in dimensions over time. It is commonly used to evaluate the thermal conductivity and thermal diffusivity of textile materials.

Practical Applications of Textile Thermal Performance

Textile thermal properties play a significant role in various industries, including apparel, home furnishings, and construction materials. Here are some examples of how these properties can be applied:

-

Apparel: Textile materials with high thermal conductivity and low thermal diffusivity can prevent heat buildup during wear, resulting in improved comfort and reduced discomfort. For example, breathable fabrics made from polyester and spandex have high thermal conductivity and low thermal diffusivity, making them ideal for sportswear and activewear.

-

Home Furnishing: Textile materials with high thermal resistance can help reduce heat loss during use, resulting in improved energy efficiency. For example, upholstered furniture made from wool and silk have high thermal resistance, making them ideal for winter use.

-

Construction Materials: Textile materials with high thermal conductivity and low thermal diffusivity can improve the thermal performance of building materials, reducing the risk of fire and heat spread. For example, roofing materials made from asbestos fiberglass have high thermal conductivity and low thermal diffusivity, making them ideal for hot climates.

Case Study: Textile Thermal Performance in the Fashion Industry

In the fashion industry, textile materials with high thermal conductivity and low thermal diffusivity are essential for creating comfortable and stylish clothing. For example, swimwear made from polyester and spandex has high thermal conductivity and low thermal diffusivity, making it ideal for hot weather activities like swimming and surfing. Additionally, swimwear made from bamboo and linen has high thermal conductivity and low thermal diffusivity, making it ideal for cold weather activities like skiing and snowboarding.

Conclusion

Textile thermal properties play a crucial role in determining the comfort, safety, and energy efficiency of various applications. By understanding the different classifications, testing methods, and practical applications of textile thermal properties, we can make informed decisions about selecting appropriate materials for specific applications. In conclusion, investing in textile materials with high thermal conductivity and low thermal diffusivity can lead to improved comfort, reduced discomfort, and increased energy efficiency in various industries.

纺织品燃烧性能概述

纺织品作为日常生活中不可或缺的物品,其燃烧性能直接关系到人们的生命财产安全,本文将围绕纺织品燃烧性能展开讨论,通过英文案例说明和表格补充说明,为您全面解析纺织品燃烧性能的重要性及其应用。

纺织品燃烧性能的重要性

纺织品燃烧性能对于保障人们的生命安全至关重要,在火灾等紧急情况下,良好的纺织品燃烧性能能够确保火势得到有效控制,防止火势蔓延,从而降低火灾带来的损失,纺织品作为日常穿着的物品,其燃烧性能也关系到人们的舒适度和健康。

纺织品燃烧性能的测试方法

纺织品燃烧性能的测试方法主要包括热释放速率测试、烟密度测试和火焰传播速度测试等,这些测试方法能够全面评估纺织品的燃烧性能,包括材料的热稳定性、火焰传播速度以及烟气排放等。

案例分析:纺织品燃烧性能的应用实例

某品牌棉质衣物

某品牌棉质衣物采用了先进的纺织技术,其面料具有较高的热稳定性,能够在高温环境下保持稳定的燃烧性能,在火灾等紧急情况下,该棉质衣物能够有效地控制火势,防止火势蔓延,该棉质衣物还具有较好的吸湿排汗功能,能够保持穿着者的舒适度。

天然纤维面料的应用

天然纤维面料如亚麻、竹纤维等具有较好的吸湿排汗性能和防火性能,这些面料在火灾等紧急情况下能够有效地吸收火焰产生的热量,防止火势进一步扩大,这些面料还具有较好的耐高温性能,能够在高温环境下保持稳定的燃烧性能。

纺织品燃烧性能的表格补充说明

纺织品燃烧性能测试参数

| 测试项目 | 测试方法 | 参数范围 | 描述 |

|---|---|---|---|

| 热释放速率(HRR) | 火焰法、烟气分析法 | 高温下测量 | 评估纺织品在高温环境下的燃烧速度和速率 |

| 烟密度(Smoke Density) | 烟气分析法 | 测量烟气中的烟雾含量 | 评估纺织品在燃烧过程中产生的烟雾量 |

| 火焰传播速度(Flame Spread) | 火焰法 | 测量火焰从点燃到完全覆盖整个织物的距离 | 评估纺织品在火焰传播过程中的速度和稳定性 |

英文案例说明

以某品牌的一款棉质衣物为例,该衣物采用了先进的纺织技术,其面料具有较高的热稳定性,在火灾等紧急情况下,该棉质衣物能够有效控制火势,防止火势蔓延,该衣物还具有较好的吸湿排汗功能,能够保持穿着者的舒适度,这一案例充分展示了纺织品燃烧性能的重要性及其应用。

纺织品燃烧性能是保障人们生命财产安全的重要指标之一,通过测试方法、案例分析和表格补充说明,本文全面解析了纺织品燃烧性能的重要性及其应用,在今后的生产和生活中,我们应该重视纺织品燃烧性能的测试和评估,选择符合安全标准的纺织品,从而保障人们的生命财产安全。

Articles related to the knowledge points of this article:

The Story of a Luxury Textile Brand 碧莱纺织品