The Chemical Analysis of Textiles:A Comprehensive Guide

"The Chemical Analysis of Textiles: A Comprehensive Guide" is a comprehensive guide to the chemical analysis of textiles. It covers all aspects of textile chemistry, including fiber characterization, dyeing and finishing processes, and environmental considerations. The book provides detailed information on the use of various analytical techniques such as Fourier-transform infrared spectroscopy (FTIR), gas chromatography (GC), and high-performance liquid chromatography (HPLC). Additionally, it includes practical tips for conducting effective chemical analyses and interpreting results. Overall, this guide is an essential resource for anyone working with textiles, from researchers to industry professionals."

Introduction: Textiles are an integral part of our daily lives, and their quality is often determined by the chemical composition of the materials used in their production. In this article, we will explore the various types of chemicals used in textile manufacturing, their impact on the fabric's properties, and how to perform chemical tests to ensure that the products meet industry standards. We will also provide some practical examples of chemical testing and offer tips for conducting effective tests.

Types of Chemicals Used in Textile Manufacturing:

- Fabric Dyes: These are colorants added to textiles to create vibrant colors. They can be natural or synthetic and come in various shades and hues.

- Finishing Agents: These chemicals are used to enhance the appearance and texture of textiles, such as softeners, anti-static agents, and flame retardants.

- Antimicrobial Agents: These chemicals prevent bacteria and fungi growth on textiles, making them more hygienic and resistant to wear and tear.

- Waterproofing Agents: These chemicals improve the water resistance of textiles, making them suitable for outdoor use.

- Emulsifiers: These chemicals help in the formation of stable emulsions during the dyeing process, ensuring even distribution of color across the fabric.

- pH Regulators: These chemicals adjust the pH level of the dye bath to achieve optimal dye uptake and color stability.

- Sizing Agents: These chemicals thicken the fabric, making it easier to handle and shape.

- Stabilizers: These chemicals protect the fibers from environmental factors like UV radiation, heat, and moisture, preventing fading and shrinkage.

Impact of Chemicals on Textile Properties: The choice and concentration of chemicals used in textile manufacturing can have a significant impact on the fabric's performance and appearance. For example, excessive use of dyes can lead to discoloration, while too little can result in dullness. Finishing agents can affect the fabric's softness, elasticity, and breathability, while antimicrobial agents can reduce the risk of bacterial growth. Waterproofing agents can improve the fabric's durability, while emulsifiers can enhance the dye's adhesion to the fibers. pH regulators can help maintain the fabric's pH balance, while sizing agents can make the fabric more manageable. Stabilizers can protect the fabric against environmental stresses, ensuring its longevity.

Chemical Testing Methods: To ensure that textiles meet industry standards, chemical testing methods must be employed. Some common methods include:

- Spectrophotometry: This method uses light absorption to determine the concentration of dyes in the fabric. It is a quick and convenient way to assess the color intensity and uniformity of the dyed fabric.

- Colorimetry: This method involves measuring the color difference between the fabric and a standard sample using a spectrophotometer. It is useful for determining the effectiveness of finish agents and antimicrobial agents.

- Dyeing Resistance Testing: This method evaluates the fabric's ability to resist dye transfer during washing and exposure to sunlight. It is crucial for outdoor wear and protective clothing.

- Moisture Resistance Testing: This method assesses the fabric's ability to retain its shape and color after being exposed to moisture. It is important for sportswear and outdoor apparel.

- pH Testing: This method measures the fabric's pH level using a pH meter. It is essential for maintaining the fabric's pH balance and preventing fading.

- Sizing Agent Testing: This method checks the amount of sizing agent present in the fabric using a gravimetric method or a densitometer. It is important for garments that require smooth handling and shaping.

- Stabilizer Testing: This method evaluates the fabric's ability to resist environmental stresses using a thermal analysis technique. It is crucial for high-performance fabrics.

Practical Examples: One practical example of chemical testing is the dyeing resistance test conducted on a shirt fabric. The shirt is first subjected to a dye bath containing different concentrations of dyes and then washed with detergent to simulate normal use conditions. The color difference between the unwashed and washed samples is measured using a spectrophotometer to determine the dye's resistance to washing and fading.

Tips for Conducting Effective Tests:

- Choose appropriate test methods based on the type of fabric and the purpose of the test.

- Use standardized test protocols to ensure consistency and reproducibility.

- Analyze the results carefully to identify any deviations from expected values.

- Consider the fabric's intended use and environment when selecting appropriate test methods.

- Keep records of all test results and compare them with industry standards to ensure compliance.

- Regularly update knowledge about new chemicals and test methods to stay up-to-date with industry trends.

Conclusion: Textiles are complex products that rely heavily on the chemical composition of their materials. By understanding the impact of different chemicals on textile properties and employing appropriate testing methods, manufacturers can ensure that their products meet industry standards and provide a high-quality experience to consumers. With careful consideration of each fabric's unique needs and the potential environmental impacts of chemical usage, textile manufacturers can continue to innovate and improve the overall quality of their products.

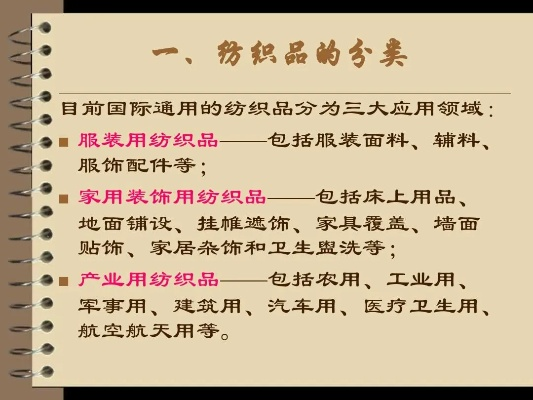

纺织品化学检测概述

随着纺织行业的快速发展,纺织品的质量和安全性越来越受到人们的关注,纺织品化学检测作为保障纺织品质量的重要手段,其重要性不言而喻,本文将围绕纺织品化学检测的主题,从多个方面进行详细阐述。

纺织品化学检测的重要性

纺织品化学检测在保障纺织品质量方面发挥着至关重要的作用,通过纺织品化学检测,可以有效地识别和评估纺织品的成分、性能、安全性等方面的问题,从而为纺织品的生产、销售和质量控制提供有力的依据,纺织品化学检测还可以为纺织品的研发、改进和创新提供科学依据,推动纺织行业的发展。

纺织品化学检测的方法和流程

纺织品化学检测的方法和流程主要包括样品采集、样品处理、化学分析等步骤,样品采集时,需要选择具有代表性的样品,确保样品的真实性和准确性,样品处理时,需要按照一定的标准和方法进行处理,以确保检测结果的准确性和可靠性,化学分析是纺织品化学检测的核心步骤,需要使用专业的化学试剂和仪器进行检测,包括元素分析、纤维成分分析、染色牢度测试等。

案例分析

以某知名纺织品牌为例,对其纺织品化学检测的过程进行案例分析,该品牌在生产过程中,对每一批次的纺织品都进行了严格的化学检测,他们选择了具有代表性的样品进行采集和处理,他们使用专业的化学试剂和仪器进行化学分析,包括元素分析、纤维成分分析、染色牢度测试等,根据检测结果,他们发现了一些潜在的质量问题,并及时采取了相应的措施进行改进。

纺织品化学检测的注意事项

在进行纺织品化学检测时,需要注意以下几点事项,要确保样品的选择具有代表性,以确保检测结果的准确性,要严格按照标准和方法进行样品处理和化学分析,以确保检测结果的可靠性和准确性,在进行纺织品化学检测时,还需要注意环境保护和安全操作,确保检测过程的安全性和合规性。

纺织品化学检测的未来发展趋势

随着纺织行业的不断发展,纺织品化学检测的未来发展趋势将更加注重智能化、精细化、多元化等方面,智能化方面,将使用更多的智能化技术和设备进行纺织品化学检测,提高检测效率和准确性,精细化方面,将更加注重纺织品化学检测的细节和精度,确保检测结果的准确性和可靠性,多元化方面,将更加注重纺织品的功能性和环保性等方面的要求,推动纺织品的创新和发展。

纺织品化学检测是保障纺织品质量的重要手段,其重要性不言而喻,通过纺织品化学检测的方法和流程、案例分析以及未来发展趋势等方面的介绍,我们可以更好地了解纺织品化学检测的重要性和应用前景,我们也应该注重纺织品化学检测的过程和细节,确保检测结果的准确性和可靠性,为纺织品的生产、销售和质量控制提供有力的依据。

Articles related to the knowledge points of this article:

纺织品CCS:A Comprehensive Guide to Global Carbon Capture Standards for Textiles

Home Textiles:The New Frontier in Interior Design

A Comprehensive Guide to Textile Certifications

Functional Textiles:A Global Perspective on Research and Innovation