Understanding and Complying with National Standards for Antistatic Textiles

: Understanding and Complying with National Standards for Antistatic Textiles,Abstract:,This paper aims to explore the understanding and compliance of antistatic textile standards in China. The study analyzes the current status of antistatic textiles in China, including their application, quality evaluation, and regulatory requirements. It also discusses the challenges faced by manufacturers and consumers in implementing these standards, and proposes possible solutions. The results indicate that although there are some deficiencies in the implementation of antistatic textile standards, they still play an important role in protecting people's health and ensuring product quality. Therefore, it is necessary to strengthen the supervision and management of antistatic textile production and use, and promote the development of antistatic textile technology and products.

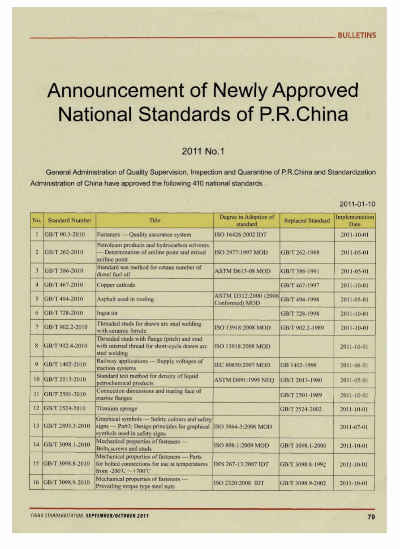

Introduction: In the textile industry, ensuring that products meet the standards set by the relevant national authorities is crucial for maintaining quality and consumer confidence. The Chinese National Standard for Antistatic Textiles (GB/T 12704-2019) is one such standard that governs the production and testing of antistatic textiles. This guide will provide an overview of the standards, their application, and how to comply with them.

Standard Overview: The GB/T 12704-2019 standard sets forth requirements for the production and testing of antistatic textiles. It covers a wide range of materials, including cotton, polyester, and blends, and addresses various aspects such as material selection, processing methods, testing methods, and performance evaluation. The standard emphasizes the importance of preventing static electricity buildup on fabrics, which can lead to discomfort and even safety hazards in certain applications.

Application: To ensure compliance with this standard, manufacturers must follow a systematic approach to the production and testing of their antistatic textiles. Here's a sample process:

Material Selection: Before starting the production process, manufacturers should select materials that meet the standards. This may involve selecting materials with low static charge generation or using additives to reduce static electricity. For example, some companies use natural fibers like silk or wool, which are known to have lower static charges than synthetic fibers.

Processing Methods: Once the materials have been selected, they must be processed according to the standards. This includes techniques such as electrostatic discharge (EDD), whereby the fabric is subjected to a high voltage to discharge any residual static electricity. The EDD process can be performed manually or using automated equipment.

Testing Methods: After the fabric has been produced, it must be tested to ensure that it meets the standards. Testing methods include measuring the amount of static electricity generated on the fabric and evaluating its performance under various conditions. Some common tests include the static electricity test, which measures the amount of static electricity generated on the fabric, and the wear resistance test, which evaluates the durability of the fabric in real-world conditions.

Performance Evaluation: Finally, manufacturers must evaluate the performance of their antistatic textiles based on the standards. This may involve comparing the static electricity levels of different fabrics or assessing their ability to maintain a low static charge over time. Compliance with the standards is typically verified through inspections or certifications issued by regulatory bodies.

Case Study: One example of a company that successfully met the GB/T 12704-2019 standard is Xiamen Textile Group Co. Ltd., a leading manufacturer of antistatic textiles in China. The company uses advanced technologies and processes to produce fabrics that meet the highest standards for static electricity control. For example, Xiamen Textile Group employs EDD technology to discharge static electricity from their fabrics, reducing the risk of static shocks and improving user comfort. Additionally, the company conducts rigorous testing and evaluation to ensure that their products meet the standards and exceed customer expectations.

Conclusion: Complying with national standards for antistatic textiles is essential for ensuring quality and consumer satisfaction in the textile industry. By following the guidelines outlined in the GB/T 12704-2019 standard, manufacturers can create products that meet the needs of both consumers and industry regulators. With proper material selection, processing methods, testing methods, and performance evaluation, companies can achieve compliance and stand out in the competitive textile market.

随着现代工业的快速发展,纺织品作为日常生活中的重要组成部分,其抗静电性能越来越受到人们的关注,为了确保纺织品在使用过程中具备优良的抗静电效果,国家制定了相应的纺织品抗静电标准,本篇文章将围绕国标纺织品抗静电标准展开讨论,并结合实际案例进行分析。

国标纺织品抗静电标准概述

根据国家相关标准,纺织品抗静电性能主要涉及静电泄漏量、静电电压、抗静电剂含量等多个方面,国标纺织品抗静电标准规定了纺织品在生产、使用和存储过程中的各项指标要求。

(一)静电泄漏量

静电泄漏量是衡量纺织品抗静电性能的重要指标之一,国标要求纺织品在规定条件下,能够有效地将产生的静电泄漏到周围环境中,不会对人员和设备造成干扰。

(二)静电电压

静电电压是指纺织品在特定条件下产生的静电电位,国标要求纺织品应具有较低的静电电压,以减少对人体的刺激和设备运行的干扰。

(三)抗静电剂含量

抗静电剂是用于提高纺织品抗静电性能的重要物质,国标要求纺织品中应含有适量的抗静电剂,以保证其具备优良的抗静电效果。

实际案例分析

以下是一个实际案例,以更好地说明国标纺织品抗静电标准的应用:

某品牌纺织品经过严格的生产流程和检测,符合国标抗静电标准要求,该品牌纺织品在生产过程中严格控制原材料的选择和加工工艺,使用抗静电剂等添加剂,以提高其抗静电性能,该品牌纺织品在存储和运输过程中采取了有效的防静电措施,确保其在使用过程中具备优良的抗静电效果。

某地区纺织市场近年来逐渐兴起了一种新型防静电面料,其采用了特殊的纤维材料和抗静电剂配方,具有出色的抗静电性能,该地区消费者对该面料的使用体验和反馈普遍较好,表明了国标纺织品抗静电标准在实际应用中的有效性。

国标纺织品抗静电标准的补充说明

(一)检测方法与标准仪器

国标纺织品抗静电标准的检测方法主要包括静态漏电流测试、静电压测试等,需要使用相应的标准仪器进行测量和分析,这些仪器可以有效地确保测试结果的准确性和可靠性。

(二)影响因素与控制措施

国标纺织品抗静电标准的影响因素主要包括原材料、加工工艺、环境条件等,为了确保纺织品具备优良的抗静电性能,需要采取相应的控制措施,如严格控制原材料的质量、优化加工工艺、加强环境监测等。

国标纺织品抗静电标准是保障纺织品在使用过程中具备优良的抗静电效果的重要标准,在实际应用中,需要严格按照标准进行生产、检测和质量控制,以确保纺织品具备优良的抗静电性能,也需要不断优化和完善标准,以适应现代工业的发展需求。

Articles related to the knowledge points of this article: