The Multifaceted World of Textile Inspection

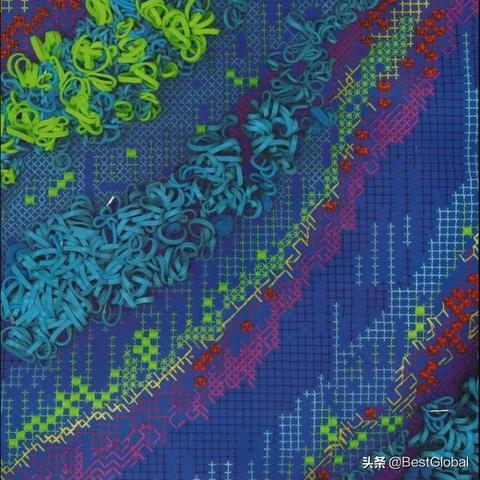

The textile inspection industry is a complex and multifaceted domain that encompasses various aspects of quality control, material testing, and product evaluation. This field involves the use of specialized tools and techniques to ensure that textile products meet certain standards and requirements. Textile inspection is crucial for ensuring the safety and quality of consumer goods, as well as for maintaining the integrity of the textile industry itself.,One of the primary functions of textile inspection is to detect any defects or flaws in the fabric. This includes identifying issues such as color variations, pattern misalignment, and thread breakage. Inspectors also evaluate the overall appearance of the textile, assessing factors like uniformity, thickness, and density.,In addition to physical inspections, textile inspection also involves chemical analysis to determine the composition of the fabric. This can involve testing for specific materials or dyes used in the production process. Chemical analysis helps to identify any impurities or contaminants that may affect the performance or durability of the textile.,Overall, textile inspection is a critical component of the textile industry, providing assurance that products are safe, reliable, and of high quality. With advances in technology and automation, the industry continues to evolve, making it more efficient and effective in its efforts to ensure the quality of textile products.

Introduction: In the vast world of textiles, quality control is paramount. From ensuring materials meet standards to detecting defects in fabrics, textile inspection plays a crucial role in safeguarding consumer safety and maintaining the integrity of the industry. This talk will delve into the various aspects of textile inspection, from the technicalities of testing to real-world cases where this process has made a difference. Let's explore the complexities of inspecting textiles and how they contribute to our daily lives.

Technical Aspects: Textile inspection involves a range of methods and tools that help identify flaws, imperfections, or contaminants in textile materials. Here's a table summarizing some common techniques used in textile inspection:

| Technique | Purpose |

|---|---|

| Structural Testing | Identify any physical damage or weaknesses in fabrics. |

| Chemical Analysis | Determine if the fabric contains harmful substances or pollutants. |

| Microbial Testing | Check for microbial growth on textiles, which can lead to infections. |

| Dye Testing | Evaluate the colorfastness of dyes applied to textiles. |

| Burn Testing | Assess the resistance of fabrics to flames. |

| Tear Testing | Measure the strength of fabrics under tension. |

| Wet Stretch Testing | Assess the elasticity and resilience of textiles. |

| Texture Testing | Measure the feel and appearance of fabrics. |

Real-World Case Study: Consider the case of a garment manufacturer who was facing significant recalls due to defective fabrics. Through rigorous inspections, they discovered that the issue stemmed from an undetected chemical contamination in the dye process. The company then implemented a comprehensive quality assurance program, including regular training for its staff and stricter regulations for suppliers. This change led to a significant reduction in such incidents and improved customer trust.

Advanced Technologies: As technology advances, so do the tools available for textile inspection. Today, we have machines that can analyze fabrics with incredible precision. For instance, computer-controlled scanning electron microscopes (SEMs) can provide detailed images of surface features that might otherwise be missed during manual inspection. Additionally, machine learning algorithms can be trained to identify patterns of defects that are difficult to spot by human eyes.

Conclusion: Textile inspection is a critical component of the textile industry, ensuring products meet safety and quality standards. By understanding the technical aspects and real-world implications of these inspections, manufacturers can take proactive measures to prevent potential issues before they occur. As technology continues to evolve, so too must the methods and tools used in textile inspection. It is essential for businesses to stay informed about the latest advancements and incorporate them into their processes to maintain their competitive edge and ensure the well-being of consumers.

在纺织品检验过程中,我们确保每一件产品都符合质量标准,以确保消费者的安全和舒适,本文将详细介绍纺织品检验的基本流程、注意事项以及案例分析。

纺织品检验的基本流程

样品准备

在开始检验之前,我们需要准备好待检验的纺织品样品,样品应具有代表性,以确保检验结果的准确性。

实验室检测

实验室检测是纺织品检验的关键环节,我们使用各种检测仪器和方法,如拉力测试、尺寸测量、耐久性测试等,对样品进行全面检查。

数据记录与分析

检测结果应详细记录,并进行深入分析,我们通过数据分析,了解纺织品的质量状况,为后续处理提供依据。

纺织品检验的注意事项

严格遵守检验标准

在检验过程中,我们必须严格遵守国家或行业标准,确保检验结果的准确性和可靠性。

样品保存与处理

样品在运输和保存过程中应保持良好状态,避免样品受到损坏或污染,对于特殊样品,应按照相关规定进行处理。

注意安全防护

在进行纺织品检验时,我们必须注意安全防护,避免样品受到有害物质的污染,穿戴适当的防护用品,确保检验过程的安全。

案例分析

以某品牌纺织品为例,进行案例分析,该品牌在纺织品检验过程中,严格按照国家标准进行操作,确保产品质量,以下是具体的案例分析:

样品准备与检测过程

该品牌提供了具有代表性的纺织品样品,使用先进的检测仪器和方法进行全面检查,检测过程中,严格按照国家标准进行操作,确保检验结果的准确性。

数据记录与分析结果

经过检测,该品牌纺织品的质量符合国家标准要求,数据分析显示,该品牌纺织品的各项性能指标均达到或超过行业标准,该品牌还注重产品的环保性能和安全性,确保消费者在使用过程中的安全和舒适。

纺织品检验是确保产品质量的重要环节,在纺织品检验过程中,我们必须严格遵守国家或行业标准,确保检验结果的准确性和可靠性,我们还应注意安全防护,确保检验过程的安全和顺利,通过案例分析,我们可以看到,严格按照国家标准进行操作,注重产品的环保性能和安全性,是提高纺织品质量的重要措施。

Articles related to the knowledge points of this article:

A Comprehensive Guide to Purchasing Inventory Textiles in Zhejiang

The Fabric of Innovation:An Insight into Kashka Textiles

Global Trade Landscape of Textiles Between China and the US

The Incredible World of Materials Made from Tree Bark

Exploring the Rich Tapestry of Textiles from Nantong Mei Nián Hua