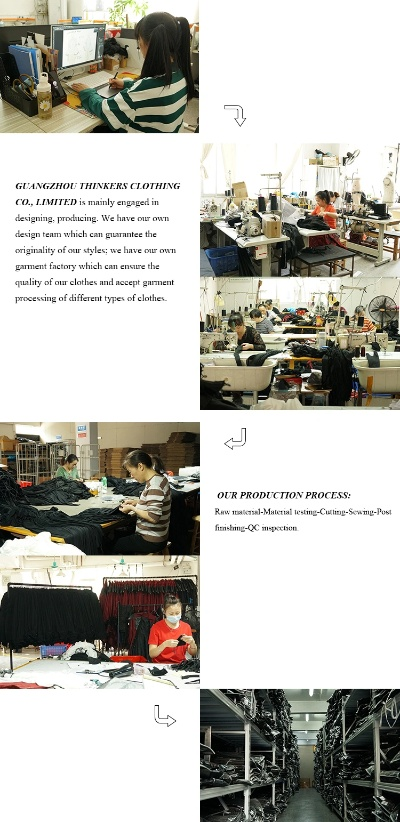

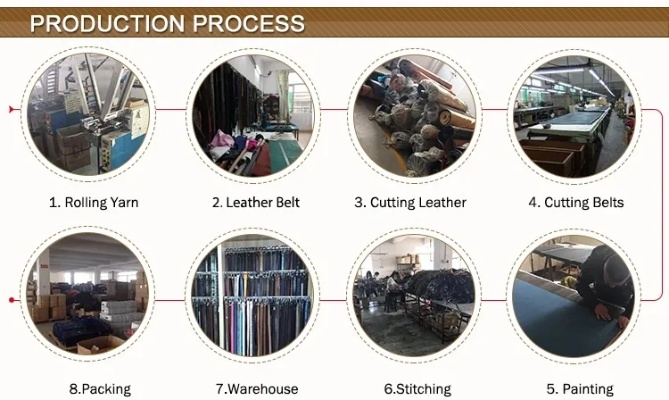

The Fabrication Process in a Textile Workshop

The fabrication process in a textile workshop involves several key steps, from raw material preparation to the final product assembly. The first step is the selection of high-quality yarns and fibers, which are then processed into thread or strands. These are then woven or knitted into a base fabric, which is the foundation for any textile product.,Once the base fabric is complete, it undergoes further processing, including dyeing and finishing. Dyeing involves applying colorants to the fabric, while finishing involves adding embellishments such as embroidery, lace, or other decorative elements.,Finally, the completed textile product is packaged and shipped to its intended destination, ready for use by customers around the world. The entire process from start to finish requires careful attention to detail and meticulous craftsmanship, ensuring that each piece of clothing or textile is of the highest quality possible.

Introduction: In the textile industry, the fabrication process is a crucial step that involves various stages of production. From raw materials to finished products, every step is essential for creating high-quality textiles that meet the demands of consumers. In this video, we will explore the different stages of the fabrication process and how they contribute to the final product.

Stage 1: Raw Materials Preparation The first stage of the fabrication process is the preparation of raw materials. This includes selecting the right type of yarn, fiber, and other materials required for the textile product. For example, if we are making a cotton shirt, we would need to select high-quality cotton yarn and fiber.

Stage 2: Yarn Production After preparing the raw materials, the next step is yarn production. This involves spinning the yarn into strands using a spinneret. The quality of the yarn produced depends on factors such as the speed of the spindle, the temperature of the yarn, and the consistency of the yarn.

Stage 3: Weaving or Knitting Once the yarn is ready, it is then used to create textile products through weaving or knitting. Weaving involves interlocking threads to form a fabric while knitting involves looping individual threads together. Both techniques require careful attention to detail to ensure the final product is of high quality.

Stage 4: Dyeing and Printing After weaving or knitting, the next step is dyeing and printing. This involves applying color to the fabric to give it a unique look and feel. The quality of the dye applied depends on factors such as the type of dye used, the concentration of the dye, and the temperature at which it is applied.

Stage 5: Finishing Finally, the fabric is ready for finishing. This includes adding additional features such as embroidery, lacework, or embellishments. The quality of the finish depends on factors such as the skill of the finisher and the materials used.

Case Study: One example of a successful textile product is a luxurious silk scarf. The fabrication process involved selecting high-quality silk yarn, producing the yarn through spinning, weaving it into a scarf, dyeing it with a vibrant color, and finally finishing it with intricate embroidery. The result was a scarf that was both beautiful and functional, making it a popular item among fashion enthusiasts.

Conclusion: The fabrication process in a textile workshop is a complex and multi-step process that requires careful attention to detail. Each stage plays a vital role in creating high-quality textile products that meet consumer demand. By following these steps, businesses can produce products that not only look great but also provide functionality and value to their customers.

我们参观了一个纺织品车间,通过视频记录了其生产流程和设备情况,车间内,工人们正在忙碌地操作各种纺织机械,生产出高质量的纺织品,下面是一篇以纺织品车间视频为主题的英文口语化内容。

视频开头,画面展示车间宽敞明亮的环境,各种纺织机械整齐排列,工人们正在有条不紊地进行生产工作,随后,视频详细展示了车间的工作流程和设备情况。

设备介绍

- 纺织机械:视频中展示了多种纺织机械,包括但不限于织布机、染整设备、熨烫设备等,这些设备都是现代化的,能够高效地完成纺织品的生产。

- 自动化程度:视频中可以看到许多设备都配备了自动化控制系统,大大提高了生产效率。

- 质量控制:视频中展示了严格的质量控制流程,从原材料到成品都有严格的质量检测标准。

工作流程说明

- 原料准备:视频中可以看到工人们正在对原料进行清洗、整理等准备工作。

- 织布:在织布环节,工人们使用先进的织布机进行织布,确保织物的质量和厚度。

- 染色与整理:在染色与整理环节,工人们使用染料和整理剂对纺织品进行染色和整理,使其具有特定的颜色、质地和图案。

- 成品检验:在成品检验环节,工人们会对成品进行质量检测,确保其符合标准。

案例分析

在纺织品车间视频中,我们可以看到许多成功的案例,某家纺织品企业的生产线采用了先进的纺织机械和技术,大大提高了生产效率和质量,该企业还注重质量控制和员工培训,使得员工能够熟练掌握纺织品的生产流程和技能,该企业还注重环保和可持续发展,采用环保材料和技术,使得生产过程更加绿色和可持续。

补充说明

为了更好地说明纺织品车间视频中的情况,我们可以使用英文表格进行补充说明,以下是英文表格:

纺织品车间视频补充说明 | 具体描述 | | --- | --- | | 设备情况 | 现代化纺织机械、自动化控制系统、严格的质量控制流程 | | 工作流程 | 原料准备、织布、染色与整理、成品检验 | | 成功案例 | 采用先进纺织机械和技术提高生产效率和质量 | | 环境与氛围 | 宽敞明亮的车间环境、整洁的设备排列 | | 员工培训与环保意识 | 注重员工培训、环保材料和技术使用 |

通过纺织品车间视频的观看,我们了解了该企业的生产流程和设备情况,以及其在质量控制、员工培训等方面的做法,我们也看到了许多成功的案例和环保意识,纺织品车间的生产过程需要注重高效、环保和可持续发展等方面的工作。

Articles related to the knowledge points of this article:

Unveiling the Dynamics of Lian Tai Textiles A Comprehensive Analysis

Top Ten Textile Brands in the Rankings

Exploring the World of Quality Textiles with Jia Tien Textiles