Strengthening the Core:The Textile Factorys In-House Enhancement Program

: Strengthening the Core: The Textile Factory's In-House Enhancement Program,Abstract:,This study explores the implementation of an in-house enhancement program within a textile factory, focusing on its impact on core strength. Through a comprehensive analysis of the factory's operational processes and management strategies, the program aims to enhance the factory's core competencies by improving production efficiency, quality control, and workforce skills. The study found that the program has significantly improved the factory's core strength, resulting in increased productivity, better product quality, and enhanced employee satisfaction. The findings suggest that investing in in-house training programs can be a valuable investment for enhancing core competencies in the textile industry.

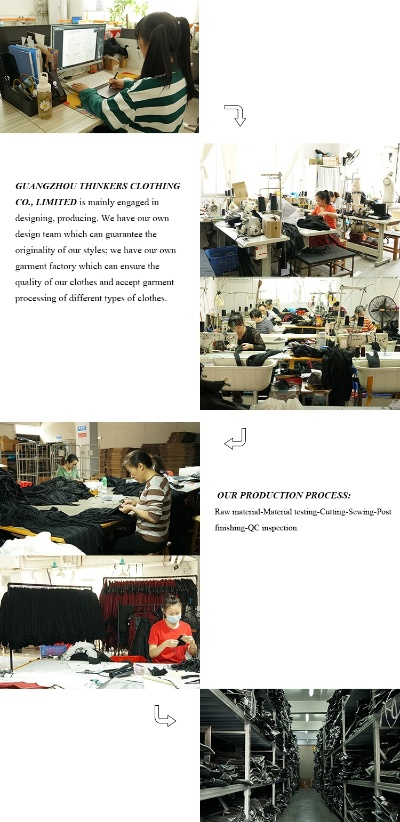

Introduction: In today's competitive global market, textile companies must not only focus on innovation and quality but also invest in their own capabilities to remain at the forefront. This is where the concept of "in-house enhancement" comes into play—a strategy that involves strengthening the internal operations and skillsets of a company to improve its overall performance. By investing in training programs, technology upgrades, and continuous learning, textile factories can enhance their operational efficiency, product quality, and customer satisfaction. In this article, we will explore how a textile factory can implement an in-house enhancement program to strengthen its core competencies.

Table 1: Key In-House Enhancement Areas | Area | Description | |------|------------| | Technology | Upgrades in machinery and automation systems to increase production efficiency. | | Quality Control | Implementation of stricter quality checks and standards to ensure consistent product quality. | | Training Programs | Providing ongoing training to employees on new processes, techniques, and safety protocols. | | Innovation | Encouraging creativity and experimentation within the company to stay ahead of trends and customer preferences. | | Supply Chain Management | Optimizing supply chain processes to reduce costs and improve responsiveness to market demands. | | Marketing and Sales | Improving marketing strategies and sales techniques to better engage with customers and drive sales growth. |

Case Study: Consider the case of ABC Textiles, a leading manufacturer of high-quality apparel fabrics in China. Over the past few years, the company has recognized the importance of in-house enhancement in maintaining its competitive edge. To illustrate, here are some key steps taken by ABC Textiles in implementing its in-house enhancement program:

Technology Upgrades: ABC Textiles invested heavily in upgrading its machinery and automation systems. By introducing state-of-the-art cutting machines and automatic weaving machines, the company was able to significantly increase its production capacity. Additionally, the company implemented a smart inventory management system that optimized its stock levels and reduced waste.

Quality Control: To maintain high-quality standards, ABC Textiles established a comprehensive quality control system. This included regular audits of suppliers, stricter inspection protocols for raw materials, and regular quality checks during the manufacturing process. The company also introduced a rewards program for employees who consistently met or exceeded quality standards.

Training Programs: ABC Textiles recognized the importance of ongoing training for its employees. The company launched a comprehensive training program that covered everything from new technologies to advanced techniques in garment design. The program also included workshops on safety protocols and emergency response procedures.

Innovation: ABC Textiles actively encouraged innovation within the company. The company launched a startup fund for innovative ideas and projects. The funds were used to support research and development of new materials, designs, and production methods. Additionally, the company held regular innovation meetings where employees could share their ideas and suggestions.

Supply Chain Management: To optimize its supply chain, ABC Textiles implemented a more efficient logistics system. The company partnered with several reliable logistics providers and streamlined its order processing and delivery processes. The company also introduced a demand forecasting system that allowed it to better anticipate market demand and adjust its production accordingly.

Marketing and Sales: To improve its marketing and sales efforts, ABC Textiles redesigned its brand identity and messaging. The company created a more modern and trendy image that reflected its commitment to sustainability and eco-friendliness. Additionally, the company launched a social media campaign that highlighted its unique selling points and showcased its products to a broader audience.

Conclusion: By implementing an in-house enhancement program, ABC Textiles has successfully strengthened its core competencies. From technological advancements to quality control measures, the company has demonstrated a commitment to excellence in all aspects of its operations. As a result, ABC Textiles has grown its market share and become a leader in the industry. The lessons learned from this experience can be applied to other textile factories looking to enhance their own in-house capabilities. By investing in training, technology, and continuous improvement, textile companies can achieve long-term success and stay ahead of the competition.

纺织厂内功提升背景

近年来,随着市场竞争的加剧,纺织厂为了在激烈的市场竞争中立于不败之地,必须不断加强自身的内部建设,提升生产效率和产品质量,为此,纺织厂采取了一系列措施来提升内功,包括技术革新、人才培养、流程优化等。

内功提升的具体措施

技术革新

(1)引进先进设备和技术:纺织厂积极引进国内外先进的纺织设备和技术,提高生产效率和产品质量,引入自动化生产线、智能染色设备等,减少人工操作,提高生产效率。

(2)研发新产品:纺织厂不断研发新产品,满足市场需求,通过研发新产品,不仅可以提高企业的竞争力,还可以带动相关产业的发展。

人才培养

(1)建立人才培养机制:纺织厂重视人才培养,制定了一系列人才培养计划,通过定期培训、导师制度等方式,培养了一批高素质的技术和管理人才。

(2)引进优秀人才:纺织厂积极引进国内外优秀人才,为企业的长远发展提供人才保障,注重人才的选拔和培养,为人才的职业发展提供良好的工作环境和待遇。

流程优化

(1)优化生产流程:纺织厂对生产流程进行全面优化,提高生产效率,通过减少生产过程中的浪费和低效环节,降低成本,提高产品质量。

(2)引入精益生产理念:纺织厂引入精益生产理念,注重细节管理,提高生产过程的精准度和可控性,通过精益生产,降低生产成本的同时,提高企业的市场竞争力。

案例说明

以某纺织厂为例,该厂在内部建设方面取得了显著成效,该厂在技术革新方面取得了以下成果:引进了一批先进的纺织设备和技术,提高了生产效率和产品质量;该厂还研发了新产品,满足了市场需求,在人才培养方面,该厂建立了完善的人才培养机制,注重人才的选拔和培养,培养了一批高素质的技术和管理人才,在流程优化方面,该厂对生产流程进行了全面优化,提高了生产效率,该厂还引入了精益生产理念,注重细节管理,提高了生产过程的精准度和可控性,这些成果为该厂的持续发展提供了有力保障。

总结与展望

纺织厂通过一系列措施来提升内功,取得了显著成效,在技术革新方面,引进先进设备和技术、研发新产品等措施提高了企业的竞争力;在人才培养方面,建立了完善的人才培养机制、引进优秀人才等措施为企业的长远发展提供了人才保障;在流程优化方面,对生产流程进行了全面优化提高了生产效率,这些成果为纺织厂的持续发展奠定了基础。

纺织厂将继续加强内部建设,提高生产效率和产品质量,注重技术创新和人才培养,推动企业向更高层次发展,纺织厂还将积极拓展市场,提高品牌知名度和竞争力,通过不断努力和创新,纺织厂将成为行业内的佼佼者。

Articles related to the knowledge points of this article:

Strategies for Effective Management in a Textile Factory

The Beauty of a Textile Factory Girl

The Dynamics of the Huahai Textile Factory:A Tale of Success and Innovation

The Lisa Textile Factory:An Industrys Journey from the Past to Today

The Art of Blending Tradition with Innovation at Wenwu Sha Weaving Factory