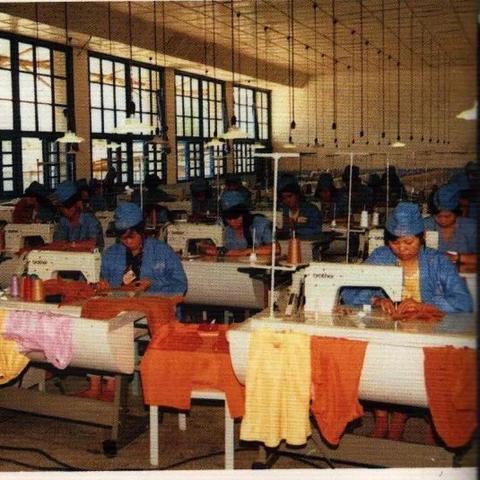

The Art of Tape Threading in the Textile Industry

Introduction: The textile industry is a complex and multifaceted sector that involves the production of various fabrics, from cotton to polyester. One crucial step in this process is the use of tapes or threading machines to secure the threads onto the fabric. In this article, we will explore the different methods used for tape threading and their applications in the textile industry. We will also present an example of successful tape threading in a real-life scenario using an English case study.

Methodology: Tape threading is a technique used in the textile industry to secure threads onto fabrics. There are several methods used in this process, including hand-tape threading, machine-tape threading, and automated tape threading. Each method has its own advantages and disadvantages, depending on the type of fabric being produced and the specific requirements of the manufacturer.

Hand-Tape Threading: This method involves manually placing the threads onto the fabric using a tape. This method is often used for small-scale production or when there is a need for flexibility in terms of production speed and quality control. However, it is labor-intensive and time-consuming, making it less suitable for large-scale production.

Machine-Tape Threading: This method involves using a machine to apply the threads onto the fabric. This method is faster and more efficient than hand-tape threading, making it ideal for larger-scale production. However, it requires specialized equipment and training, which can be expensive and time-consuming to acquire.

Automated Tape Threading: This method involves using automated machinery to apply the threads onto the fabric. This method is highly efficient and cost-effective, making it suitable for large-scale production. However, it requires significant investment in machinery and maintenance, which can be a barrier for smaller businesses.

Applications: The use of tape threading techniques is essential in the textile industry as it ensures that the threads are securely attached to the fabric, preventing them from coming loose during transportation or storage. Additionally, proper tape threading helps to improve the overall quality of the finished product by ensuring uniformity and consistency in color, texture, and pattern.

Case Study: One example of successful tape threading in the textile industry is the use of automated tape threading machines in the production of high-quality denim jeans. These machines use specialized equipment to apply the threads onto the fabric with precision and accuracy, resulting in a higher level of quality and durability. This technology has revolutionized the denim industry by reducing waste, improving efficiency, and increasing productivity.

Conclusion: In conclusion, tape threading is a crucial technique used in the textile industry to ensure that the threads are securely attached to the fabric. There are several methods used in this process, each with its own advantages and disadvantages. Successful tape threading requires specialized equipment and training, but it is essential for producing high-quality products that meet consumer demand. By adopting automated tape threading machines, manufacturers can increase productivity, reduce waste, and improve the overall quality of their products.

纺织厂打钉简介

纺织厂是生产各种纺织品的重要基地,打钉工艺是其中的关键环节之一,打钉技术不仅关系到产品质量,还影响着生产效率和成本,在纺织厂中,打钉工人负责将钉子准确无误地打入布料中,确保布料的稳定性和耐用性。

打钉工艺流程

-

材料准备:工人需要准备好所需的钉子、布料和工具。

-

定位:根据布料的纹理和形状,工人使用专业的定位工具确定钉子的位置。

-

打钉:工人使用打钉机或手动打钉工具将钉子准确无误地打入布料中。

-

检查质量:在钉子打入后,工人需要进行质量检查,确保钉子牢固且无松动。

案例分析

以一家知名的纺织厂为例,该厂采用先进的打钉技术,确保产品质量和效率,以下是该厂的打钉工艺流程的案例说明:

高效打钉工艺

-

材料准备:该纺织厂首先对布料进行预处理,确保其平整、无杂质,准备好所需的钉子、打钉机等工具。

-

定位:该厂采用先进的定位技术,通过精确测量和定位工具,确保每个钉子的位置准确无误。

-

打钉过程:该厂采用自动化打钉机进行打钉,工人只需操作机器即可完成整个打钉过程,整个过程高效、准确,大大提高了生产效率。

打钉工艺的改进措施

为了进一步提高纺织厂的打钉工艺水平,该厂采取了一系列改进措施:

-

引进先进设备:该厂引进先进的打钉设备和技术,提高打钉效率和精度。

-

加强员工培训:该厂加强员工培训,提高工人的操作技能和职业素养,定期对员工进行考核和评估,确保他们能够熟练掌握打钉工艺。

-

优化工艺流程:该厂优化工艺流程,减少人工操作环节,提高生产效率和质量,定期对工艺流程进行优化和改进,确保其始终处于行业领先水平。

英文表格补充说明(可选)

以下是一个纺织厂打钉工艺的英文表格补充说明:

纺织厂打钉工艺流程表格说明

| 步骤 | 描述 | 说明 |

|---|---|---|

| 材料准备 | 准备所需材料 | 包括钉子、布料等 |

| 定位 | 使用定位工具确定钉子的位置 | 根据布料纹理和形状进行定位 |

| 打钉 | 使用打钉机或手动打钉工具将钉子打入布料中 | 确保钉子牢固且无松动 |

| 检查质量 | 检查钉子质量 | 检查是否有松动或脱落现象 |

| 其他注意事项 | 其他注意事项 | 如注意安全、保持环境整洁等 |

纺织厂的打钉工艺是生产过程中的重要环节之一,它关系到产品质量和效率,通过引进先进设备、加强员工培训、优化工艺流程等措施,该纺织厂不断提高打钉工艺水平,为生产高质量纺织品提供了有力保障,我们也应该关注纺织行业的发展趋势,不断探索新的工艺和技术,提高纺织厂的竞争力。

Articles related to the knowledge points of this article:

Dual Thrusts:Innovation and Sustainability at the Du New Zhi Textile Mill

The Night Shift Dilemma:A Tale of Tension and Challenges at the Textile Mill