Strategies for Effective Textile Factory Management

: Strategies for Effective Textile Factory Management,In the textile industry, effective management is crucial for ensuring production efficiency, quality control, and cost-effectiveness. This paper outlines several strategies that can be employed to improve textile factory management. Firstly, regular training and development programs should be implemented to enhance staff skills and knowledge. Secondly, a comprehensive inventory system should be established to monitor raw materials and finished products accurately. Thirdly, advanced technology and automation should be integrated into the manufacturing process to increase efficiency and reduce errors. Fourthly, a strong communication network should be established between different departments to ensure timely information sharing. Finally, regular audits and evaluations should be conducted to identify areas for improvement and make necessary adjustments. By implementing these strategies, textile factories can achieve better performance and competitiveness in the market.

Introduction to Textile Factory Management

Textile factories are the backbone of the global textile industry, producing a wide range of products such as clothing, home textiles, and industrial fabrics. These factories are complex systems that require effective management to ensure efficiency, quality, and profitability. In this article, we will explore some key strategies for managing textile factories effectively.

Define Clear Objectives

The first step in managing a textile factory is to define clear objectives. These should be specific, measurable, achievable, relevant, and time-bound (SMART). For example, your objectives could be to reduce production costs by 10%, increase product quality by 5%, or improve customer satisfaction by 20%. By setting clear goals, you can measure your progress and make informed decisions about how to improve your operations.

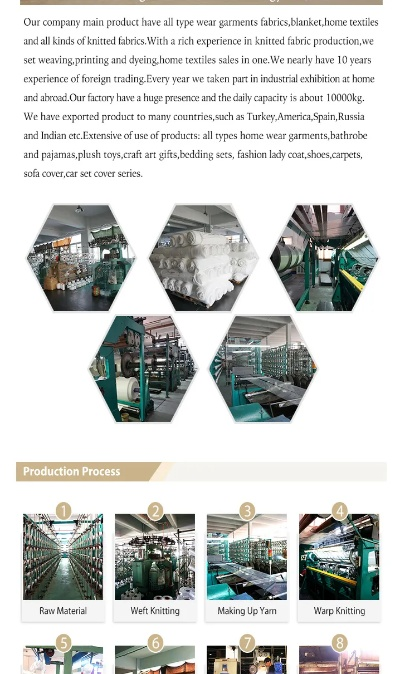

Implement a Comprehensive Production System

A well-designed production system is essential for efficient textile factory management. This system should include detailed plans for each stage of the production process, from raw material procurement to finished product assembly. You should also have a system for tracking inventory levels, monitoring production schedules, and ensuring that all equipment is functioning properly. A good example of a comprehensive production system is the Ford Motor Company's assembly line, which has been used successfully in many textile factories around the world.

Utilize Technology Wisely

Technology plays a crucial role in modern textile factory management. Advances in automation, robotics, and digitalization can greatly enhance efficiency and reduce errors. However, it's important to choose technology that fits your specific needs and budget. For example, a company may choose to invest in automated cutting machines to streamline the cutting process, while another may opt for a more labor-intensive approach with manual cutting techniques.

Develop a Quality Control Program

Quality control is critical in ensuring that your textile products meet customer expectations. A quality control program should include regular inspections of finished goods, testing of raw materials, and training of employees on proper procedures. Additionally, you should establish strict standards for defective products and implement corrective actions when necessary. An example of a successful quality control program is the Nike Corporation's commitment to excellence in manufacturing its sportswear products, which has helped them maintain a strong reputation in the market.

Foster a Culture of Continuous Improvement

Finally, it's essential to cultivate a culture of continuous improvement within your textile factory. This means encouraging employees to identify areas where they can improve processes and results, as well as providing resources and support for innovation. By fostering a culture of innovation, you can stay ahead of the competition and adapt to changing market conditions. A prime example of a company that promotes continuous improvement is Toyota Motor Corporation, which has developed a culture of "kaizen" that encourages employees to identify and implement small improvements that can lead to significant cost savings and increased productivity.

Conclusion

Managing a textile factory requires a multifaceted approach that encompasses clear objectives, a comprehensive production system, the use of technology wisely, a quality control program, and a culture of continuous improvement. By implementing these strategies, you can not only improve efficiency and profitability but also enhance the overall quality of your products and services. Remember, effective textile factory management is an ongoing process that requires constant attention and adjustments based on changing market conditions and technological advancements.

随着纺织行业的快速发展,纺织厂的管理工作显得尤为重要,为了提升纺织厂的运营效率和管理水平,我们制定了一套纺织厂管理模板,本篇文章将详细介绍该模板的主要内容,并结合实际案例进行说明。

目标与原则

纺织厂管理模板旨在通过规范化、系统化的管理手段,提高生产效率、降低成本、提升产品质量,确保企业的可持续发展。

(1)生产计划与调度:根据市场需求和产能情况,制定合理的生产计划,合理安排生产进度。 (2)原料采购与质量控制:选择优质原料,确保原料质量符合标准,建立严格的质量控制体系。 (3)设备维护与检修:定期对设备进行维护和检修,确保设备正常运行。 (4)员工培训与考核:定期对员工进行培训,提高员工技能水平,建立完善的考核机制。 (5)环境与安全:遵守相关环保法规,确保生产环境安全。

实际案例分析

某纺织厂生产管理实践

某纺织厂在生产过程中,采用了以下管理措施:

(1)制定详细的生产计划,根据市场需求和产能情况,合理安排生产进度。 (2)严格把控原料采购质量,选择优质原料供应商,建立原料质量检测体系。 (3)建立设备维护与检修制度,定期对关键设备进行维护和检修,确保设备正常运行。 (4)加强员工培训,提高员工技能水平,定期开展技能竞赛和培训活动。 (5)遵守相关环保法规,确保生产环境安全。

通过以上实践,该纺织厂的生产效率得到了显著提升,产品质量也得到了提高,该厂还获得了良好的市场口碑和客户满意度。

纺织厂管理改进措施

在实际管理中,某纺织厂也遇到了一些问题,如生产计划执行不力、原料采购成本波动大等,为了解决这些问题,该厂采取了以下改进措施:

(1)引入ERP系统,实现生产计划的实时监控和调整。 (2)加强与原料供应商的沟通与合作,建立稳定的供应链关系。 (3)建立严格的原料质量控制体系,确保原料质量稳定可控。 (4)开展员工绩效考核和激励机制,提高员工工作积极性和满意度。 (5)加强环境与安全监管,确保生产环境符合相关法规要求。

通过以上改进措施的实施,该纺织厂的管理水平得到了显著提升,生产效率得到了进一步提高,该厂还获得了更多的市场份额和客户信任。

表格补充说明

以下是纺织厂管理模板中的表格补充说明:

纺织厂管理模板主要内容概览表 | 描述 | 具体措施 | 实例说明 | | --- | --- | --- | --- | | 生产计划与调度 | 根据市场需求和产能情况制定生产计划 | 制定详细的生产计划、合理安排生产进度 | 某纺织厂根据市场需求和产能情况制定详细的生产计划并合理安排生产进度 | | 原料采购与质量控制 | 选择优质原料并建立严格的质量控制体系 | 选择优质原料供应商、建立原料质量检测体系 | 某纺织厂选择优质原料供应商并建立严格的原料质量检测体系以确保产品质量 | | 设备维护与检修 | 定期对关键设备进行维护和检修 | 建立设备维护与检修制度、制定维护和检修计划 | 某纺织厂定期对关键设备进行维护和检修以确保设备正常运行 | | 员工培训与考核 | 提高员工技能水平并建立考核机制 | 加强员工培训、开展技能竞赛和培训活动 | 某纺织厂定期开展员工培训并建立完善的考核机制以提高员工技能水平 | | 环境与安全 | 遵守相关环保法规并确保生产环境安全 | 加强环境与安全监管、确保符合相关法规要求 | 某纺织厂加强环境与安全监管以确保符合相关法规要求的生产环境安全 |

本篇文章介绍了纺织厂管理模板的主要内容以及实际案例分析,通过规范化、系统化的管理手段,可以提高纺织厂的运营效率和管理水平,确保企业的可持续发展,在实际管理中,应结合企业实际情况制定相应的管理措施,并不断优化和完善管理流程。

Articles related to the knowledge points of this article:

The Story of QuanMei Textile Factory