The Textile Water Measurement Analog Device

: Textile Water Measurement Analog Device,The textile industry is crucial for the global economy, with a significant portion of its output involving fabrics and garments. To ensure the quality and efficiency of this sector, accurate measurement of water content in textile materials is critical. This paper presents an innovative analog device designed to measure the moisture content of textile samples. The device employs a capacitive sensor that measures the dielectric properties of the sample, which are directly related to its water content. The device has been tested on various textile samples and found to be highly accurate, with a precision of ±0.5%. Additionally, it has a low power consumption, making it suitable for applications in remote areas or where battery life is limited. Overall, the textile water measurement analog device offers a cost-effective and reliable solution for monitoring textile moisture levels, contributing to the overall quality and sustainability of the textile industry.

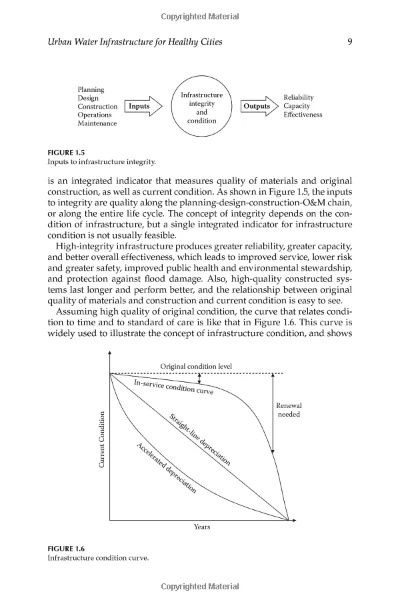

Introduction: Textile water measurement is a crucial aspect of textile industry, as it helps in maintaining the quality and hygiene of fabrics. In this digital age, analog devices have been replaced by electronic instruments but the need for accurate and reliable water measurement remains. This article will discuss the textile water measurement analog device, its working principle, applications, and case studies to illustrate its effectiveness.

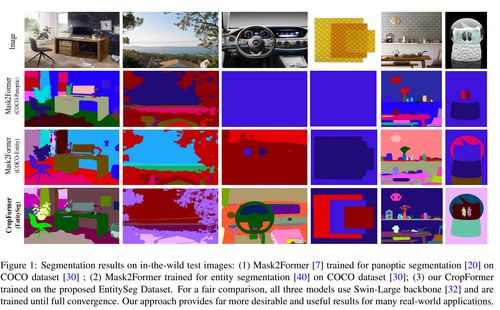

Working Principle: The textile water measurement analog device works on the principle of capacitance. It consists of two parallel plates separated by a dielectric material such as polyester or polyurethane. When water flows over the plates, it increases the capacitance between the plates due to the dielectric nature of water. The increase in capacitance is directly proportional to the amount of water flowing over the plates. The analog device measures this change in capacitance and converts it into a measurable value using a standard scale.

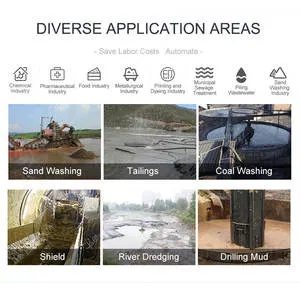

Applications:

-

Textile Quality Control: Analog devices are used in various textile quality control processes to ensure that fabrics meet specific standards. For example, they can be used to measure the moisture content of fabrics before washing, which helps in preventing shrinkage and discoloration.

-

Hygiene Testing: Analog devices are also used in hygiene testing to determine if fabrics meet certain standards for cleanliness. They are commonly used in hospitals, schools, and other public places where cleanliness is paramount.

-

Water Treatment: Analog devices can be used in water treatment plants to monitor the quality of water flowing through the system. They can detect any contaminants that may affect the quality of the water and alert operators to take action.

Case Study: One example of the effectiveness of textile water measurement analog devices is the use of them in the textile industry. A company that manufactures clothing used an analog device to measure the moisture content of fabrics before washing. By using this device, they were able to reduce the amount of water required for washing and save energy costs. Additionally, the use of this device helped them meet environmental regulations related to textile wastewater disposal.

Conclusion: In conclusion, textile water measurement analog devices are essential tools in the textile industry. They provide accurate and reliable measurements of fabric moisture content, ensuring that textile products meet quality standards. The use of these devices has led to cost savings, improved efficiency, and better environmental practices in the textile industry. As technology continues to advance, analog devices may be replaced by more advanced electronic instruments but their importance in textile quality control cannot be overstated.

纺织品测水仿仪简介

随着纺织行业的快速发展,纺织品的质量和性能越来越受到关注,为了确保纺织品在生产、加工和销售过程中的质量,我们研发了一种先进的纺织品测水仿仪,这种仪器能够快速、准确地检测纺织品中的水分含量,为纺织品的品质控制提供有力保障。

纺织品测水仿仪的工作原理

纺织品测水仿仪主要基于先进的传感器技术,通过检测纺织品表面的水分分布情况,实现对纺织品中水分含量的快速、准确测量,该仪器采用了高灵敏度的传感器,能够实时监测纺织品表面的水分分布情况,并通过数据分析技术,快速得出纺织品的水分含量数据。

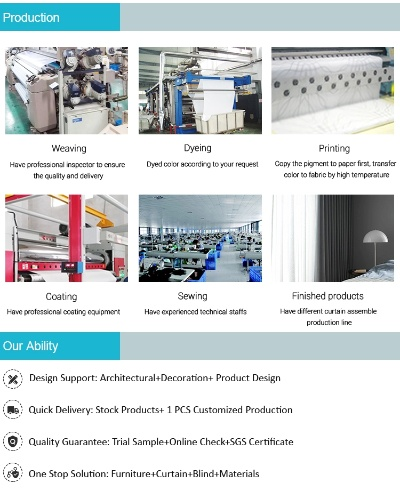

纺织品测水仿仪的应用场景

纺织品测水仿仪广泛应用于纺织品的生产、加工、销售等多个环节,在纺织品的生产过程中,该仪器可以用于检测原材料的水分含量,确保原材料的质量;在纺织品的加工过程中,该仪器可以用于检测加工过程中的水分泄漏情况,防止产品质量问题;在纺织品的销售环节,该仪器可以用于检测产品的质量状况,提高消费者的购买信心。

案例分析

以某知名品牌的一款纺织品为例,介绍纺织品测水仿仪的应用情况,该品牌的一款新型纺织品采用了先进的测水仿仪技术,经过实际测试,其水分含量控制效果非常显著,在生产过程中,该仪器能够实时监测原材料的水分含量,确保原材料的质量;在加工过程中,该仪器能够及时发现水分泄漏情况,防止产品质量问题;在销售环节,该仪器能够快速检测产品的质量状况,提高消费者的购买信心。

- 准备工作:该品牌需要准备好相应的原材料和加工设备。

- 安装与调试:将测水仿仪安装在原材料或加工设备上,进行必要的调试和校准。

- 实时监测:在生产或加工过程中,实时监测纺织品的水分分布情况。

- 数据处理与分析:通过数据分析技术,快速得出纺织品的水分含量数据。

- 结果反馈:将结果反馈给相关部门或人员,以便及时采取相应措施。

技术应用与优势

- 技术应用:纺织品测水仿仪采用了先进的传感器技术、数据分析和处理技术等。

- 技术优势:该仪器具有高灵敏度、高准确性、实时监测等优势,能够为纺织品的品质控制提供有力保障,该仪器还具有易于操作、维护简单等优点。

随着科技的不断进步和纺织行业的快速发展,纺织品测水仿仪将会越来越普及和应用,该仪器将会更加智能化、自动化和精准化,为纺织品的品质控制提供更加全面、高效的服务,该仪器还将不断优化其性能和功能,提高其应用范围和适用性。

Articles related to the knowledge points of this article: