The Fabrication Process:A Comprehensive Guide to Manufacturing Textile Goods

This comprehensive guide provides a detailed overview of the fabrication process for manufacturing textile goods. The guide covers topics such as materials selection, design and pattern preparation, weaving and knitting techniques, finishing processes, and quality control measures. It also includes tips on how to optimize production efficiency and reduce waste. By following this guide, readers can gain a deep understanding of the textile industry and become proficient in their own fabrication processes.

Introduction: In the textile industry, fabrication is the process of transforming raw materials into finished products. It involves a series of steps from sourcing materials to producing high-quality garments or other textile goods. In this guide, we will explore the key stages of the fabrication process and provide insights into how it works.

Step 1: Material Sources The first step in the fabrication process is sourcing raw materials. This includes selecting the right fabrics, yarns, and other components that will be used to create textile goods. The selection process involves evaluating different suppliers based on their quality, cost, and availability.

Example: A textile company may source polyester fabric for its shirts, which is then dyed with various colors before being cut and sewn together to form the garment.

Step 2: Production Planning Once material sources are secured, production planning becomes essential. This involves determining the quantity of goods needed, setting up production schedules, and assigning tasks to different departments.

Example: A textile company may plan to produce 10,000 T-shirts per month, with each T-shirt requiring 5 meters of fabric and 30 pieces of buttons. The company will need to coordinate with its suppliers, designers, and sewing machines to ensure that all requirements are met.

Step 3: Design and Pattern Making Designing and pattern making are crucial steps in the fabrication process. These involve creating designs for garments, choosing patterns, and preparing them for printing or embroidery.

Example: A textile company may design a new line of women's dresses using a digital design software. Once the design is approved, the company will print the pattern onto a transfer paper and then transfer it to the fabric.

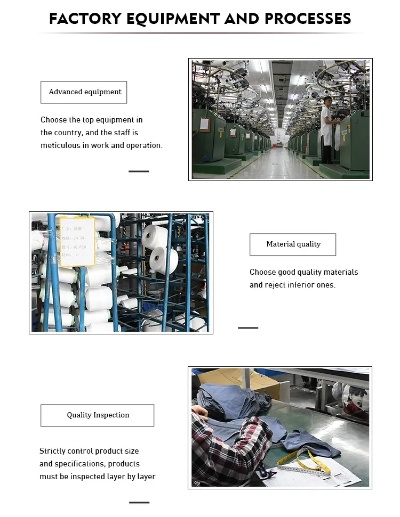

Step 4: Cutting and Sewing Cutting and sewing are the final steps in the fabrication process. These involve cutting the fabric into individual pieces, stitching them together, and finishing them according to the manufacturer's specifications.

Example: After cutting the fabric, the company will sew the pieces together using a sewing machine. The company may also add embellishments such as buttons, zippers, or linings to enhance the aesthetic appeal of the garment.

Step 5: Quality Control Quality control is an important aspect of the fabrication process. This involves testing the finished goods for defects such as loose threads, uneven seams, or missing buttons.

Example: A textile company may conduct spot checks on its garments to identify any issues with the stitching or color matching. If any defects are found, the company will address them immediately and ensure that the same problem does not occur in subsequent batches.

Conclusion: The fabrication process is a complex and multifaceted task that requires careful planning, execution, and quality control. By following the steps outlined above, textile companies can produce high-quality garments that meet consumer expectations and stay competitive in today's market.

在纺织品行业中,代工流程是一个复杂而关键的环节,本篇将详细介绍纺织品代工的基本流程,并结合实际案例进行说明。

纺织品代工流程概述

材料采购

材料采购是代工流程的起点,涉及从原材料供应商处采购各种纺织材料。

初步加工

在材料采购后,需要进行初步加工,如裁剪、缝纫等。

品质检验

在加工过程中,品质检验是确保产品质量的重要环节,通过严格的质量检验,确保产品符合相关标准和客户要求。

成品检验

成品检验是确保最终产品质量的关键环节,通过严格的质量检测和评估,确保产品符合最终客户的要求。

具体流程说明

以下是纺织品代工的具体流程:

材料采购阶段:

材料采购阶段包括选择合适的原材料供应商、签订采购合同等步骤,在具体操作中,需要关注原材料的质量、价格、交货时间等因素,还需要对供应商进行评估和选择,以确保采购到高质量的原材料。

某纺织品公司选择了一家知名的面料供应商进行采购,经过多轮谈判和评估,最终签订了采购合同,在材料采购阶段,公司需要关注原材料的质量、价格、交货时间等因素,以确保采购到符合要求的原材料。

初步加工阶段:

初步加工阶段包括裁剪、缝纫等工序,在具体操作中,需要根据客户的要求和产品特点,选择合适的工艺和设备进行加工,还需要对加工过程中的质量进行严格控制,以确保最终产品的质量和性能符合要求。

某纺织品公司在初步加工阶段使用了先进的缝纫设备和技术,确保了产品的质量和性能符合要求,公司还对加工过程中的质量进行了严格的把关和控制,确保了产品的安全性和可靠性。

品质检验阶段:

品质检验阶段是对加工产品进行质量检测和评估的重要环节,在具体操作中,需要制定严格的质量检测标准和流程,以确保产品质量符合相关标准和客户要求,还需要对检测结果进行认真分析和处理,以便及时发现和解决问题。

某纺织品公司在品质检验阶段采用了先进的检测设备和仪器,对产品进行了全面的质量检测和评估,公司还建立了完善的检测标准和流程,确保了产品质量符合相关标准和客户要求,在检测过程中,公司还及时发现了多个质量问题并进行了及时处理和改进。

案例说明

以一家知名纺织品公司为例,其纺织品代工流程如下:

-

材料采购阶段:该公司选择了一家专业的面料供应商进行采购,经过多轮谈判和评估,最终签订了长期合作协议,在材料采购过程中,该公司关注了原材料的质量、价格、交货时间等因素,以确保采购到高质量的原材料,该公司还建立了完善的供应商评估和选择机制,以确保供应商的稳定性和可靠性。

-

初步加工阶段:该公司采用了先进的缝纫设备和技术进行初步加工,确保了产品的质量和性能符合要求,该公司还建立了严格的品质检验标准和流程,对加工过程中的质量进行了严格控制,在品质检验过程中,该公司及时发现并解决了多个质量问题,确保了产品的质量和性能得到了有效保障。

纺织品代工流程是一个复杂而关键的环节,需要关注材料采购、初步加工、品质检验等多个环节,在实际操作中,需要选择合适的原材料供应商、制定严格的质量检测标准和流程、建立完善的供应商评估和选择机制等,还需要注重产品质量和性能的控制和改进,以确保最终产品的质量和性能符合要求。

Articles related to the knowledge points of this article:

The Top Brands in Textile Home Textiles

The Strange Tale of the Textiles Towers Ghostly Residence