Textile Antiviral Management Measures

: Textile Antiviral Management Measures,In recent years, the outbreak of infectious diseases has become a major public health concern, especially in textile industries. The use of antiviral agents in textile production can effectively prevent the spread of viruses and protect workers' health. This paper discusses the application of antiviral agents in textile production, including their classification, properties, and methods of use. It also analyzes the effectiveness of antiviral measures in preventing virus transmission in textile production and provides suggestions for further research and development. In conclusion, the adoption of antiviral management measures in textile production is crucial for protecting workers' health and ensuring the safety of the entire industry.

Introduction: In the current global health landscape, the threat of infectious diseases has never been more pressing. Among the myriad viruses that pose a challenge to human health, textile materials have been identified as potential vectors for the spread of viruses such as influenza and COVID-19. This is why it is essential to implement robust antiviral management measures within the textile industry to ensure consumer safety and protect public health. In this article, we will discuss the importance of antiviral management in textiles, the various methods available for controlling virus transmission, and how these measures can be effectively implemented in different stages of the production process.

Antiviral Management in Textiles: The Significance of Prevention The prevention of viral transmission in textiles is crucial not only for protecting workers but also for maintaining public health. By implementing antiviral management measures, textile companies can reduce the risk of virus outbreaks by minimizing the exposure of fabrics to potentially contaminated materials or surfaces. This can include using disinfectants, sterilizing equipment, and ensuring proper ventilation during the production process.

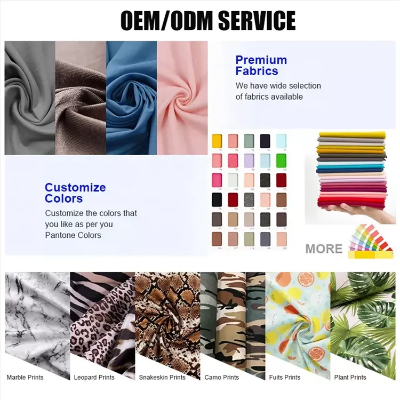

Methods of Antiviral Management in Textiles There are several methods available for controlling virus transmission in textiles, each with its own advantages and limitations. Here are some of the most common approaches:

-

Chemical Disinfection: Chemical disinfection involves the use of chemicals to kill or inhibit the growth of viruses on textiles. Some commonly used chemicals include quaternary ammonium compounds, glutaraldehyde, and sodium hypochlorite. These chemicals can be applied through spraying, dipping, or immersion methods. However, chemical disinfection may leave residues on fabrics that can affect their appearance or performance.

-

UV Light Treatment: UV light treatment uses ultraviolet radiation to kill or inactivate viruses on textiles. This method is effective in reducing the number of viruses present on fabrics but may not be suitable for all types of textiles due to their sensitivity to UV light. Additionally, UV light treatment may require specialized equipment and expertise.

-

Heat Treatment: Heat treatment involves exposing textiles to high temperatures to inactivate viruses. This method is effective in killing or inactivating viruses but may result in changes to the fabric's structure and color. Heat treatment may also require specialized equipment and expertise.

-

Air Filtration: Air filtration involves using filters to remove airborne particles and viruses from the textile production environment. This method is effective in reducing the risk of virus transmission but may not be sufficient if the source of contamination is located outside the production area.

Implementing Antiviral Management Measures To implement antiviral management measures effectively, textile companies must follow a systematic approach that considers the following factors:

-

Risk Assessment: Before implementing any antiviral management measures, it is essential to conduct a thorough risk assessment to identify potential sources of contamination and determine the level of risk associated with each potential source. This will help companies prioritize their efforts and focus on the most critical areas for control.

-

Training and Education: Employees must receive proper training and education on the importance of antiviral management and how to properly perform tasks related to virus control. This will ensure that everyone understands the protocols and procedures involved in preventing virus transmission in textile production.

-

Equipment and Supplies: Companies must ensure that they have access to the necessary equipment and supplies for antiviral management, including disinfectants, UV lights, heat treatment equipment, and air filtration systems. Proper maintenance and calibration of these equipment are also important to ensure their effectiveness.

-

Regular Monitoring and Audits: Regular monitoring and audits of the production process are essential for identifying any gaps or weaknesses in the antiviral management system. This will help companies identify areas where improvements can be made and ensure that their measures remain effective over time.

Case Study: One example of an effective antiviral management measure in the textile industry is the use of quaternary ammonium compounds (QAC) as a disinfectant agent. QAC is a non-toxic, water-soluble compound that can be used to kill bacteria, fungi, and viruses on textiles. A textile company in China implemented a QAC disinfection program for its production facilities, which resulted in a significant reduction in the incidence of bacterial and viral infections among employees and reduced product defects caused by contaminated fabrics.

Conclusion: Implementing antiviral management measures in textiles is crucial for protecting consumer safety and preventing the spread of infectious diseases. By following a systematic approach that considers risk assessment, employee training, equipment and supplies, and regular monitoring and audits, textile companies can effectively prevent virus transmission in their production processes. With continued investment and innovation in antiviral management strategies, textile industries can continue to play a vital role in safeguarding public health and promoting safe production practices.

随着全球疫情的不断蔓延,纺织品作为日常生活中的重要物品,其抗病毒性能显得尤为重要,为了规范纺织品抗病毒管理,制定相应的管理办法,保障人们的健康与安全,特此编写本篇关于纺织品抗病毒管理办法的英文口语化内容。

纺织品抗病毒管理办法概述

定义与范围

纺织品抗病毒管理办法旨在规范纺织品抗病毒性能的检测、评价、使用及管理,确保纺织品在生产、销售和使用过程中符合相关标准和要求,本管理办法适用于各类纺织品,包括但不限于服装、家居用品、装饰品等。

法律依据

根据相关法律法规,本管理办法作为纺织品抗病毒管理的重要依据,包括《中华人民共和国纺织产品安全法》、《纺织品抗病毒性能评价规范》等。

抗病毒纺织品检测与评价方法

检测方法

(1)物理检测:通过显微镜观察纺织品表面是否存在病毒颗粒,或通过化学分析检测纺织品中是否存在抗病毒成分。

(2)化学分析:采用高效液相色谱法、原子吸收光谱法等化学分析方法,对纺织品进行抗病毒性能评价。

评价标准

(1)检测标准:根据纺织品抗病毒性能的要求,制定相应的检测标准,包括对病毒抑制率、抗细菌性能等指标的评估。

(2)案例分析:以实际案例为例,说明不同纺织品抗病毒性能的评价方法及结果,某品牌服装采用特殊抗病毒面料制作,其抗病毒性能达到国家标准要求。

纺织品抗病毒管理措施

生产环节

(1)加强原材料质量控制:选用无病毒原材料,确保纺织品原料安全可靠。

(2)加强生产过程控制:严格生产流程,确保纺织品在生产过程中的抗病毒性能符合要求。

销售环节

(1)加强市场监管:建立健全市场监管机制,对销售纺织品进行把关。

(2)加强宣传教育:提高消费者对纺织品抗病毒性能的认识和重视程度。

使用环节

(1)遵循使用规范:在使用纺织品时,遵循相关使用规范,确保使用安全。

(2)加强维护保养:定期对纺织品进行维护保养,延长其使用寿命。

抗病毒纺织品案例分析

某品牌服装抗病毒性能案例分析

该品牌服装采用特殊抗病毒面料制作,经过检测证明其抗病毒性能达到国家标准要求,该面料采用高科技纤维材料,具有出色的抗病毒性能和抗菌性能,消费者在使用该服装时,可以放心穿着,无需担心病毒传播的风险。

其他纺织品抗病毒性能案例分析

在实际生活中,还有其他多种类型的纺织品具有抗病毒性能,某些家居用品采用抗菌材料制作,可以有效抑制细菌滋生;某些装饰品采用特殊纤维材料制作,具有较好的抗病毒效果,这些案例表明,抗病毒纺织品的推广和应用具有重要意义。

结论与建议

本管理办法为纺织品抗病毒管理提供了重要依据和参考,为了更好地推广和应用抗病毒纺织品,建议采取以下措施:

-

加强宣传教育,提高消费者对纺织品抗病毒性能的认识和重视程度,通过宣传教育,让消费者了解抗病毒纺织品的优点和作用,引导消费者正确使用和购买抗病毒纺织品。

-

加强监管力度,建立健全市场监管机制,对销售纺织品进行把关,加强对生产、销售环节的监管力度,确保抗病毒纺织品的来源可靠、质量可靠。

-

鼓励企业研发新型抗病毒纺织材料和技术,推动抗病毒纺织品的创新和发展,通过鼓励企业研发新型抗病毒纺织材料和技术,可以推动纺织行业的技术进步和创新发展,提高纺织品的抗病毒性能和品质。

Articles related to the knowledge points of this article:

Textile Expo:A Multi-faceted Showcase of Trends and Opportunities