Understanding the Art of Textile Dyeing

: Exploring the Art of Textile Dyeing,Abstract: This article delves into the intricate process of textile dyeing, a technique that has been used for centuries to impart color and texture onto fabrics. The textural beauty of textiles is often enhanced through dyeing, which involves the application of dyes to fabrics in order to alter their color, tone, and appearance. Through an examination of the various dyeing techniques available, this article explores the significance of each step in the dyeing process, highlighting the importance of selecting the right dyes and ensuring proper mixing and application. Additionally, the article discusses the environmental impact of textile dyeing and the need for sustainable practices in this industry. By understanding the art of textile dyeing, we can appreciate the beauty and complexity of this craft, while also recognizing the need for responsible and eco-friendly practices in the future.

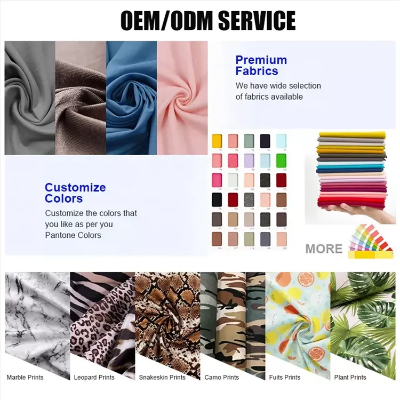

Introduction to Textile Dyeing Textile dyeing is a process used in the manufacturing of textile materials such as clothing, carpets, and upholstery. It involves applying colorants to fabrics using various techniques like dye bathing, pad printing, screen printing, and rotary painting. The primary goal of this process is to impart a desired shade or pattern onto the fabric, enhancing its aesthetic appeal and functionality.

Types of Textile Dyes There are several types of textile dyes available in the market, each with its unique properties and applications. Some of the most common types include:

-

Direct Dyes: These are dyes that can be applied directly onto the fabric by mixing them with the dye bath. They are usually more expensive than other types of dyes but offer better control over color intensity and fastness properties.

-

Indirect Dyes: These dyes are applied through a layer of binder or carrier material, which protects the dye from washing away during the dyeing process. They are cheaper than direct dyes but may require additional steps for finishing.

-

Reactive Dyes: These dyes react chemically with the fibers of the fabric during the dyeing process, resulting in a permanent color. They are widely used in industrial applications where long-lasting colors are required.

-

Emulsion Dyes: These dyes are suspended in an emulsion form, which allows them to penetrate deep into the fabric fibers. They offer excellent coverage and fastness properties but are more difficult to apply than other dyes.

Application Techniques Textile dyeing is carried out using different techniques, each with its own advantages and limitations. Here's a table summarizing some of the most common dyeing methods:

| Technique | Advantages | Disadvantages |

|---|---|---|

| Pad Printing | Easy to use, suitable for small runs | Limited application area |

| Screen Printing | High quality, good coverage | Can be time-consuming |

| Rotary Painting | Fast production rate, low cost | Limited color range |

| Dye Bathing | Controllable color intensity | May require multiple rinses |

Case Study: Implementation of Dye Bathing in the Fashion Industry In the fashion industry, dye bathing has become a popular method for producing vibrant and high-quality garments. For example, a major fashion brand recently implemented dye bathing in their production line to produce new styles of dresses. By using dye bathing, they were able to achieve a consistent color throughout the entire garment, ensuring uniformity and quality across all sizes and shapes. This technique also allowed them to reduce waste by minimizing the need for separate dye baths for different parts of the garment.

Conclusion Textile dyeing is a complex process that requires expertise in both design and application. From direct dyes to reactive dyes, there are various types of textile dyes available that cater to different needs and budgets. Regardless of the type of dye used, proper application techniques and careful consideration of color intensity and fastness properties are essential for achieving successful results. As the fashion industry continues to evolve, so too does the demand for high-quality textiles that meet the latest trends and standards.

在日常生活和商业活动中,纺织品染色是一个重要的环节,纺织品染色是指通过化学或物理方法将天然或人造纤维材料染色,使其具有特定的颜色、图案或风格,本文将详细介绍纺织品染色的基本概念、过程及其重要性。

纺织品染色的基本概念

染色原理

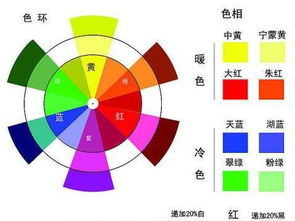

纺织品染色主要依赖于染料,染料是一种能改变纤维颜色的化学物质,通常由颜料和助剂组成,染料通过与纤维表面发生化学反应,使纤维呈现特定的颜色。

染色过程

纺织品染色通常包括准备纤维样品、调配染料、染色、固色和后处理等步骤,在准备阶段,需要选择合适的染料和染色方法以满足特定的需求,在染色过程中,需要控制染料的浓度、温度和时间等参数,以确保染色的效果和质量。

纺织品染色案例说明

天然纤维染色

以天然纤维为例,常见的染色方法包括活性染料染色和直接染料染色,活性染料染色利用染料的活性性质,将纤维染成各种颜色,直接染料染色则是利用染料的颜色鲜艳度和牢度,使纤维具有特定的颜色和图案。

某品牌的一款棉质衣物采用活性染料染色技术,通过选择合适的颜色和工艺参数,使衣物呈现出柔和的蓝色调,同时保持了棉质的柔软和舒适感。

合成纤维染色

对于合成纤维,常见的染色方法包括树脂染色、色母染色等,树脂染色是通过将染料与树脂混合后进行染色,可以获得丰富的颜色和图案效果,色母染色则是将染料预先制成色母颗粒,通过添加到纤维中完成染色。

某品牌的一款丝绸面料采用色母染色技术,通过选择合适的色母配方和工艺参数,使丝绸面料呈现出优雅的紫色调,同时保持了丝绸的柔软和光泽感。

纺织品染色技术及案例分析

纺织染料类型及特点

(1)活性染料:具有鲜艳度高、色泽稳定、易洗快干等优点,适用于各种天然纤维和合成纤维的染色。

(2)直接染料:具有颜色鲜艳、牢度好、环保等优点,适用于各种轻薄型织物的染色。

(3)其他类型的染料:还包括分散染料、硫化染料等,适用于不同材质和颜色的纺织品染色。

纺织品染色技术的应用领域

纺织品染色技术在各个领域都有广泛的应用,包括服装、家居用品、装饰品等,通过不同的染色技术和方法,可以满足不同材质和颜色的纺织品需求。

在服装行业中,纺织品染色技术可以用于制作各种款式和颜色的服装,提高产品的时尚感和个性化程度,在家居用品行业中,纺织品染色技术可以用于制作各种窗帘、地毯等家居装饰品,提高产品的美观度和舒适度。

纺织品染色过程中的注意事项

- 选择合适的染料和工艺参数:根据纺织品的材质、颜色和图案要求选择合适的染料和工艺参数,需要严格控制染料的浓度、温度和时间等参数,以确保染色的效果和质量。

- 注意环保和安全:在纺织品染色过程中,需要注意环保和安全问题,选用环保型染料和助剂,采取有效的环保措施,确保染色过程中的废水和废气等符合环保要求。

- 注意质量控制:在纺织品染色过程中,需要注重质量控制,对染料进行检测和分析,确保染料的品质符合要求,需要对染色后的纺织品进行质量检测,确保其符合相关标准和要求。

纺织品染色是一个重要的环节,对于提高纺织品的品质和美观度具有重要意义,在纺织品染色过程中,需要注意选择合适的染料和工艺参数、注意环保和安全问题、注重质量控制等方面的问题,随着科技的不断进步,纺织品染色技术也在不断发展和创新,为纺织品的生产提供了更多的选择和可能性。

Articles related to the knowledge points of this article:

A Comprehensive Review of Yinchuans Embroidery and Textile Industry

The Story of Dongguans Textile Industry:An Introduction to 东莞依纺织品