The Dynamics of Wuhan Textile Manufacturing:A Comprehensive Analysis

: The Dynamics of Wuhan Textile Manufacturing: A Comprehensive Analysis,Abstract: This paper provides a comprehensive analysis of the textile manufacturing dynamics in Wuhan, China. It discusses the historical evolution of the industry, highlighting its transformation from an industrial hub to a leading center for high-end textile production. The study examines the impact of technological advancements, such as automation and digitalization, on the industry's performance. Additionally, it explores the role of government policies and regulations in shaping the industry's growth trajectory. Finally, the analysis concludes by discussing the future prospects for the industry, including potential challenges and opportunities for innovation and expansion.

Introduction: Wuhan, known as the "Cradle of Chinese Textiles," is a vibrant hub for textile manufacturing. This industry not only contributes to the local economy but also plays a crucial role in the global supply chain. In this article, we will explore the various aspects of Wuhan's textile manufacturing, including its production techniques, market dynamics, and challenges faced by the industry. We will also present an example case study to illustrate how these factors shape the overall performance of the industry.

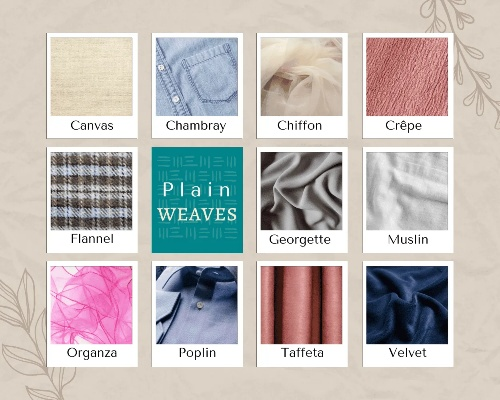

Production Techniques: Wuhan's textile industry is characterized by its advanced production techniques. One of the most significant advancements is the use of digital printing technology, which allows manufacturers to produce high-quality, customized products with greater efficiency. Additionally, the adoption of automation and robotics has significantly reduced labor costs and improved product consistency.

Market Dynamics: The Wuhan textile market is highly competitive, with numerous players vying for a share of the global market. The industry faces challenges such as low profit margins, rising raw material costs, and increasing competition from emerging markets. However, there are also opportunities for growth, such as expanding into new markets or developing niche products.

Challenges Faced by the Industry: One of the main challenges facing the Wuhan textile industry is the lack of innovation. Many companies rely on outdated production methods and technologies, which can lead to lower quality products and increased costs. Another challenge is the need for more skilled workers who can operate modern machinery. Finally, environmental regulations have become increasingly stringent, making it difficult for some companies to comply with standards without investing in new equipment or processes.

Case Study: To illustrate how these factors shape the overall performance of the industry, let's take a look at a successful company that operates in the Wuhan textile market. This company, known as "Textile Innovations," has been able to thrive despite the challenges faced by the industry.

Textile Innovations uses digital printing technology to produce high-quality, customized products that meet the needs of its customers. The company has also adopted automation and robotics to improve efficiency and reduce labor costs. As a result, Textile Innovations has been able to maintain a competitive edge in the market while still achieving higher profit margins.

However, Textile Innovations has also faced challenges in recent years. To address the issue of low profit margins, the company has expanded into new markets and developed niche products that cater to specific customer segments. Additionally, Textile Innovations has invested in research and development to develop new technologies and processes that can help it stay ahead of the competition.

Conclusion: In conclusion, the Wuhan textile industry is a complex and dynamic sector that requires constant innovation and adaptation to remain competitive. By embracing digital printing technology and adopting automation and robotics, companies like Textile Innovations can achieve higher profit margins and remain relevant in the market. However, challenges such as low profit margins, rising raw material costs, and environmental regulations must be addressed if the industry is to continue growing and thriving.

背景介绍

武汉作为中国中部的重要城市,拥有众多纺织品加工厂,为当地经济发展做出了重要贡献,这些工厂不仅专注于生产高质量的纺织品,还积极采用创新技术,推动行业进步,本文将围绕武汉纺织品加工厂展开讨论,介绍其生产流程、技术创新以及实际应用案例。

生产流程概述

- 原料采购:武汉纺织品加工厂从国内外优质供应商采购高质量的原材料,确保产品品质。

- 纺织加工:在先进的纺织机械和工艺的辅助下,对原料进行精细加工,形成各种纺织品。

- 质量控制:工厂重视产品质量,采用严格的质量控制体系,确保每一步生产过程都符合标准。

- 包装与物流:完成纺织品加工后,工厂进行包装和物流处理,确保产品能够及时送达客户手中。

技术创新应用

- 智能化生产:武汉纺织品加工厂引入了先进的自动化生产线,采用机器人和自动化设备进行纺织品的生产,这不仅提高了生产效率,还降低了人为错误。

- 环保材料:随着环保意识的提高,许多纺织品加工厂开始使用环保材料,武汉加工厂在这方面也做出了努力,采用可降解、可回收的材料,减少环境污染。

- 绿色制造:工厂还注重绿色制造,采用节能减排的技术和设备,降低生产成本的同时,也提高了产品的环保性能。

案例分析

以某武汉纺织品加工厂为例,介绍其成功应用创新技术的实际案例。

- 产品创新:该加工厂生产的纺织品采用了新型面料材料,具有优良的透气性和舒适性,该面料还具有抗菌、防螨等特殊功能,满足了现代消费者对高品质纺织品的需求。

- 技术应用:该加工厂采用了先进的智能化生产技术,实现了生产过程的自动化和智能化,这不仅提高了生产效率,还降低了生产成本,该工厂还注重绿色制造,采用节能减排的技术和设备,确保了产品的环保性能。

- 应用效果:该加工厂的产品在市场上受到了广大消费者的欢迎和好评,该工厂还获得了多项荣誉和认证,证明其在纺织品加工领域的技术实力和创新能力。

武汉纺织品加工厂在生产流程、技术创新以及实际应用方面都取得了显著成就,这些成就不仅体现了该工厂在纺织品加工领域的专业性和实力,也体现了其在推动行业进步方面的努力和贡献,武汉纺织品加工厂将继续致力于提高产品质量、降低生产成本、提高生产效率和创新技术应用等方面的工作,为当地经济发展做出更大的贡献。

Articles related to the knowledge points of this article:

10 Tips and Tricks for Effective Textiles Organization

Comprehensive Analysis of Linchang Textile Logistics Route Prices

Immersing Yourself in Realistic and High-Definition Mobile Textile Images