The Fabrication of Antimicrobial Textiles and Their Classification

Antimicrobial textiles have become increasingly popular in recent years due to their potential applications in healthcare, sportswear, and other fields. These fabrics are designed to inhibit the growth of harmful microorganisms such as bacteria and fungi, thereby preventing infections and promoting a healthier lifestyle. In this paper, we provide an overview of the fabrication techniques used to produce antimicrobial textiles, including physical methods like electrostatic spinning and chemical treatments such as graft polymerization and ion exchange. We also discuss the classification of these textiles based on their mode of action, including contact and non-contact methods. Finally, we highlight the challenges and opportunities associated with the development of antimicrobial textiles, including the need for sustainable and eco-friendly materials and the potential risks associated with their use.

Introduction: In the current era, where hygiene and safety are paramount concerns, textiles have become a primary target for developing antimicrobial properties. This is because microbes can cause infections that affect both human health and the environment. Textiles with antimicrobial properties are increasingly being used in various applications such as healthcare, sportswear, and home furnishings. In this article, we will explore the methods of fabricating antimicrobial textiles and their classification based on different mechanisms of action.

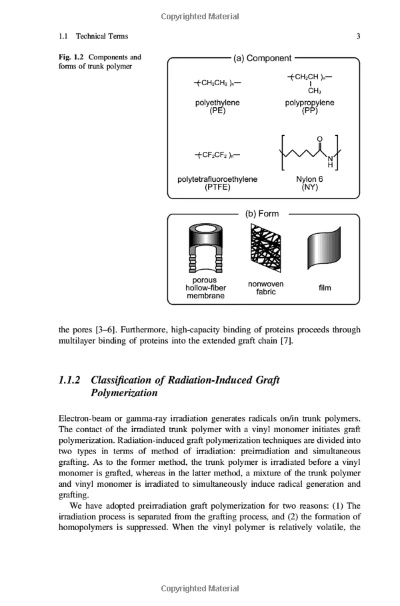

Methodology: There are several techniques employed in the production of antimicrobial textiles. These include physical treatments, chemical treatments, and biological treatments. Physical treatments involve using ultraviolet light or heat to kill bacteria on the surface of the fabric. Chemical treatments involve incorporating chemicals into the fibers or coating them with antimicrobial agents. Biological treatments involve using natural materials like silver nanoparticles or plant extracts to inhibit bacterial growth.

Classification: Antimicrobial textiles can be classified based on their mechanism of action. Here are some common types:

-

Chlorine-based: This type of antimicrobial treatment involves the use of chlorine gas or salts to kill bacteria. It is widely used in swimming pool liners and other water-contact products.

-

Silver-based: Silver nanoparticles are added to the fibers of the fabric to create an antimicrobial layer. This method is effective against a wide range of bacteria and fungi.

-

Zinc-based: Zinc oxide is added to the fibers to create an antimicrobial layer. It is effective against bacteria and fungi but may not be as effective against viruses.

-

Natural-based: Natural antimicrobial agents like tea tree oil, lavender oil, and neem oil are extracted from plants and added to the fabric. They are effective against a wide range of bacteria and fungi but may not be as effective against viruses.

Case Study: One example of a successful antimicrobial textile is the "Braided Nylon" developed by DuPont. This product uses a combination of zinc oxide and silver nanoparticles to create an antimicrobial layer on the fabric. The result is a textile that is effective against a wide range of bacteria and fungi while also being soft and comfortable to wear.

Conclusion: Textiles with antimicrobial properties are essential in today's world. They help to prevent the spread of infections and ensure a safer environment for humans and the planet. By understanding the different methods of fabricating antimicrobial textiles and their classification, we can make informed decisions when selecting products that meet our needs.

纺织品抗菌方法概述

随着人们对健康和生活品质的追求不断提高,抗菌纺织品的需求日益增长,抗菌纺织品是一种能够有效抑制细菌生长和繁殖的材料,具有广泛的应用前景,本文将详细介绍纺织品抗菌的方法和分类。

抗菌纺织品的主要方法

物理抗菌方法:

(1)表面处理:通过在纺织品表面添加抗菌涂层或使用抗菌剂,达到抗菌效果,使用银离子、锌离子等抗菌剂对纺织品进行表面处理,可以有效抑制细菌生长。

(2)织物结构设计:通过改变织物的纤维排列、孔隙率等织物结构,提高织物的抗菌性能,使用抗菌纤维、抗菌纱线等特殊纤维材料,可以显著提高纺织品的抗菌效果。

化学抗菌方法:

(1)合成抗菌剂:通过合成具有抗菌性能的化学物质,添加到纺织品中,达到抗菌效果,常见的合成抗菌剂包括季铵盐类、重金属离子类等。

(2)生物酶抗菌剂:利用生物酶的特性,在纺织品表面形成一层生物膜,有效抑制细菌生长,生物酶抗菌剂具有环保、无残留等特点,适用于各种材质的纺织品。

纺织品抗菌的分类

根据不同的分类标准,纺织品抗菌可以分为多种类型,以下是几种常见的分类方式:

按用途分类:

(1)医用纺织品:用于医疗场所的衣物、床单等。

(2)日常消费品纺织品:家居用品、运动服装等。

按材料分类:

(1)天然纤维纺织品:如棉、麻、丝等天然纤维材料制成的纺织品。

(2)合成纤维纺织品:如聚酯纤维、聚酰胺纤维等合成纤维材料制成的纺织品。

按抗菌性能分类:

(1)高抗菌性能纺织品:具有出色的抗菌效果,适用于医疗场所和需要高抗菌性能的纺织品。

(2)中低抗菌性能纺织品:适用于日常消费品和一般用途的纺织品。

案例说明

以某品牌的高抗菌性能纺织品为例,说明其具体应用和效果,该品牌的高抗菌性能纺织品采用了先进的物理和化学抗菌技术,具有出色的抗菌效果和环保特性,该产品适用于医疗场所和日常消费品领域,可以有效抑制细菌生长和繁殖,提高穿着者的健康水平,该产品还具有较好的透气性和舒适性,适合各种材质的纺织品使用。

纺织品抗菌是现代生活中越来越重要的话题,随着人们对健康和生活品质的追求不断提高,对纺织品抗菌的要求也越来越高,我们需要不断探索和创新纺织品抗菌的方法和手段,以满足人们的需求,我们也需要关注纺织品的环保性和可持续性,推动纺织品的可持续发展。

Articles related to the knowledge points of this article: