Textile Anti-Mould Treatments:A Comprehensive Guide

: Textile Anti-Mould Treatments: A Comprehensive Guide,Abstract:,This comprehensive guide provides an in-depth understanding of textile anti-mould treatments, covering various methods and their applications. The guide covers the importance of anti-mould treatment for textiles, including its role in preventing mould growth and ensuring product quality. It also discusses the different types of anti-mould treatments available, such as chemical treatments, physical treatments, and biological treatments. The guide provides detailed information on how to choose the right anti-mould treatment method based on the specific requirements of the textile product. Additionally, it includes tips on maintaining effective anti-mould treatments, such as regular cleaning and maintenance procedures. Overall, this guide aims to provide a comprehensive understanding of textile anti-mould treatments, helping readers effectively prevent mould growth and maintain product quality.

Introduction: The textile industry is a crucial sector that produces a wide range of materials, from clothing and furnishings to industrial fabrics. However, these materials are prone to mould growth due to their porous nature and the presence of moisture. Mould can cause damage to the fabric, leading to reduced quality, discoloration, and even health hazards for humans and animals. Therefore, it is essential to implement effective anti-mould treatments on textiles to maintain their durability and prevent mould growth. In this guide, we will discuss the various methods of textile anti-mould treatment and provide an overview of the benefits they offer.

Method 1: Chemical Treatments Chemical treatments involve the use of chemicals that react with the organic matter present in the fabric to inhibit mould growth. These treatments may include pre-treatments or post-treatments depending on the fabric's condition. Pre-treatments involve applying chemicals before the fabric undergoes any further processing, while post-treatments involve applying chemicals after the fabric has been processed.

Benefits of Chemical Treatments: Chemical treatments offer several advantages over other methods of anti-mould treatment. They are effective in preventing mould growth, reducing the risk of damage to the fabric, and extending its lifespan. Additionally, chemical treatments are relatively easy to apply and require minimal maintenance.

However, chemical treatments may also have some drawbacks. They can be harmful to the environment if not used properly, and some chemicals can cause skin irritation or respiratory problems. Therefore, it is essential to follow proper safety guidelines when using these treatments.

Method 2: Enzymatic Treatments Enzymatic treatments involve the use of enzymes that break down the organic matter in the fabric, making it more susceptible to mould growth. These treatments are often used in combination with chemical treatments to enhance their effectiveness.

Benefits of Enzymatic Treatments: Enzymatic treatments offer several advantages over chemical treatments. They are eco-friendly, non-toxic, and do not require harsh chemicals. Additionally, enzymatic treatments can be applied quickly and easily, making them a cost-effective option for businesses that need to treat large volumes of fabric.

However, enzymatic treatments may also have some drawbacks. They may not be as effective as chemical treatments in preventing mould growth, especially in heavily soiled or damaged fabrics. Additionally, the effectiveness of enzymatic treatments may vary depending on the type of fabric and the specific enzyme used.

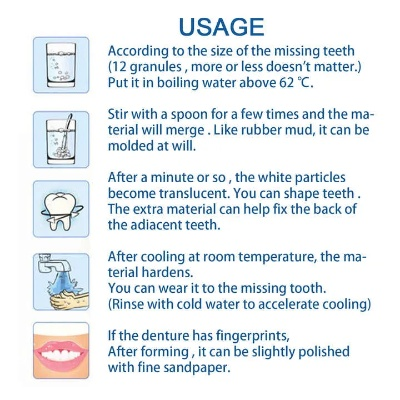

Method 3: Steam Treatments Steam treatments involve the use of high-pressure steam to remove moisture from the fabric. This process helps to eliminate any remaining moisture that could lead to mould growth.

Benefits of Steam Treatments: Steam treatments offer several advantages over other methods of anti-mould treatment. They are effective in removing moisture from the fabric, reducing the risk of mould growth. Additionally, steam treatments can be applied quickly and easily, making them a cost-effective option for businesses that need to treat large volumes of fabric.

However, steam treatments may also have some drawbacks. They can be time-consuming and may not be suitable for all types of fabrics. Additionally, excessive exposure to high-pressure steam can cause damage to the fabric, leading to reduced quality and increased costs.

Case Study: The Benefits of Textile Anti-Mould Treatments In the textile industry, there have been numerous cases where anti-mould treatments have proven to be effective in maintaining the quality and longevity of fabrics. For example, a company that produces clothing used chemical treatments to prevent mould growth on their fabrics. After implementing these treatments, they noticed a significant reduction in stains and discoloration caused by mould. Additionally, they found that their fabrics had a longer lifespan and were less likely to develop damage over time.

Another case study involved a textile manufacturer that used enzymatic treatments to treat their fabrics. They found that these treatments helped to reduce the amount of moisture in the fabric, which in turn prevented mould growth. As a result, they saw an improvement in the overall quality and appearance of their fabrics. Additionally, they found that their customers were satisfied with the improved product and recommended them to others.

Conclusion: Textile anti-mould treatments offer numerous benefits for businesses that produce fabrics. By using chemical, enzymatic, or steam treatments, companies can prevent mould growth and maintain the quality and longevity of their fabrics. However, it is essential to choose the appropriate method based on the fabric's condition and the specific requirements of the business. With proper implementation and maintenance, textile anti-mould treatments can help businesses achieve their goals while minimizing environmental impact.

亲爱的朋友们,今天我们来聊聊纺织品能做防霉处理吗?让我们一起来探讨一下这个话题。

纺织品防霉处理的重要性

纺织品作为日常生活中不可或缺的物品,其质量和使用寿命直接关系到人们的舒适度和健康,霉菌是一种常见的环境问题,它们不仅影响纺织品的外观和质量,还可能引发各种健康问题,对纺织品进行防霉处理显得尤为重要。

纺织品防霉处理的方法

纺织品防霉处理主要涉及到化学处理和物理处理两种方法,化学处理主要是通过添加防霉剂等化学物质来抑制霉菌的生长和繁殖,物理处理则主要是通过改善纺织品的表面结构、提高其抗霉性能等方式来达到防霉的目的。

纺织品能做防霉处理吗?

纺织品确实可以用于防霉处理,某些特殊的纺织面料和服装材料经过特殊的防霉处理后,可以有效防止霉菌的生长和繁殖,延长其使用寿命,现代科技的发展也为纺织品防霉处理提供了更多的可能性,使用纳米技术、生物酶处理等先进技术可以有效地提高纺织品的抗霉性能。

案例分析

让我们通过一个具体的案例来说明纺织品能做防霉处理,假设有一家服装公司,他们生产的一款高档西装面料经过特殊的防霉处理后,不仅外观更加美观,而且经过一段时间的使用后,仍然保持良好的防霉性能,这就是纺织品防霉处理的成功案例。

补充说明

在纺织品防霉处理过程中,我们可以使用多种方法和技术,使用防霉剂可以有效地抑制霉菌的生长和繁殖;使用纳米技术可以改善纺织品的表面结构,提高其抗霉性能;使用生物酶处理则可以有效地提高纺织品的环保性能和生物相容性,还有一些新兴的防霉技术,如紫外线辐射处理、静电吸附处理等,也可以有效地提高纺织品的防霉性能。

纺织品确实可以用于防霉处理,通过添加防霉剂、改善表面结构、使用先进的技术和材料等手段,可以有效防止霉菌的生长和繁殖,延长纺织品的使用寿命,随着科技的发展,纺织品防霉处理也面临着更多的可能性,我们应该重视纺织品防霉处理的重要性,不断提高纺织品的防霉性能和质量。

Articles related to the knowledge points of this article:

How to Peel Textiles for Color

Technological Advances in Industrial Fabrication:A Comprehensive Review

The Design of Textile Industries:A Multidisciplinary Approach

Understanding the Status of Huizhou Quansheng Textiles Listing in Wuxi