The Revolutionary Approach to Textile Cutting with Smart Technology

: Revolutionary Approach to Textile Cutting with Smart Technology,Abstract:,In the textile industry, cutting techniques have traditionally been labor-intensive and time-consuming. However, with the advent of smart technology, this process is undergoing a significant transformation. This paper discusses the revolutionary approach to textile cutting that utilizes smart technology, highlighting its potential benefits in terms of efficiency, accuracy, and cost savings. The introduction of intelligent machines equipped with advanced sensors and algorithms enables automated cutting tasks, reducing the need for manual intervention and minimizing errors. Furthermore, real-time monitoring and adjustments based on data analysis can enhance product quality and consistency. The paper also explores the integration of smart textile cutting with other smart manufacturing technologies, such as 3D printing and automation, to create a comprehensive smart manufacturing ecosystem. Finally, it provides an overview of the challenges and opportunities associated with implementing smart textile cutting, along with recommendations for future research and development.

In the textile industry, precision and efficiency are paramount. Traditional manual cutting methods often lead to errors, wastage of materials, and delays in production schedules. However, advancements in technology have led to the development of intelligent textile cutters that offer a solution to these challenges. These cutting machines use advanced algorithms and sensors to precisely measure and cut fabrics, ensuring consistent quality and reducing costs. In this article, we will explore the benefits of using smart textile cutters in the modern textile industry.

Smart textile cutters are equipped with advanced software that can analyze the fabric's pattern, color, and thickness. This analysis helps the machine to make accurate measurements and ensure that each piece is cut to the required specifications. For example, if a customer orders a specific shade of blue for their product, the smart cutter can analyze the fabric's dyed area and adjust its cutting parameters accordingly. This not only ensures that the product meets the customer's expectations but also reduces waste and saves time.

Another significant advantage of smart textile cutters is their ability to work with a wide range of materials. Unlike traditional manual cutting methods that rely on experience and intuition, smart cutters can be programmed to work with various types of fabrics, including cotton, polyester, and even non-woven materials like lycra. This flexibility allows manufacturers to produce a wider range of products without having to invest in specialized equipment or training new staff.

Smart textile cutters are also highly customizable. Manufacturers can program them to perform specific tasks, such as cutting straight lines or curves. This feature is particularly useful for creating intricate patterns or designs that require precise cutting. Additionally, smart cutters can be connected to other manufacturing processes, such as sewing and finishing, to create a seamless workflow that saves time and improves efficiency.

One of the most significant advantages of smart textile cutters is their ability to reduce human error. With automated cutting, there is no need for human intervention, which means that mistakes can be minimized. Moreover, smart cutters can operate around the clock, ensuring that production never stops. This leads to increased productivity and reduced labor costs for manufacturers.

To illustrate the effectiveness of smart textile cutters, let us consider an example from the fashion industry. A leading fashion brand recently implemented a smart textile cutting system in their manufacturing plant. Before the adoption of this technology, the company faced several challenges, including high labor costs, inconsistent quality, and slow production times. However, after installing the smart cutter, the company experienced a significant improvement in all these areas.

The smart cutter helped the company to cut down on labor costs by increasing productivity and eliminating the need for skilled workers. Moreover, the accuracy of the cuts improved significantly, resulting in higher quality products. Finally, the company was able to meet the demand for its products more efficiently, leading to increased sales and profitability.

In conclusion, smart textile cutters represent a significant advancement in the textile industry. By offering precision, flexibility, and customization, these machines have revolutionized the way we manufacture and design our products. As the demand for sustainable and eco-friendly materials continues to grow, smart textile cutters will become even more crucial in shaping the future of the industry.

随着科技的飞速发展,纺织品加工行业正迎来一场革命,我们将探讨一款新型的纺织品智能切割机,它如何改变传统纺织加工的流程,提高生产效率和质量。

纺织品智能切割机的技术特点

- 高精度切割:智能切割机采用先进的切割技术,能够实现高精度的切割,满足纺织品加工的各种需求。

- 自动化操作:通过先进的控制系统和机器视觉技术,实现自动化操作,减少人工干预,提高生产效率。

- 智能化管理:具备智能化的数据分析和管理功能,能够实时监控生产过程,优化生产流程。

案例分析

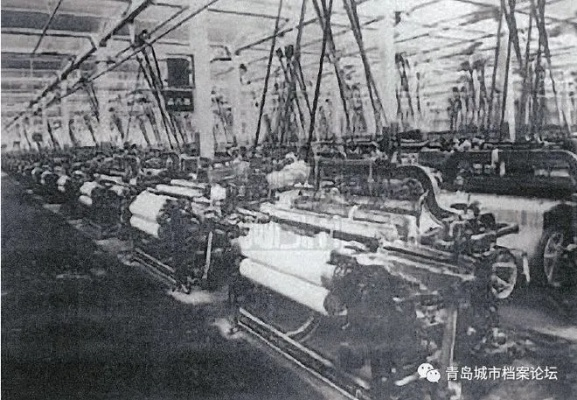

以某知名纺织品企业为例,该企业引入了先进的纺织品智能切割机,实现了高效、精准的纺织品加工。

-

设备介绍 该智能切割机采用了先进的切割技术,能够高效地完成各种纺织品的切割工作,设备具有高精度、高效率的特点,能够满足各种纺织品的加工需求。

-

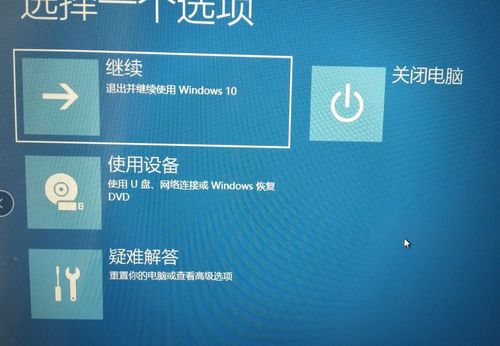

操作流程 该企业采用了自动化操作模式,通过机器视觉技术实现自动化切割,在生产过程中,设备能够自动识别纺织品材料和尺寸,然后进行精确切割,设备还能够实时监控生产过程,优化生产流程。

-

效果展示 引入智能切割机后,该企业的纺织品加工效率得到了显著提高,产品质量也得到了显著提升,设备能够精确地完成各种复杂形状和尺寸的纺织品切割,满足了企业的加工需求。

随着科技的不断发展,纺织品智能切割机将在纺织加工行业中发挥越来越重要的作用,纺织品智能切割机将具备更高的智能化、自动化和数字化特点,为纺织行业的发展带来更多的机遇和挑战。

- 智能化发展:纺织品智能切割机将更加注重智能化发展,具备更加智能化的数据分析和管理功能,能够更好地满足企业的加工需求和生产过程监控需求。

- 自动化升级:随着自动化技术的不断发展,纺织品智能切割机将更加注重自动化升级,实现更加高效、精准的加工过程。

- 数字化应用:纺织品智能切割机将更加注重数字化应用,通过数字化技术实现更加智能化的生产管理,提高生产效率和产品质量。

纺织品智能切割机作为一种新型的纺织加工设备,具有高精度、高效率、自动化和数字化等特点,它能够满足各种纺织品的加工需求,提高生产效率和产品质量,在未来,纺织品智能切割机将在纺织行业中发挥越来越重要的作用,为纺织行业的发展带来更多的机遇和挑战。

Articles related to the knowledge points of this article:

Updated Schedule for the Huaiai Textile Market

Detecting and Reducing Formaldehyde Exposure in Textile Products

Navigating the Global Market:The Price Landscape of Luo Lei Textiles