The Role of Dryers in Textiles and Their Impact on Quality and Safety

Dryers are crucial in the textile industry as they play a pivotal role in the quality and safety of the final product. They ensure that the fabric is dried thoroughly, preventing moisture-related issues such as mildew growth and shrinkage. The drying process also ensures that the fabric maintains its shape and color, making it more durable and resistant to wear and tear.,The use of dryers has a significant impact on the quality of the textiles produced. They help to remove excess moisture from the fabric, which can cause discoloration or damage to the material. This ensures that the fabric looks its best and lasts longer.,Moreover, the proper use of dryers contributes to the overall safety of the workers involved in the textile industry. Drying equipment should be used correctly to avoid accidents caused by overheating or improper handling of the fabric.,In conclusion, dryers play a vital role in the textile industry, ensuring the quality and safety of the final product. Their proper use helps to produce high-quality textiles that meet the standards set by industry regulations.

Introduction: In the textile industry, the use of dryers is an essential step in the production process. These machines play a crucial role in removing excess moisture from raw materials and finished products, ensuring that they meet quality standards and are safe for consumers. In this article, we will explore the different types of dryers used in textiles, their benefits, and some common challenges faced by manufacturers. We will also provide an overview of some successful cases where dryers have significantly improved product quality and safety.

Types of Dryers in Textiles:

-

Rotary Driers: These are the most common type of dryer used in the textile industry. They consist of a rotating drum with heating elements that circulate hot air to dry the fabric. Rotary dryers are efficient and can quickly remove moisture from large volumes of fabric.

-

Vacuum Driers: These dryers use a vacuum system to draw out moisture from the fabric. They are particularly useful for drying delicate or high-value textiles that may be damaged by heat.

-

Convection Driers: These dryers use hot air to circulate through the fabric, causing it to dry more evenly. They are ideal for drying bulky or heavy materials that may not fit well into rotary dryers.

Benefits of Dryers in Textiles:

-

Quality Improvement: Dryers help to remove excess moisture from fabric, preventing shrinkage, wrinkles, and other quality issues. This ensures that finished products meet consumer expectations and are durable.

-

Product Safety: By controlling the level of moisture in fabrics, dryers reduce the risk of mold growth and other health hazards associated with damp materials.

-

Efficiency: Dryers are highly efficient at converting energy into heat, which means that manufacturers can save money on electricity costs. Additionally, they can process larger volumes of fabric per hour than traditional methods.

Challenges Faced by Manufacturers:

-

Energy Consumption: Dryers require a significant amount of energy to operate, which can be expensive for manufacturers. However, advancements in technology have led to more energy-efficient dryers that can reduce costs while still maintaining high efficiency.

-

Environmental Impact: Manufacturers must consider the environmental impact of their dryers. For example, using less energy-intensive drying methods or recycling spent water can help minimize waste and pollution.

Successful Case Studies:

-

Nike's Use of Rotary Dryers: Nike has been using rotary dryers to dry its sportswear fabrics since the 1970s. These dryers have helped Nike produce high-quality, durable sportswear that meets consumer expectations.

-

Bang & Olufsen's Use of Convection Dryers: Bang & Olufsen uses convection dryers to dry its luxury electronics components. These dryers allow the company to control the temperature and humidity levels of the fabrics, ensuring that they remain free from moisture and bacteria.

Conclusion: Dryers play a crucial role in the textile industry, improving product quality and safety while reducing energy consumption and environmental impact. As technology continues to advance, we can expect to see even more innovative and energy-efficient dryers that will continue to benefit both manufacturers and consumers.

大家好,今天我们将探讨纺织品中常见的干燥剂及其英文表达,干燥剂在纺织品中扮演着关键角色,特别是在需要保持衣物干燥和防潮的环境中,本文将通过英文案例和表格,详细介绍纺织品干燥剂的相关知识。

纺织品中的干燥剂类型

- 硅胶干燥剂:硅胶干燥剂是一种常见的干燥剂,具有吸湿、防潮的特性,它广泛应用于各种纺织品中,如床单、毛巾、衣物等。

- 活性炭干燥剂:活性炭干燥剂具有吸附能力强、吸附效率高的特点,常用于防潮和除异味,它在纺织品中的应用也日益广泛。

- 氧化钙干燥剂:氧化钙干燥剂是一种无机干燥剂,具有快速吸湿和防潮的特性,它适用于需要快速干燥的纺织品。

干燥剂英文表达

- 硅胶干燥剂:Silica gel dryer

- 活性炭干燥剂:Activated carbon dryer

- 氧化钙干燥剂:Calcium oxide dryer

案例说明

硅胶干燥剂的应用案例

假设我们有一个纺织品制造商,他们需要一款高效的干燥剂来保持衣物干燥和防潮,他们选择了硅胶干燥剂作为首选,以下是硅胶干燥剂的应用案例:

某品牌床单的干燥效果展示

描述:该品牌床单采用了硅胶干燥剂,经过一段时间的使用后,其表面看起来仍然保持干燥,没有出现潮湿或霉变的现象,消费者对该产品的满意度非常高。

硅胶干燥剂在纺织品中的应用广泛,能够有效保持衣物干燥和防潮。

干燥剂英文案例说明

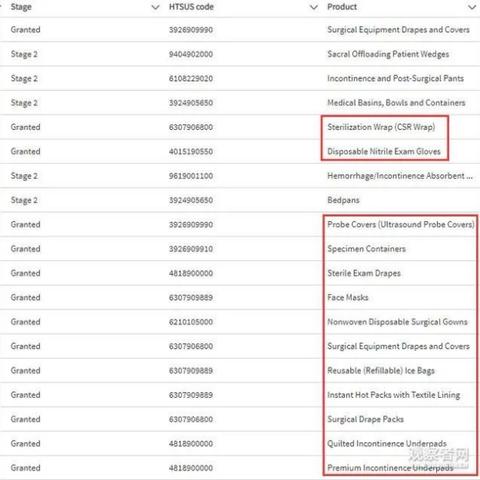

在英文中,我们可以使用表格来详细说明各种干燥剂的应用案例和英文表达,以下是表格示例:

| 干燥剂类型 | 应用案例 | 英文表达 |

|---|---|---|

| 硅胶干燥剂 | 纺织品干燥剂 | Silica gel dryer |

| 活性炭干燥剂 | 防潮材料 | Activated carbon dryer |

| 氧化钙干燥剂 | 快速吸湿材料 | Calcium oxide dryer |

干燥剂的选购与使用注意事项

- 选购干燥剂时需要注意以下几点:选择正规品牌、关注吸湿防潮性能、注意保存条件等。

- 使用干燥剂时需要注意以下几点:避免潮湿环境、定期更换、避免与其他物品混合使用等。

纺织品中的干燥剂是确保衣物和纺织品保持干燥和防潮的关键因素,在选择和使用干燥剂时,我们需要关注产品的性能、安全性以及保存条件等因素,通过本文的介绍,我们希望能够帮助大家更好地了解纺织品中的干燥剂及其英文表达。

Articles related to the knowledge points of this article:

A Comprehensive Overview of Textile Goods Tariff Structures and Case Studies

Empowering Textiles:Exploring the Fabric of Success in Cottons Heartland

Global Trade in Fashion Textiles:An Overview of Key Markets and Industries

Exploring the Art of Romance in Textiles

The Art of Textile Labels and Their Incredible Benefits for Customers