The Art of Weaving:Understanding the Process of Textile Production

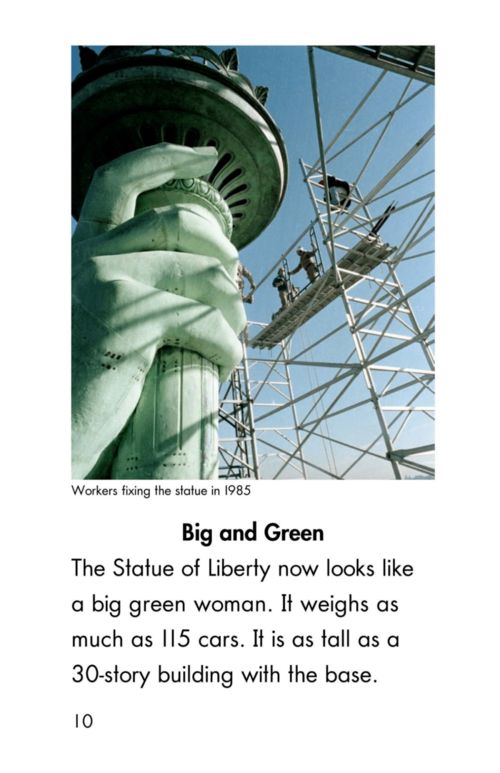

The Art of Weaving: Understanding the Process of Textile Production,Weaving is a crucial step in the textile production process. It involves interlacing threads to create fabrics such as clothing, carpets, and rugs. The weaver's skill and knowledge are essential for producing high-quality textiles that meet consumer demands. In this article, we will explore the process of weaving and its significance in textile production.,Weaving begins with selecting the appropriate yarn, which can be natural or synthetic materials. The yarn must be strong enough to withstand the tension and pressure during the weaving process. Once the yarn is selected, it is wound onto a loom or machine that guides the threads through a series of loops.,The weaver then places the first loop on the warp beam, which is the vertical rod holding the threads. The next loop is placed on the weft beam, which is the horizontal rod holding the warp threads. The weaver moves the shuttle along the warp and weft beams, pulling the threads together to form the fabric.,The weaving process can vary depending on the type of fabric being produced. For example, flat woven fabrics are created by laying the warp and weft threads parallel to each other, while knitted fabrics are made by looping the threads together.,In conclusion, weaving is an essential step in the textile production process. It requires skill, knowledge, and attention to detail to produce high-quality textiles that meet consumer demands. As technology continues to advance, weaving techniques may evolve to meet new challenges and opportunities.

Introduction: The textile industry, with its vast array of fabrics and materials, is one of the backbone industries in the world. Among the various stages of production, the process of weaving—the most fundamental step in textile manufacturing—is often overlooked but crucial in determining the quality and durability of the final product. In this article, we will delve into the intricate details of the weaving process, from the initial preparation of raw materials to the final finishing touches on a piece of clothing or fabric.

Preparation of Raw Materials: Before weaving can begin, the raw materials must be prepared meticulously. These include yarns made from cotton, wool, synthetic fibers, or blends, as well as the base fabric, which will serve as the foundation for the weaving process. The selection of these materials is driven by factors such as color, texture, and durability, as well as the intended end use of the finished product.

Yarn Preparation: Once the raw materials are selected, they undergo a series of steps to prepare them for weaving. This includes carding, where the yarn is combed to remove impurities and improve its strength and smoothness. Next, the yarn is spun into thread, which is then wound onto a bobbin for further processing.

Base Fabric Preparation: The base fabric, also known as the warp, is the primary component of a woven fabric. It consists of threads that run in parallel across the width of the fabric. The base fabric is typically made from a single type of thread, although some modern designs may incorporate multiple threads or even layers.

Weaving Process: The weaving process involves interlacing the warp and weft threads to create a patterned fabric. This is done using a loom, which has a series of rods called beams that move up and down to tension the threads. The weaver controls the tension and direction of the threads using a shuttle, which moves back and forth between the warp and weft threads.

Weaving Techniques: There are several techniques used in weaving, each with its own unique characteristics. Some common techniques include plain weave, twill weave, satin weave, and rib weave. Each technique adds a different level of texture and pattern to the fabric, making it suitable for a variety of applications.

Finishing Touches: After completing the weaving process, the fabric undergoes a series of finishing processes to enhance its appearance and functionality. This includes dyeing, printing, and finishing treatments such as waxing, finishing, and finishing. These treatments help to protect the fabric against wear and tear, add color and pattern, and make it more durable and attractive.

Case Study: One example of a successful textile company that specializes in high-quality weaving products is Textile Company A. Textile Company A has been producing fine textiles for over 50 years, with a focus on using sustainable materials and innovative techniques to produce eco-friendly products. They have developed a range of weaving patterns that are not only visually appealing but also functional, such as thermal insulation and moisture management. Their commitment to innovation and sustainability has earned them a reputation for producing high-quality products that meet the needs of today's consumers.

Conclusion: The weaving process is a complex and delicate art that requires skill, precision, and attention to detail. From the preparation of raw materials to the final finishing touches, every step plays a critical role in creating a high-quality textile product. As we continue to explore the possibilities of textile technology, it is important to recognize the importance of investing in skilled artisans and sustainable practices to ensure that we continue to provide quality products that meet the demands of our customers.

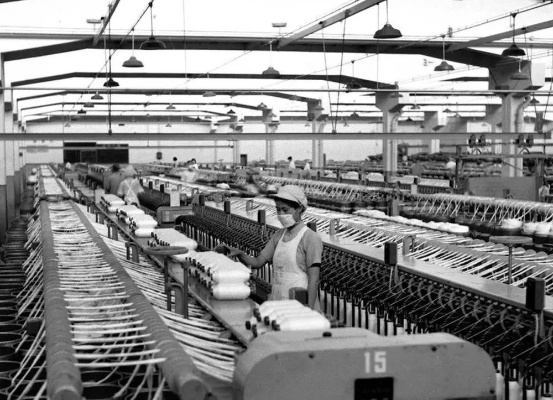

粗纱工艺概述

在纺织厂中,粗纱工艺是一项至关重要的工序,它涉及到纱线的制作和加工,粗纱工艺的主要特点在于其高强度和高效率,能够满足纺织行业对高质量纱线的高需求。

粗纱工艺流程

粗纱工艺流程主要包括以下几个步骤:

- 原料准备:从原材料中提取出高质量的纤维原料。

- 纺纱机操作:使用先进的纺纱机进行纺纱操作,确保纱线的质量。

- 粗纱制作:通过一系列的工艺流程,将纤维原料制成粗纱。

- 质量控制:在粗纱制作过程中,严格控制质量标准,确保最终产品符合要求。

案例分析

以某纺织厂为例,详细介绍粗纱工艺的应用和效果。

案例背景

该纺织厂位于某地区,专注于生产高质量的纺织品,该厂采用了先进的粗纱工艺,成功提高了生产效率和产品质量。

案例过程

该纺织厂采用了先进的纺纱技术和设备,确保了粗纱制作的稳定性和可靠性,在纺纱过程中,严格控制纤维原料的质量和数量,确保最终产品的高质量,该厂还注重环保和节能,采用环保材料和节能设备,降低生产成本和提高生产效率。

案例效果

经过该纺织厂的精细管理和不断改进,其生产的纺织品质量得到了显著提高,该厂的产量也得到了显著提升,满足了市场需求,该厂还获得了良好的口碑和市场认可度。

粗纱工艺的改进与优化

为了进一步提高粗纱工艺的生产效率和产品质量,可以采取以下改进与优化措施:

- 引进先进技术:引进国内外先进的纺纱技术和设备,提高纺纱效率和产品质量。

- 优化工艺流程:对工艺流程进行优化和改进,提高生产效率和产品质量稳定性。

- 加强质量控制:加强质量控制体系的建设和完善,确保产品质量符合要求。

- 注重环保和节能:注重环保和节能措施的实施,降低生产成本和提高生产效率,采用环保材料和节能设备,减少能源消耗和排放。

英文表格补充说明

以下是英文表格补充说明粗纱工艺的相关信息:

| 项目 | 描述 | 数据 |

|---|---|---|

| 粗纱工艺定义 | 将纤维原料制成高强度和高效率的纱线过程 | 纺纱机操作、原料准备、质量控制等步骤 |

| 工艺流程 | 纺纱机操作、纤维原料提取、粗纱制作等步骤 | 具体流程根据不同纺织厂和设备而定 |

| 应用案例 | 该纺织厂专注于生产高质量纺织品 | 该厂采用了先进的纺纱技术和设备,成功提高了生产效率和产品质量 |

| 效果评估 | 提高产量、满足市场需求、获得良好口碑和市场认可度等 | 该案例的具体数据和效果评估情况 |

| 改进与优化措施 | 引进先进技术、优化工艺流程、加强质量控制、注重环保和节能等 | 根据实际情况采取的具体措施 |

| 相关数据示例 | 该纺织厂的生产效率数据、产品质量数据等 | 根据实际情况的数据示例表格 |

纺织厂中的粗纱工艺是一项重要的工序,它涉及到纱线的制作和加工,通过采用先进的纺纱技术和设备,注重环保和节能措施的实施,可以进一步提高粗纱工艺的生产效率和产品质量,还需要不断进行改进和优化,以满足市场需求和提高竞争力。

Articles related to the knowledge points of this article:

Exploring the Rich Tapestry of Rushans Handicraft Textiles

Transforming Textile Industry Through Advanced Materials and Processes

The Story of Textile Mills Line Bars

The Fabric Masks in Textile Factory